Composite airborne equipment stand for aircraft

A technology of composite materials and airborne equipment, which is applied to aircraft parts, transportation and packaging, and can solve problems such as reducing structural weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution can also be realized through the following technical measures and the present invention will be further described below in conjunction with the accompanying drawings:

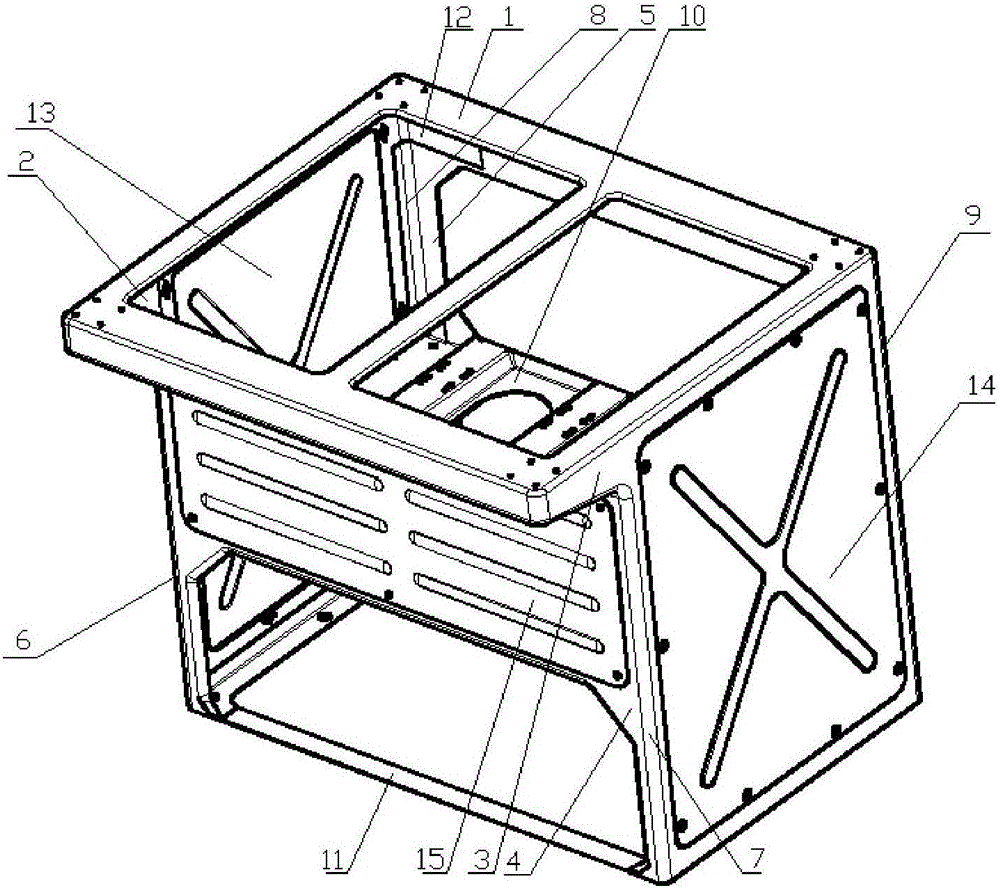

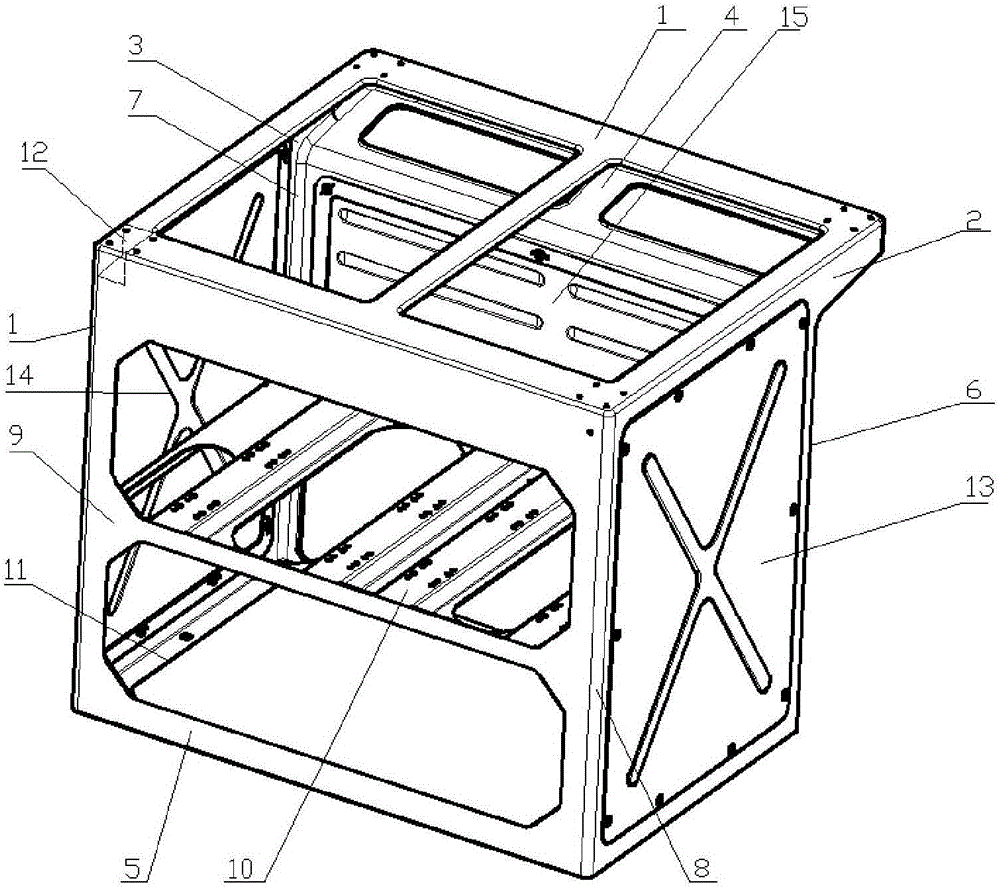

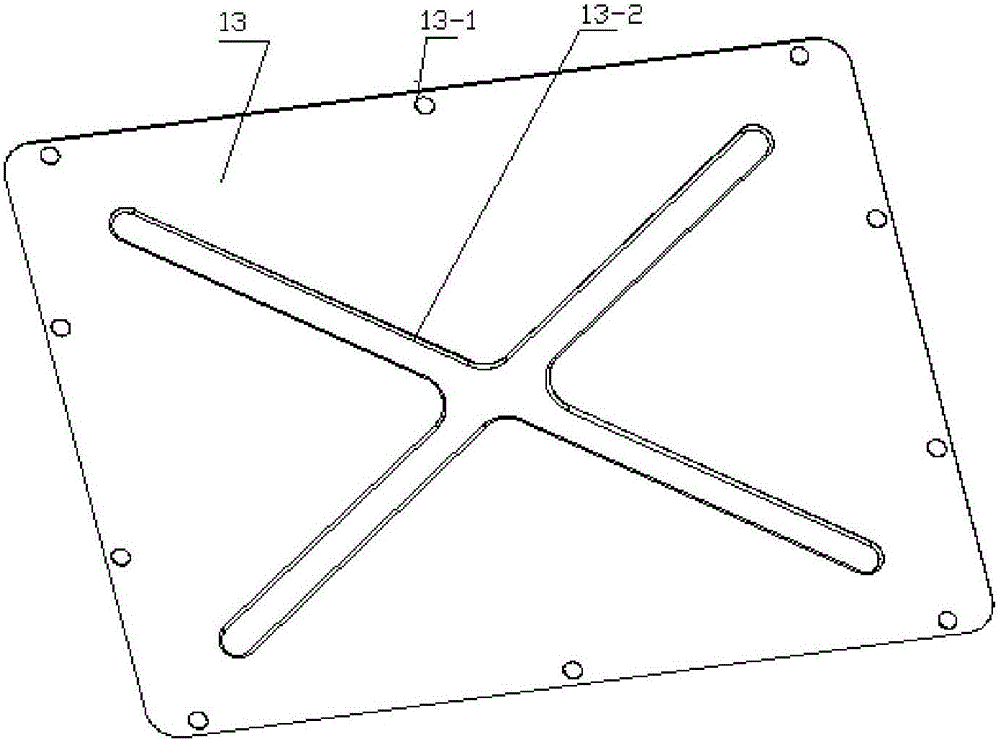

[0014] figure 1 It is a schematic diagram of the front three-dimensional structure of the present invention, figure 2 It is a schematic diagram of the three-dimensional structure of the back side of the present invention, a composite material airborne equipment stand for aircraft, consisting of an upper panel 1, a left wing panel 2, a right wing panel 3, a front panel 4, a rear panel 5, a left front support column 6, and a right front support column 7. The left rear support column 8, the right rear support column 9, the middle partition 10, the bottom plate 11, the corner reinforcement plate 12, the left maintenance opening cover 13, the right maintenance opening cover 14, and the front maintenance opening cover 15, It is characterized in that: the main frame structure of the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com