A kind of auxiliary support device and adjustment method for flexible structure processing and trimming

A flexible structure and auxiliary support technology, applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of no description or report, no data collected, etc., to eliminate chatter and improve processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

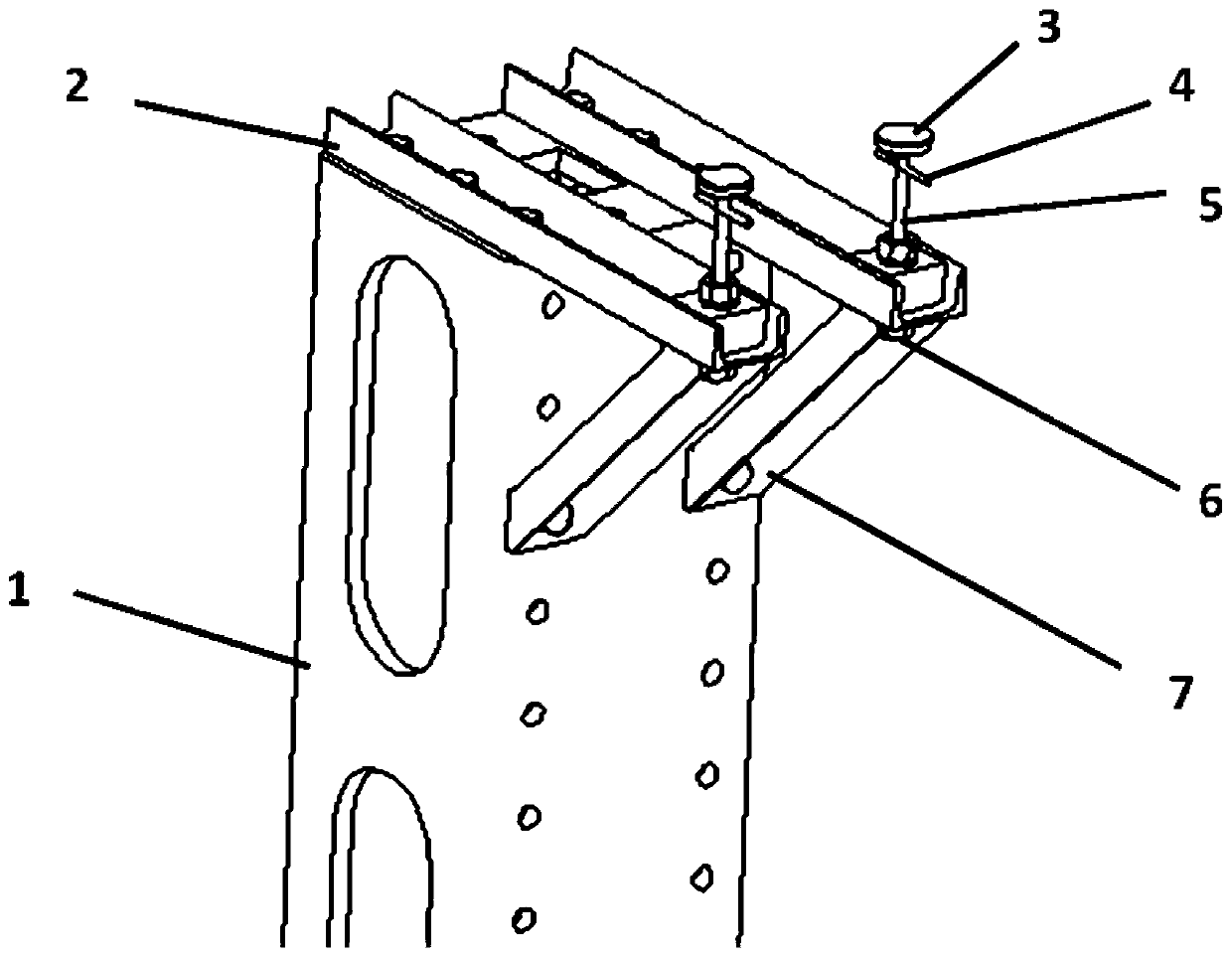

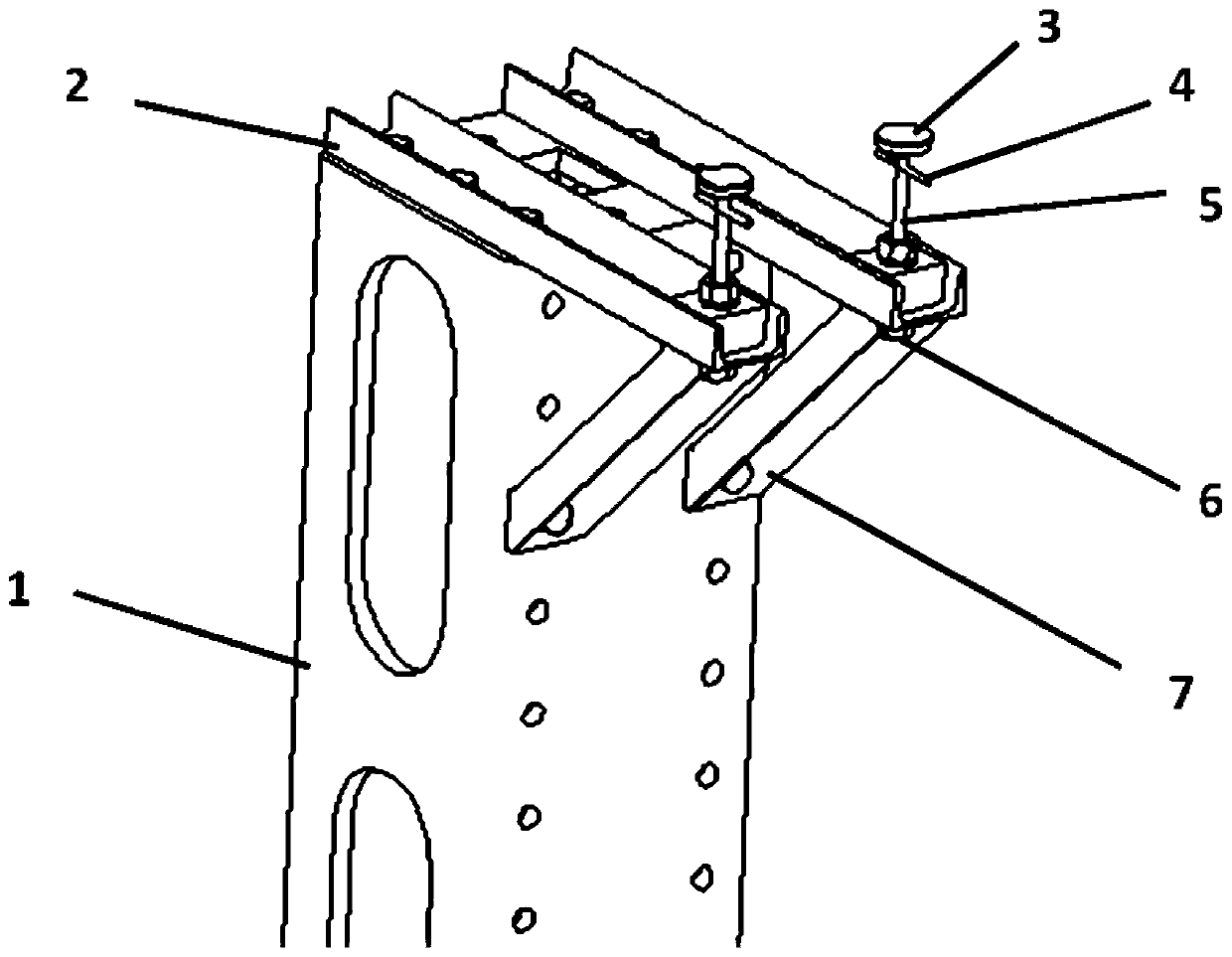

[0026] figure 1 It is a perspective view of an auxiliary support device during the process of processing and trimming the flexible structure of the cantilever. As shown in the attached figure, the device includes: a column 1, a horizontal fixing rod 2, a rubber pad 3, a rotating rod 4, a supporting rod 5, a nut 6 and Oblique fixed rod 7. The column 1 is made of cast iron; the horizontal fixed rod 2 and the oblique fixed rod 7 are processed by channel steel; the rotating rod 4 and the support rod 5 are processed by carbon steel; the nut 6 is a standard part.

