Large-torque equal-wall-thickness screw drilling tool with motors in serial connection

A technology of screw drilling tools and equal wall thickness, which is used in drilling equipment, earth-moving drilling, driving devices for drilling in wellbore, etc. Working life, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

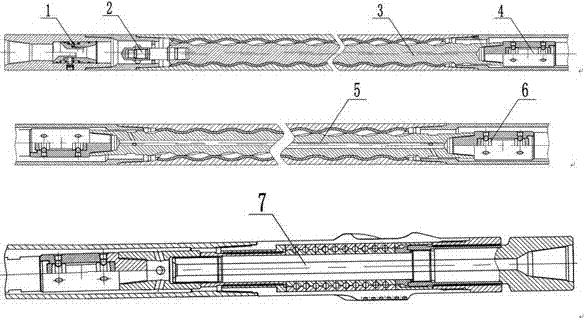

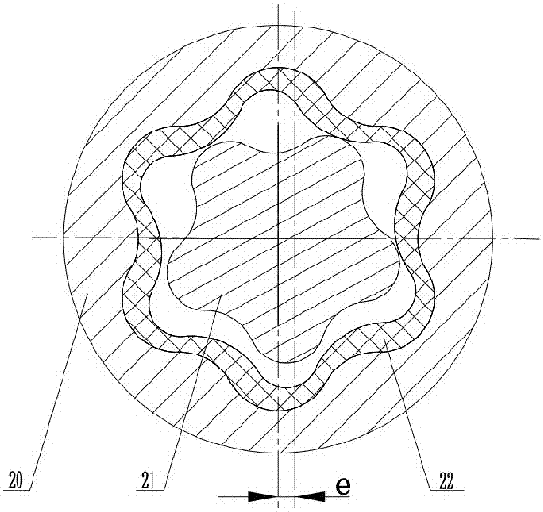

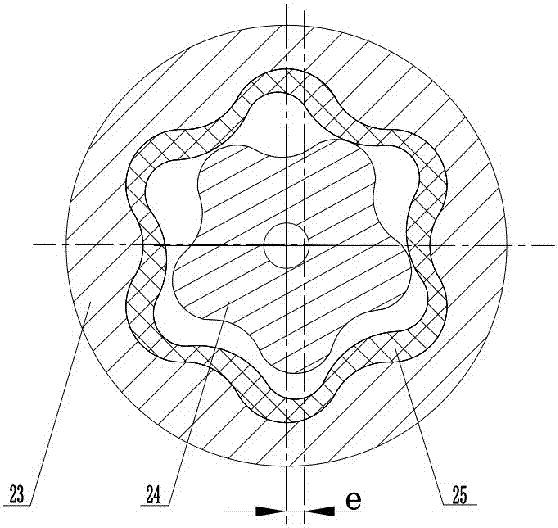

[0017] Such as figure 1 As shown, the present invention adopts the following technical solutions: a high-torque serial hollow motor equal-wall screw drilling tool, mainly composed of a bypass valve assembly 1, an anti-drop assembly 2, a motor assembly 3, and a cardan shaft assembly I4 , hollow rotor motor assembly 5, cardan shaft assembly II 6, transmission shaft assembly 7, the bypass valve housing, anti-drop joint housing, stator housing, cardan shaft housing, and transmission shaft housing are partially passed through Improve the double-shoulder NC56 buckle connection to enhance the connection strength of the shell. The series part is composed of 2 motor assemblies of different stages and 2 cardan shaft assemblies of the same size. The motor assembly 3 is a 3.5-stage stator and rotor Coordination, the hollow rotor motor assembly 5 is a two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com