Energy-saving rectification system and energy-saving rectification method for purifying fusel oil

A rectification system and fusel oil technology, applied in the fields of energy-saving rectification and energy-saving rectification systems, can solve the problems of increasing practical difficulty, complicated heat exchange network, increasing compressors, etc., to save equipment investment and not reduce Product quality, heat load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

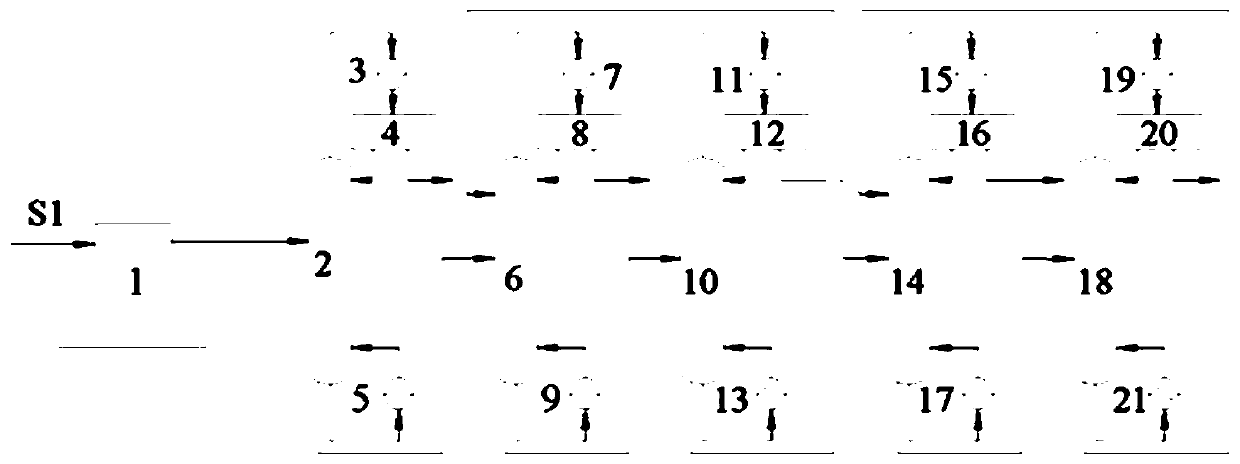

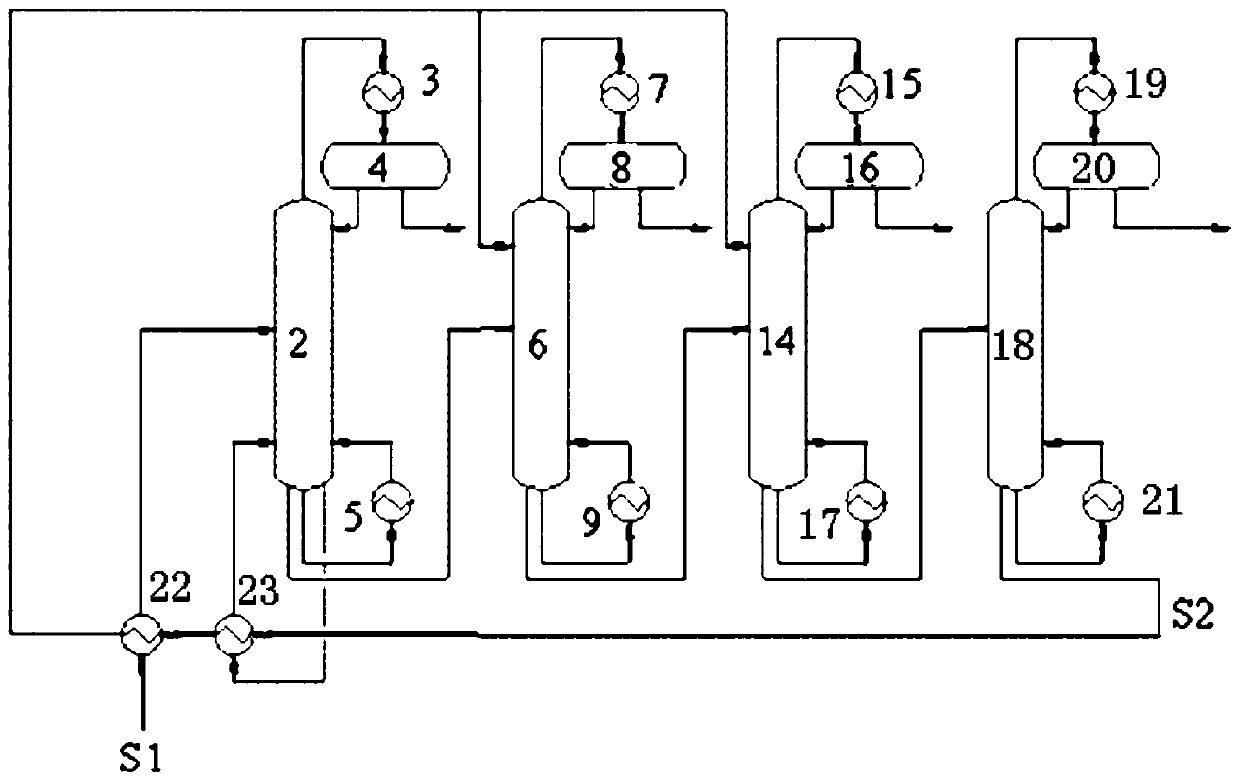

[0027] Still taking the annual processing of 50,000 tons of fusel oil as an example, the feed composition of fusel oil is 40% methanol, 6% ethanol, 2% isopropanol, 2% n-butanol, and 50% water. use as figure 2 As shown in the energy-saving rectification system and rectification method of the present invention, the total system needs to consume 16092.7kw of heat utilities, and the purity of the target product in the output of each tower does not decrease. Therefore, the rectification and purification energy-saving process of the present invention can save 23% of the thermal utility consumption of the whole system.

Embodiment 2

[0031] Still taking the annual processing of 80,000 tons of fusel oil as an example, the feed composition of fusel oil is 30% methanol, 10% ethanol, 5% isopropanol, 5% n-butanol, and 50% water. use as figure 2 As shown in the energy-saving rectification system and rectification method of the present invention, the total system needs to consume 25111.1kw of heat utilities, and the purity of the target product in the output of each tower does not decrease. Therefore, the rectification and purification energy-saving process of the present invention can save 167% of the heat utility consumption of the whole system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com