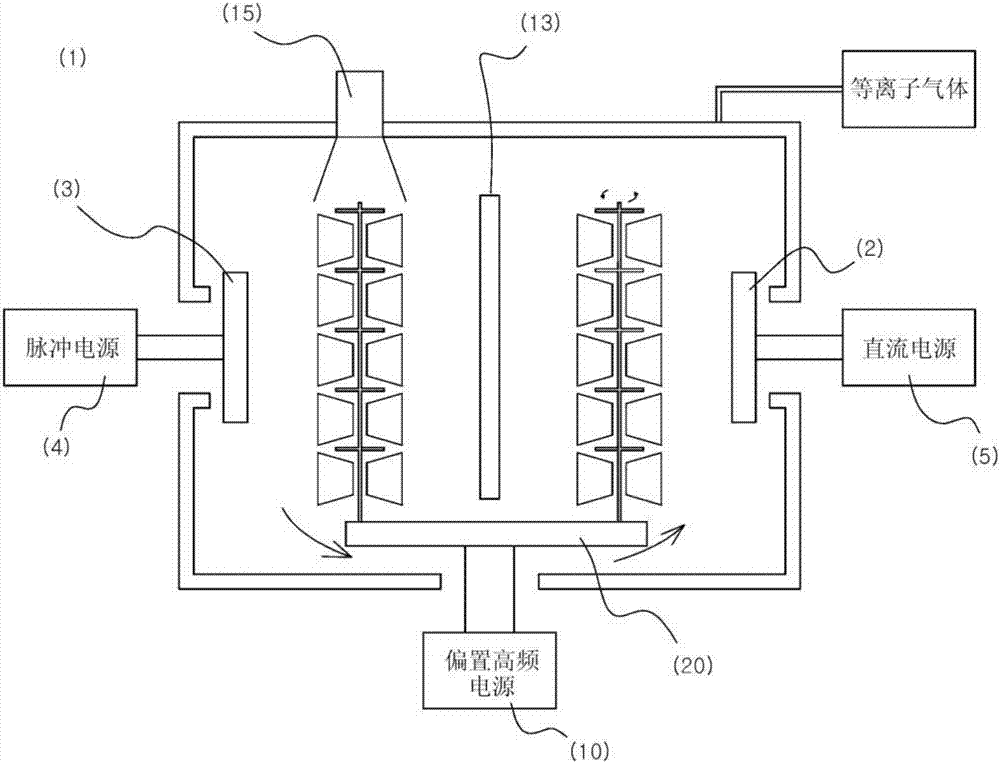

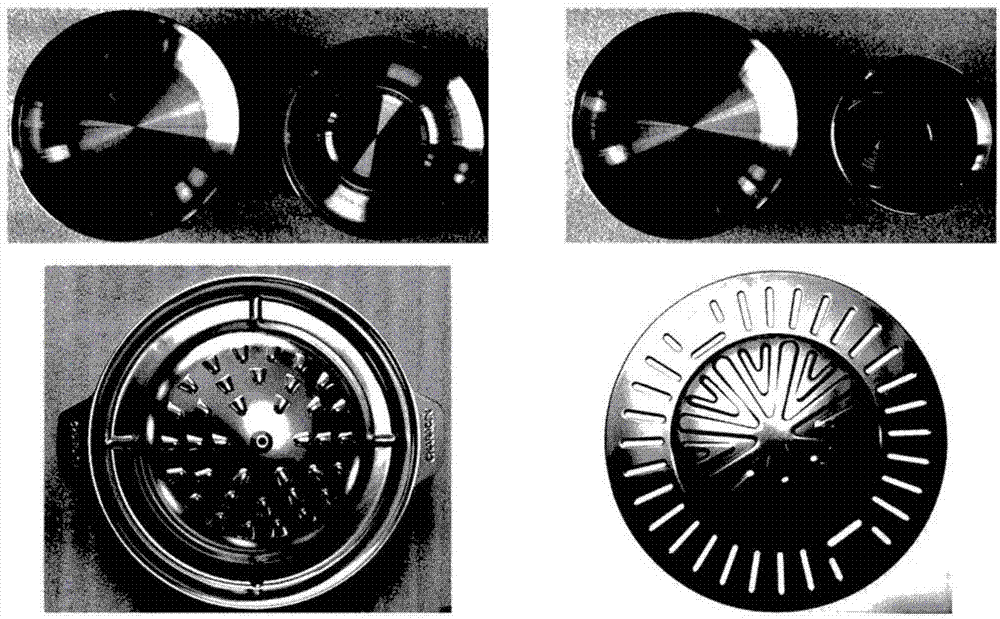

A method for production of dishware using plasma hybrid deposition system

A plasma and manufacturing method technology, applied in the field of tableware, can solve the problems of reduced corrosion resistance and wear resistance, corrosion, wear, etc., to increase corrosion resistance and wear resistance, improve antibacterial ability, and simple drying process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The terminology used in the present invention is based on the consideration of the functions in the present invention, and the general terms that are currently used are selected as much as possible, but this may vary according to the intentions or examples of those skilled in the art, the emergence of new technologies, etc. different.

[0027]In addition, there are also terms arbitrarily selected by the applicant in specific cases, and in such cases, the meanings thereof are described in detail in the description of the related invention. Therefore, the terms used in the present invention should be defined based on the meanings of the terms and the entire content of the present invention, rather than simply based on the names of the terms.

[0028] Throughout the specification, when it is stated that a certain component "includes" a certain component, unless there is a specific statement to the contrary, it means that other components are not excluded but may be include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com