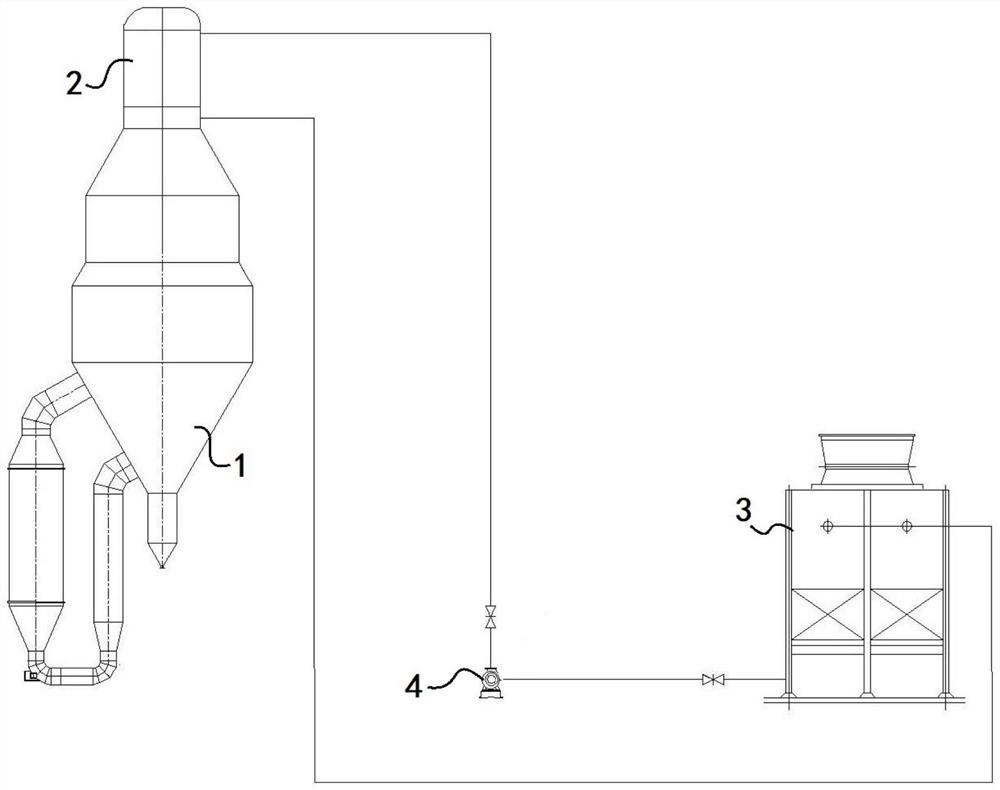

Steam condensation system of evaporation tank

A technology of steam condensation and evaporation tank, which is applied in the direction of evaporation, steam condensation, chemical instruments and methods, etc., which can solve the problems of the rise of the mixed condenser, and achieve the effect of reducing temperature loss, reducing equipment failure rate and leakage rate, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, in which the appended claims is intended to illustrate the principles of the invention, are not intended to limit the scope of the invention.

[0016] Multi-effect vacuum evaporation is very wide, the vacuum system is an important part, and the operational quality of the vacuum system has great impact on production, and many companies have taken a reduced cooling water temperature, increase cooling water, supplemented high Vacuum combination and other measures. The existing vacuum system is multi-mixed condenser (mixed), and the water vapor in the evaporator enters the mixed condenser via the secondary steam pipe, injects cooling water into the cooling water inlet of the hybrid condenser, and mixes with steam through cooling water. Steam is condensed, and the cooling water is discharged after steaming. The water is discharged into the hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com