A magnetorheological support method for blisk processing

A support method and magnetorheological technology, applied in the directions of blade support elements, metal processing equipment, metal processing machinery parts, etc., can solve the problems of weak rigidity and poor processing accuracy, and achieve improved local rigidity, good supporting effect, and processing. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail in conjunction with the drawings and technical solutions.

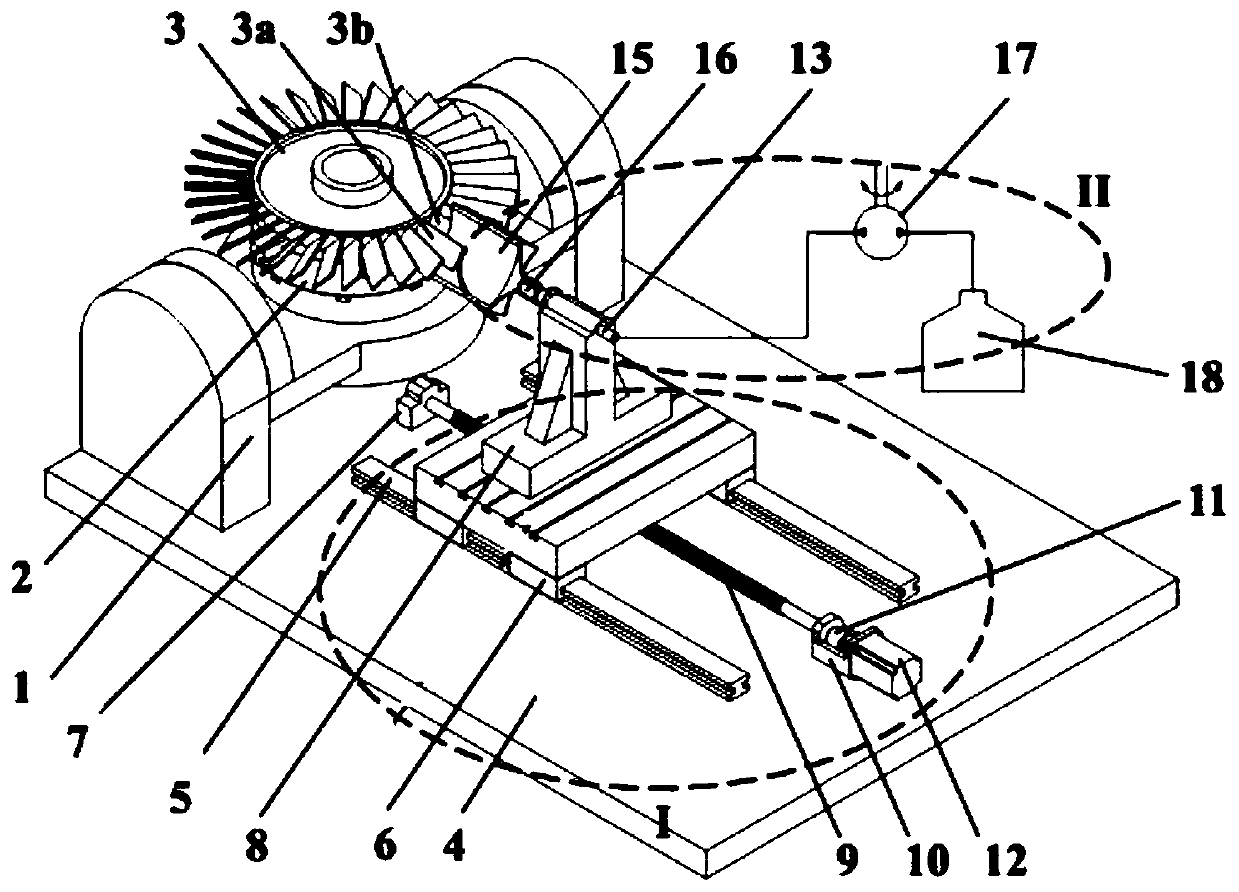

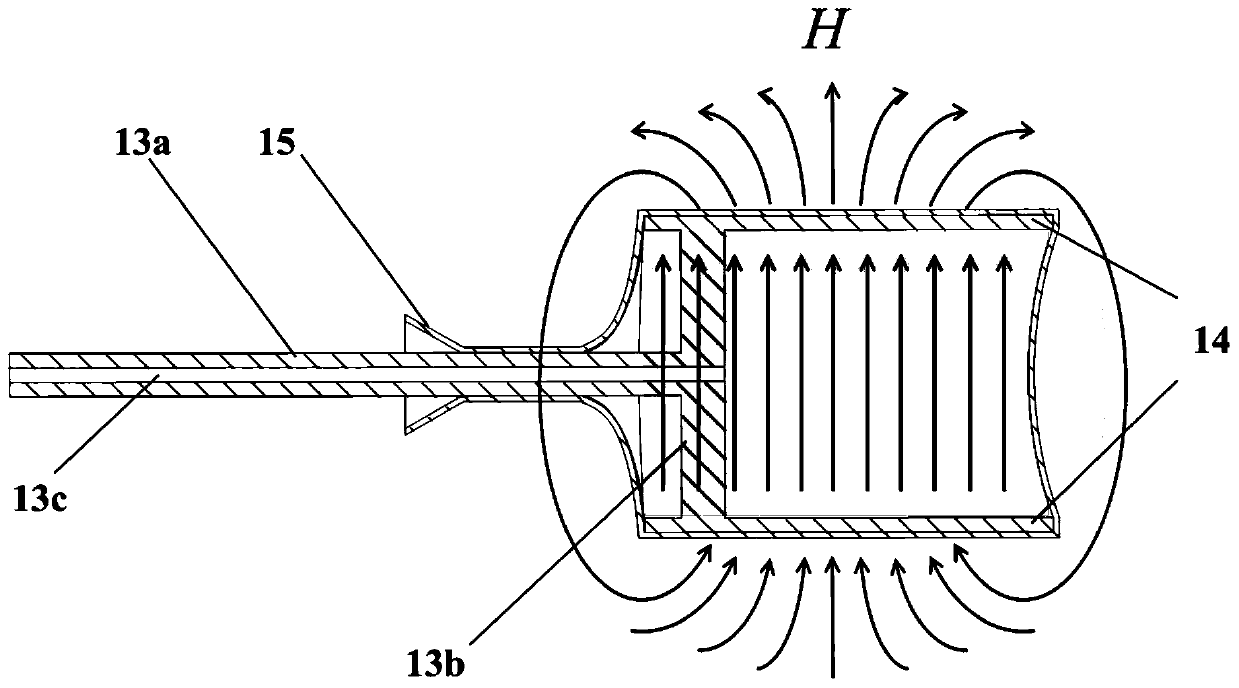

[0020] In the embodiment, figure 1 is a schematic diagram of the overall structure of the magnetorheological fluid support device, figure 2 It is a sectional view of the magnetorheological support mechanism II. Wherein, the skeleton 13 is made of non-magnetic aluminum alloy material, the permanent magnet 14 is made of RuFeB strong magnetic material, and the permanent magnet 14 contains a magnetic switch. The magnetorheological fluid 18 is made of 40% volume fraction of carbonyl iron powder and 60% volume fraction of silicone oil, with a density of 3.55g / ml.

[0021] The assembly steps of the magnetorheological fluid support device are as follows:

[0022] First install the linear feed mechanism I, install the linear guide rail 5 on the fixed workbench 4, install the slide seat 6 on the linear guide rail 5, and fasten the lead screw bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com