A control system and control method for compression equipment in a garbage transfer station

A garbage transfer station and control system technology, applied in the field of garbage compression equipment, can solve the problems of increased vehicle load, small loading capacity, and high fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

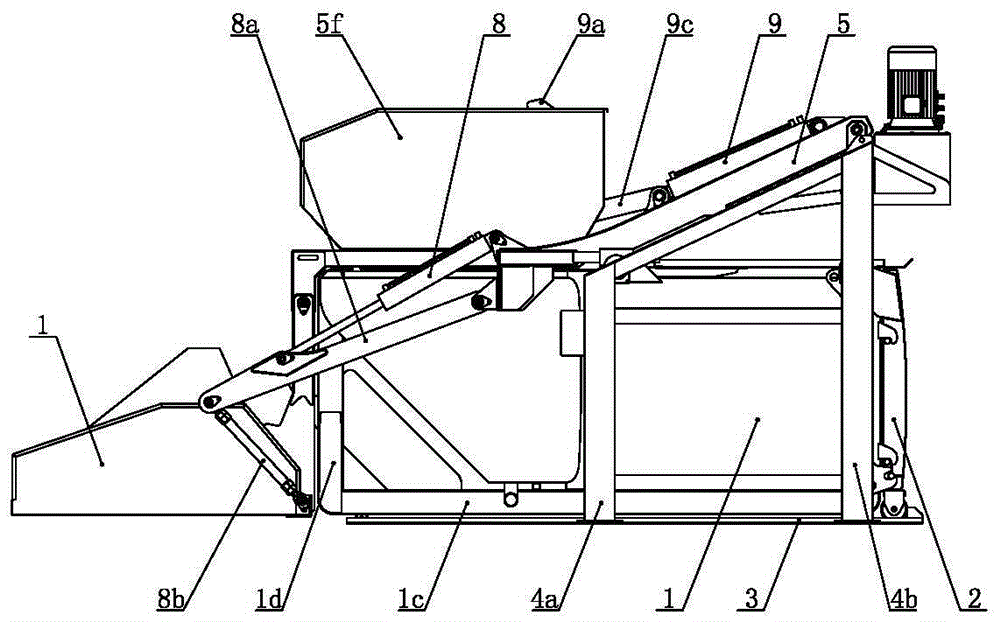

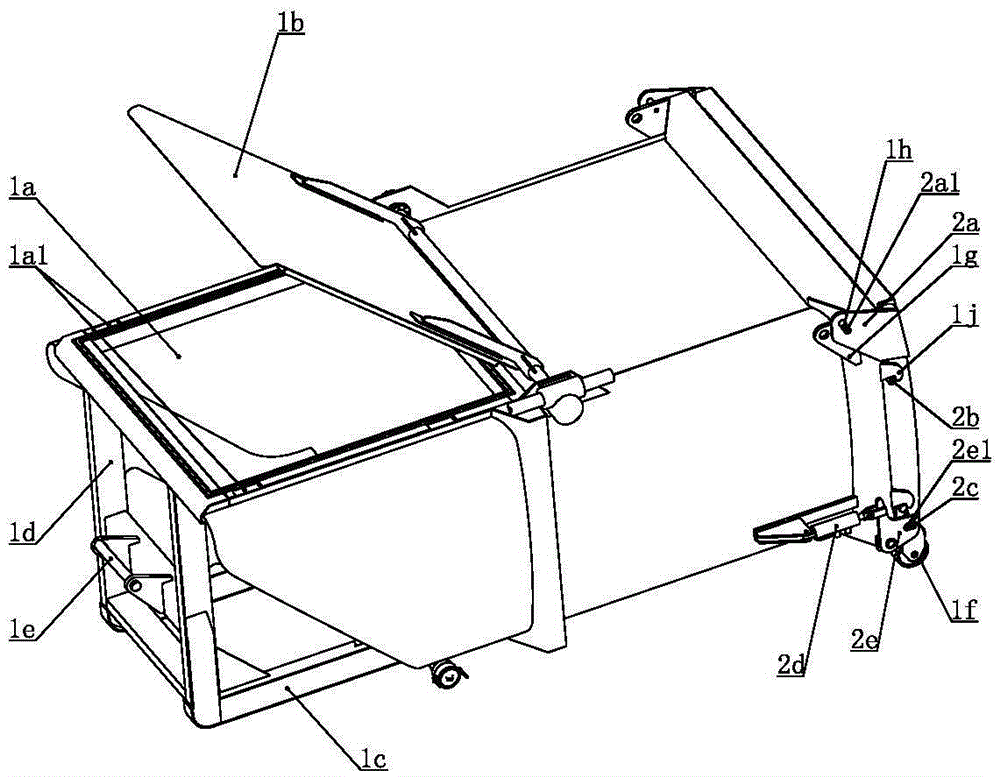

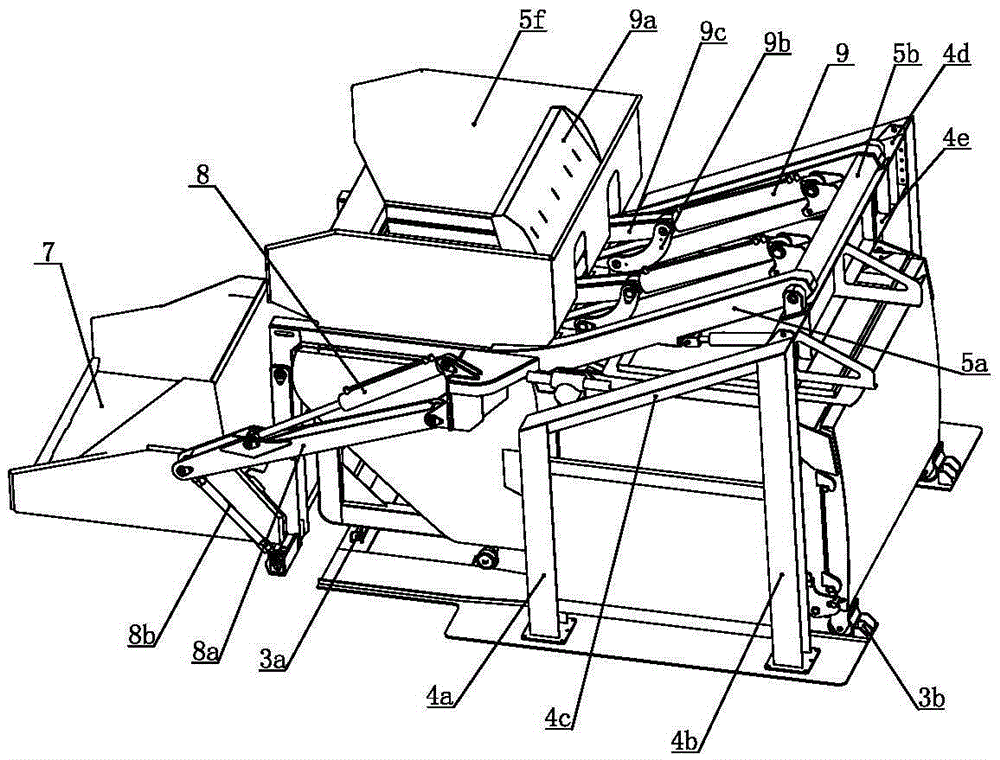

[0034] like Figure 1 to Figure 9 As shown, the compression equipment of the garbage transfer station includes a garbage bin 1, the top surface of the front part of the garbage bin 1 is provided with a feeding opening 1a equal to the width of the garbage bin, and the feeding opening 1a is provided with a top cover 1b that can be opened and closed. The rear door frame of the box 1 is provided with a rear door cover 2 that can be opened and closed. The front of the garbage box 1 is bow-shaped, the bottom of the garbage box 1 is supported on the bottom beam 1c, and the front of the garbage box 1 is provided with a garbage box door frame. 1d is connected with the bottom beam 1c, the garbage bin door frame 1d is welded with a hook 1e that can pull the garbage bin 1, and the roller 1f is installed under the rear door frame, and the roller 1f is supported on the track 3, and the track 3 is fixed on the ground, and the track 3 The rear end of the track 3 is provided with a pit for pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com