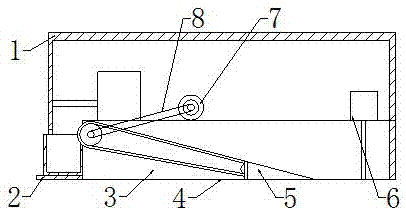

Bridge gap residue removing device with water spraying device

A technology of water spraying device and clearing device, which is applied in the direction of road surface cleaning, cleaning methods, construction, etc. It can solve the problems affecting the health of cleaners and pedestrians, affecting the expansion and contraction of bridges, and unfavorable bridge maintenance, so as to achieve strong cleaning power, easy operation, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

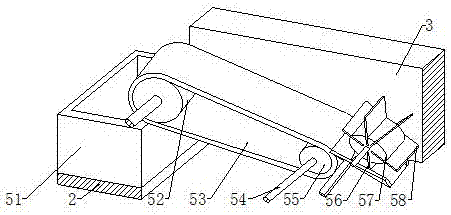

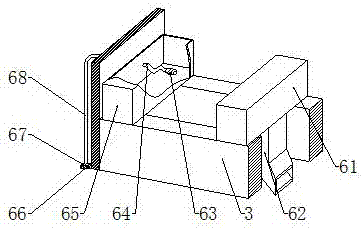

[0027] Specific implementation method: the staff fills up the water in the water tank 65 before use, is full of accumulator, connects the power supply of motor 7 during use, and negative pressure vacuum cleaner 61 starts to work, and fine residue is cleaned up by dust guide head 62, The design prevents the fine dust from being scattered in the air during the cleaning process, and solves the problem in the prior art that the fine dust is scattered in the air during the residue cleaning process and endangers people's health.

[0028] After the power supply of the motor 7 is turned on, the motor 7 drives the rotating shaft 54 to rotate, and the rotating shaft 54 connected to the drum 57 drives the drum 57 to rotate, thereby driving the cleaning brush 58 to move around the rotating shaft 54, and then sweeps the residue in the gap of the bridge into the guide plate 56 , the residue on the guide plate 56 continues to rise with the movement of the cleaning brush 58 until it falls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com