Nanometer self-cleaning coating and preparation method thereof

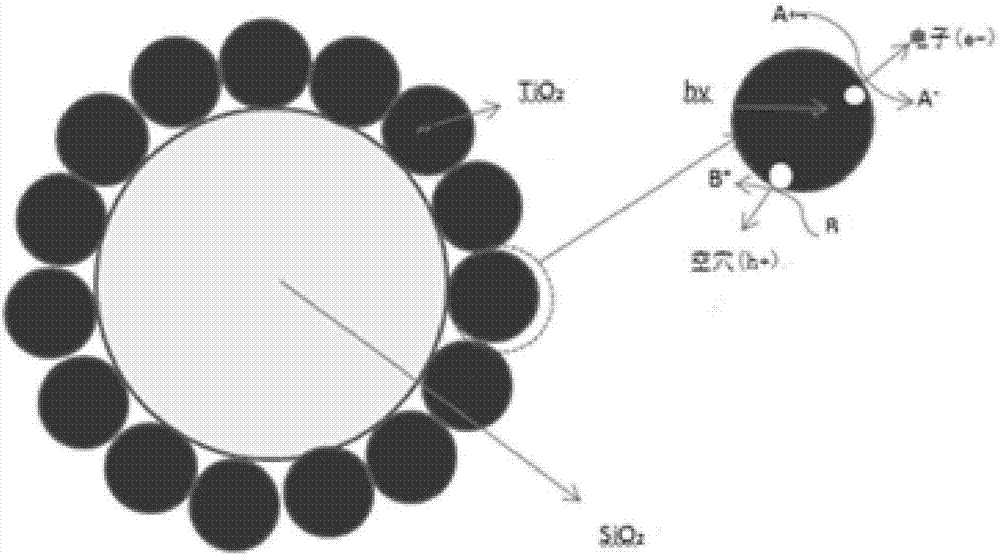

A nanometer self-cleaning and coating technology, applied in the field of hydrophobic materials and photocatalytic materials, can solve the problems of no photocatalytic effect, inability to degrade organic pollutants, low transmittance, etc., achieving simple and easy preparation and breaking through climate. Limiting, mildly conditioned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Dissolve 0.6 g of azobisisobutyronitrile (initiator) in 30 mL of o-xylene (organic solvent) to obtain an initiator solution. Take 2 / 3 of the initiator solution and place it in a 250mL four-necked flask equipped with an electric stirrer, a thermometer and a condenser.

[0030] Step 2: Heat 5mL trifluoroethyl methacrylate (fluorine-containing functional monomer) to 60°C under stirring, mix 15mL methyl methacrylate and 5mL butyl acrylate (soft and hard monomer) Drop the funnel into the four-neck flask. The dropping time is controlled at about 45min. After the dropwise addition of the monomer was completed, the remaining initiating solution (1 / 3) was added and reacted at a constant temperature of 60° C. for 1.5 hours.

[0031] Step 3: Dissolve 0.6g of water-based acrylic resin and 0.2g of azobisisobutyronitrile in 30mL of acetone, quickly add to fluorine-modified acrylic resin at 50-60°C, and react for 6-8 hours. Until the color gradually becomes transparent, a h...

Embodiment 3

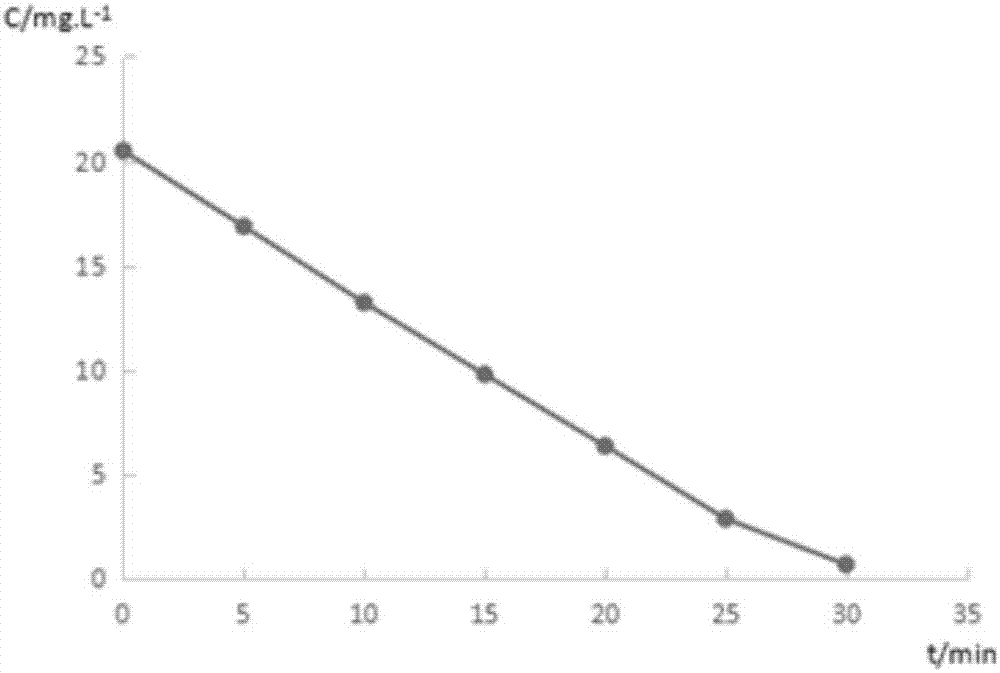

[0040] This embodiment is basically the same as embodiment 1, the difference is that adding SiO 2 / TiO 2 The mass of the composite nano-hydrophobic particles is 1.0g, the contact angle of the obtained coating is 102°, and the transmittance corresponds to Figure 5 In the 5% curve, the transmittance can reach 70%.

Embodiment 4

[0042] This embodiment is basically the same as Embodiment 1, except that 2.80 g of nano-titanium dioxide (SiO 2 The mass ratio to the nanometer photocatalyst is 0.5), the nanocomposite particle synthesis step appears deposition, the product has a small amount of nanometer titanium dioxide, and the contact angle of the obtained coating is 130°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com