Back-feed type film digit television omnidirectional reception antenna

A digital TV and receiving antenna technology, applied in the direction of electrical short antennas, antennas, resonant antennas, etc., can solve the problems of unfavorable antenna miniaturization, large size, and large antenna volume, and achieve easy processing and use, light weight, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

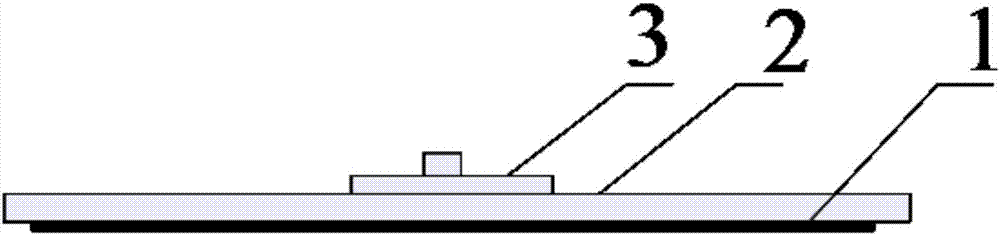

[0017] see figure 1 , 2 , a kind of back-feed film type digital TV omnidirectional receiving antenna, comprising a dielectric substrate 2, a single-arm thin-film copper foil 1 attached to the front of the dielectric substrate and electrically connected to a feeder plate 3 fixed on the back of the dielectric substrate in parallel, the thin-film copper The foil is wound in a counterclockwise direction and attached in parallel to the dielectric substrate in a helical ribbon shape.

[0018] The thin-film copper foil that is wound counterclockwise in the form of a spiral ribbon and is parallel attached to the front of the dielectric substrate has a winding angle θ of 7×π, a total length of 910 mm, and an initial width of 1.8 mm. The outermost ring of copper foil The radius is 95mm, and the width of the thin film copper foil gradually increases from the starting point, and it becomes "suddenly truncated" at the widest point at the end. Since the gain of the helical antenna mainly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com