Pipe and bag combined dust collector

A bag filter and composite technology, which is applied in combination devices, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of inability to dynamically adjust operating load, high oil content in flue gas, increase in flue gas moisture, etc. Condensation possible, reduced cleaning frequency, reduced humidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

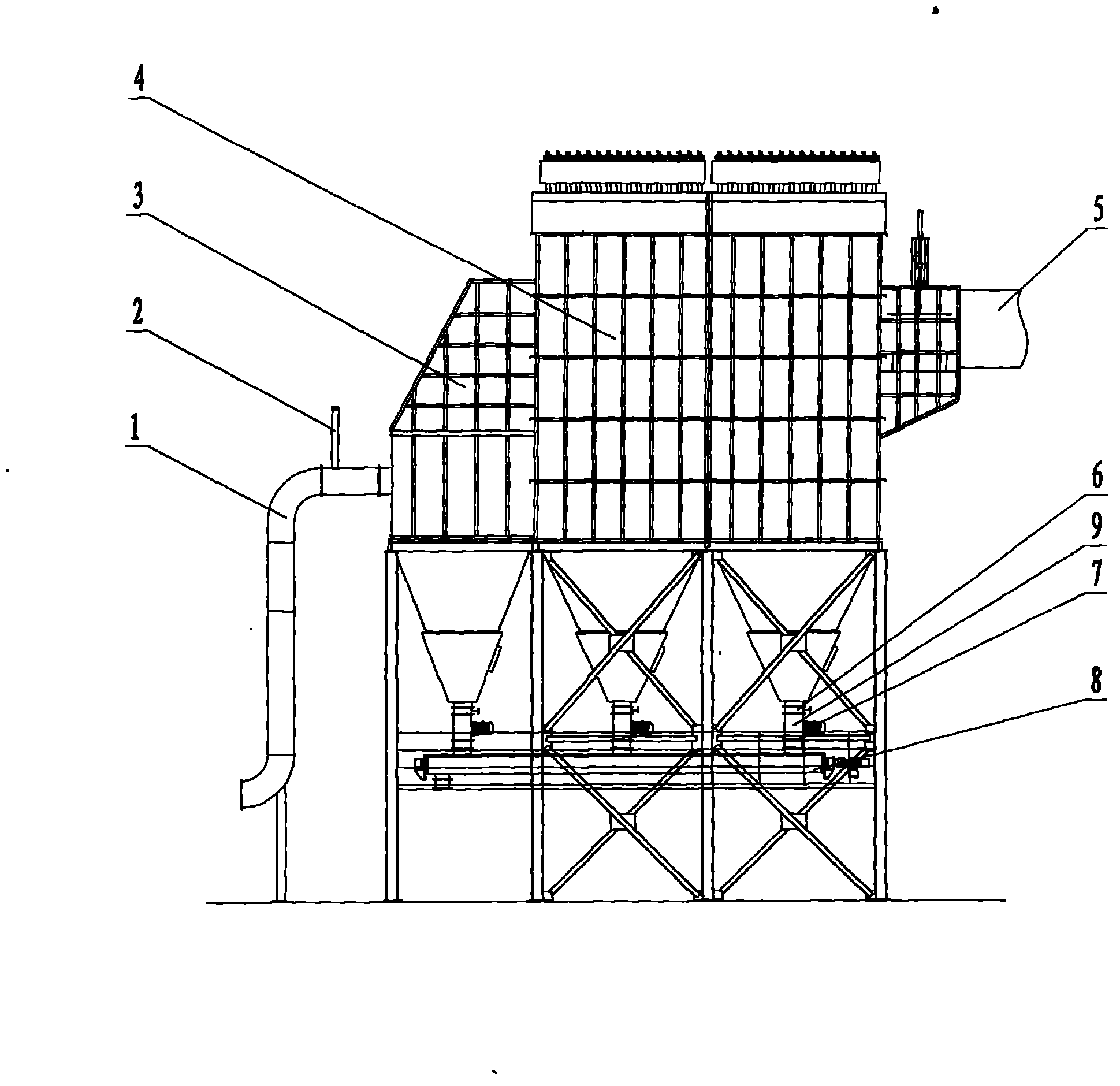

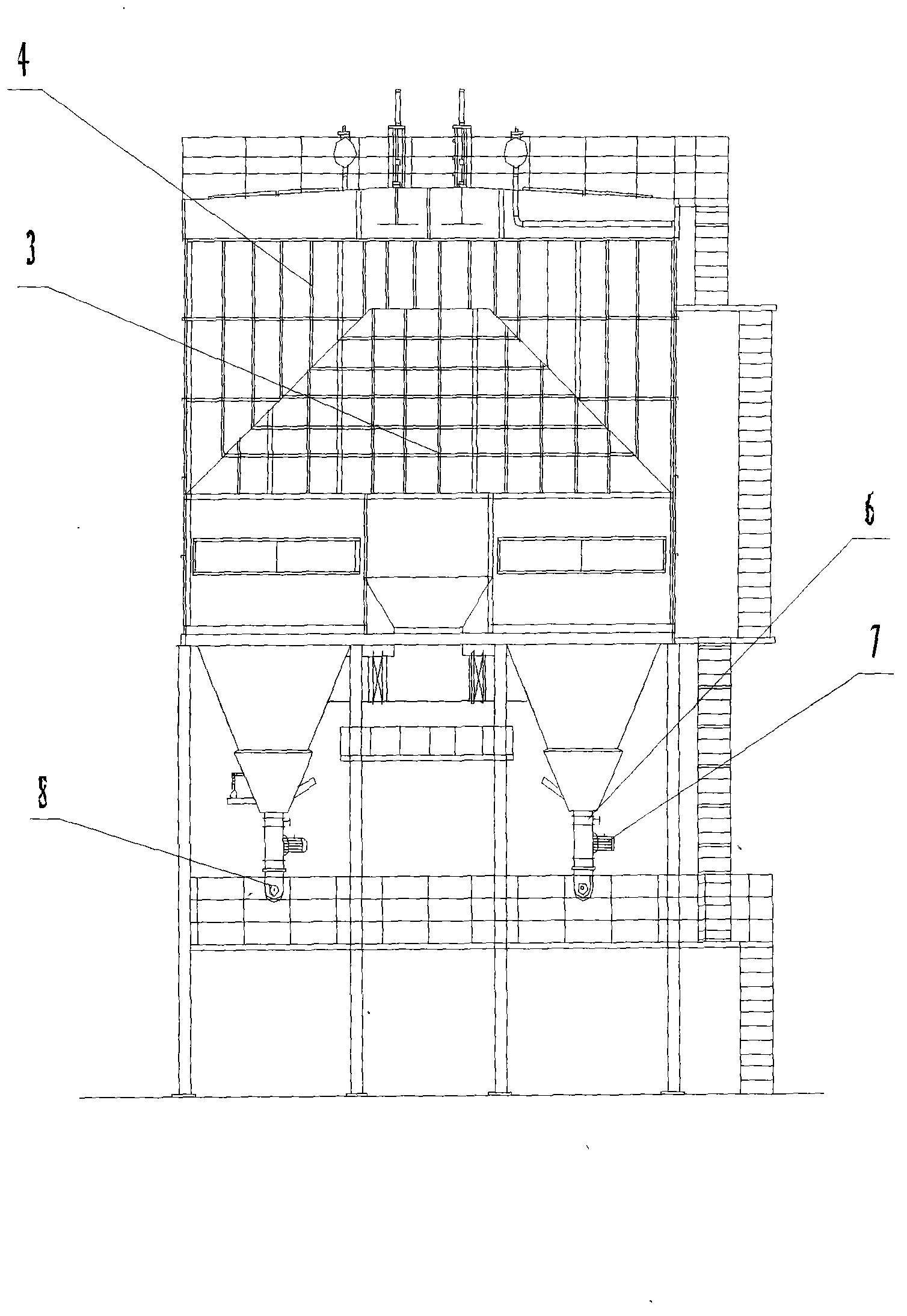

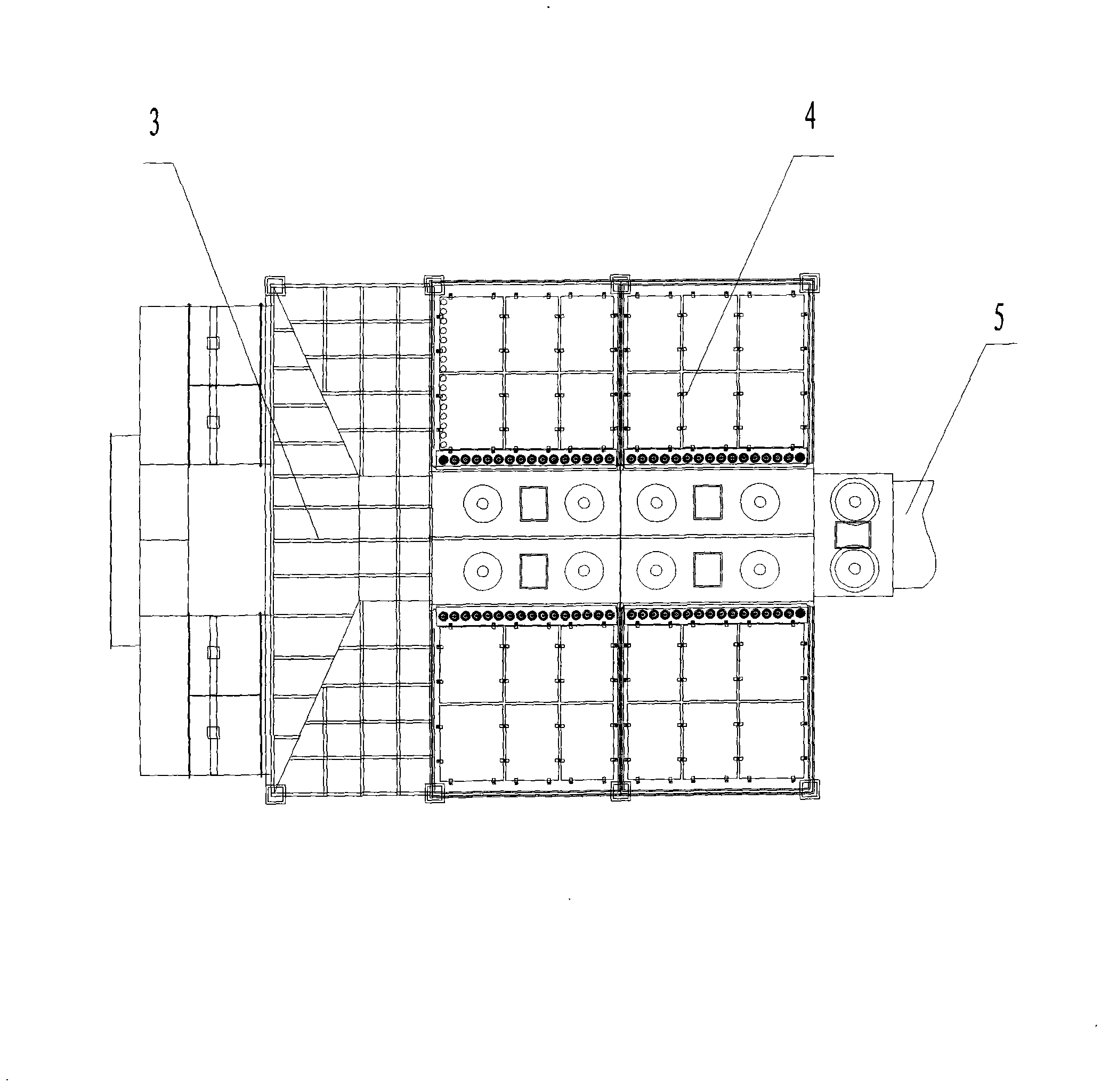

[0023] Such as Figure 1-3 As shown, a tube-bag composite dust collector described in the embodiment of the present invention includes a multi-tube cyclone dust collector 3 and a bag filter 4, and the multi-tube cyclone dust collector 3 is arranged on one side of the bag filter 4. The multi-pipe cyclone dust collector 3 is connected with the inlet flue 1, and the inlet flue 1 is provided with a plug plate 2, and the other side of the bag filter 4 is provided with an outlet flue 5, and the bag filter 4 passes through several conveying pipes 9 and The screw conveyor 8 is connected, and the conveying pipeline 9 is provided with a star feeder 7 , and the top of the conveying pipeline 9 is provided with a manual flapper valve 6 close to the connection with the bag filter 4 .

[0024] During work, the flue gas to be treated enters the present invention through the inlet flue 1; first enters the multi-pipe cyclone dust collector 3, and performs primary treatment on the large particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com