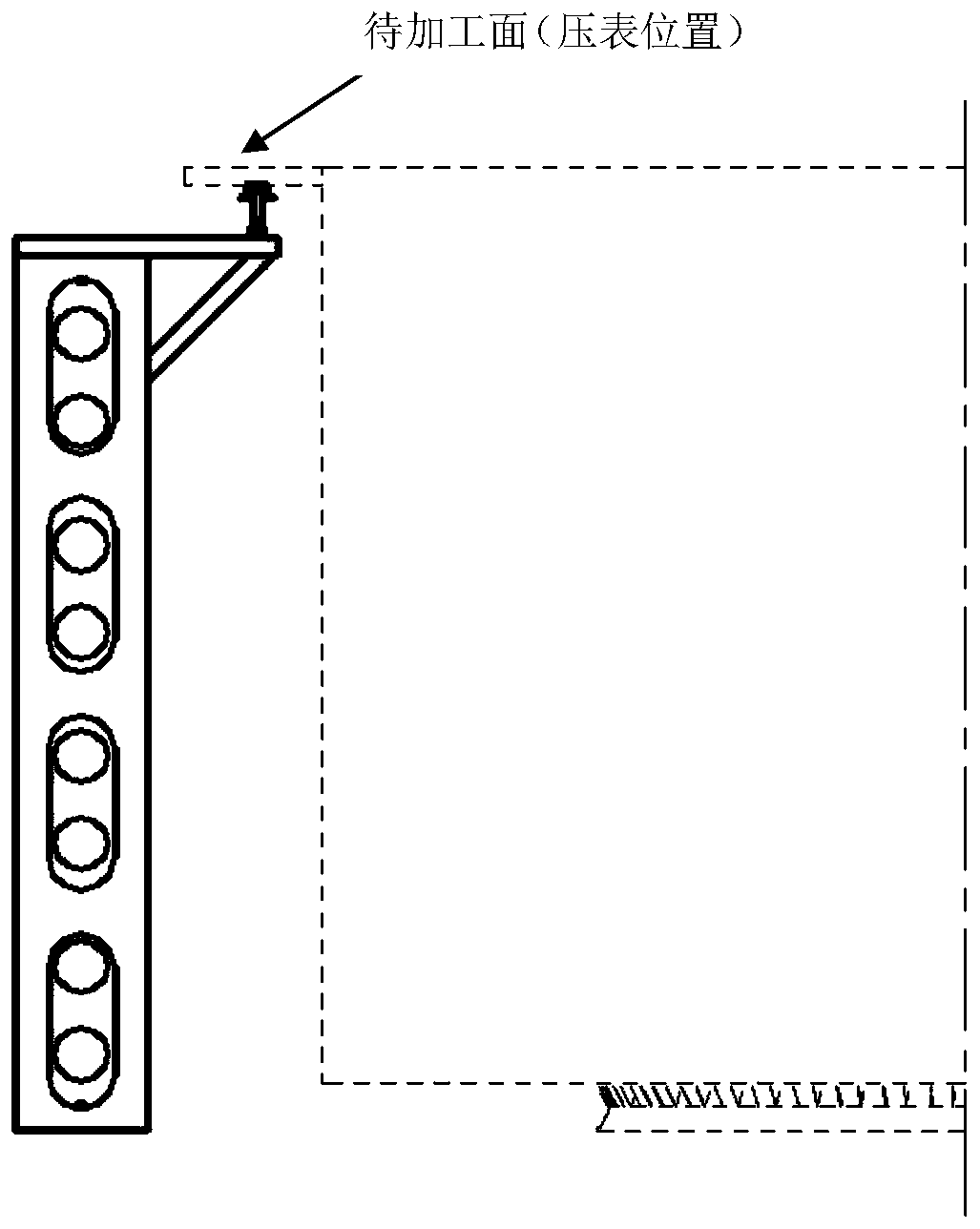

[0027] Place the auxiliary supporting device provided by the present invention under the flexible structure to be processed during the processing and trimming of the cantilever flexible structure, and adjust according to the adjustment method for the auxiliary supporting device for processing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com