A kind of preparation method of phosphorus and nitrogen synergistic water-soluble polymer flame retardant

A water-soluble polymer and flame retardant technology, applied in the application field of functional polymer materials, can solve the problems of easy phase separation, difficult to dissolve in solvents, easy to migrate, etc., achieve simple production process conditions, and overcome the deterioration of mechanical properties. , Improve the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

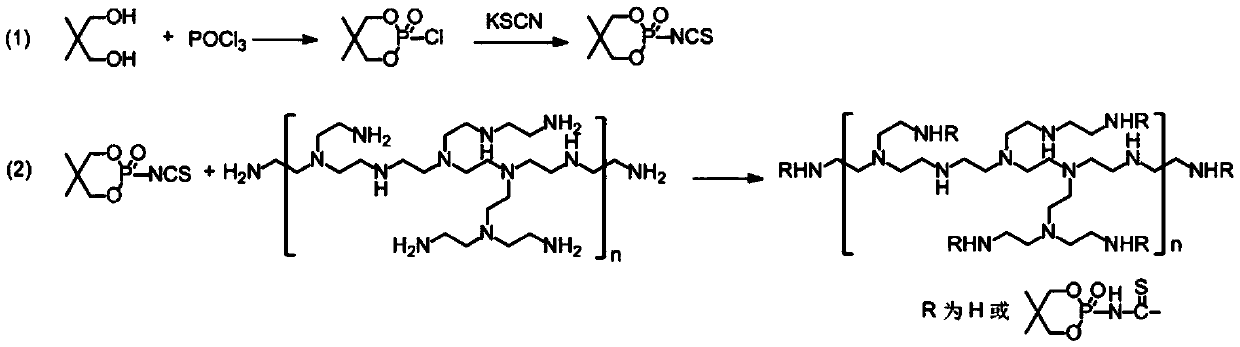

[0021] (1) First, 10.4 g of neopentyl glycol and 9.3 mL of phosphorus oxychloride were dissolved in 1,2-dichloroethane, refluxed at 85° C. for 10 hours, rotary evaporated, and dried to obtain white phosphorus-containing intermediate 5, 5-Dimethyl-2-chloro-1,3,2-dioxaphosphocaprolactoyl phosphate;

[0022] (2) Afterwards, 18.5g of 5,5-dimethyl-2-chloro-1,3,2-dioxaphosphacaprolactoyl phosphate obtained in step (1) was dissolved in 9.7g of potassium thiocyanate In acetone solution, reflux at 60°C for 4 hours, remove potassium chloride by filtration, and obtain 5,5-dimethyl-2-isothiocyanato-1,3,2-dioxaphosphacaprolactoyl phosphate filtrate ;

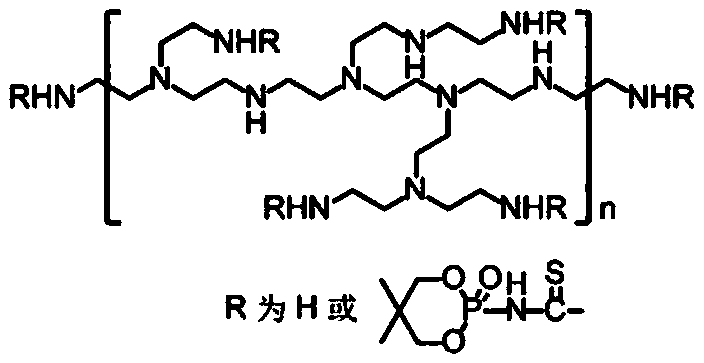

[0023] (3) 5,5-dimethyl-2-isothiocyanate-1,3,2-dioxaphosphacaprolactoyl phosphate filtrate that step (2) obtains adds 10 g molecular weight again and is 600Da large Molecular nitrogen-containing intermediate polyethyleneimine, reacted for 6 hours, suction filtered, and dried to obtain a yellow-brown powdery phosphorus-nitrogen synergistic ...

Embodiment 2

[0025] (1) First, dissolve 10.4g of neopentyl glycol and 18.6mL of phosphorus oxychloride in dichloromethane, reflux at 85°C for 8 hours, rotary steam and dry to obtain the white phosphorus-containing intermediate 5,5-dimethyl -2-Chloro-1,3,2-dioxaphosphacaprolactoyl phosphate;

[0026] (2) Afterwards, 18.5g of 5,5-dimethyl-2-chloro-1,3,2-dioxaphosphacaprolactoyl phosphate obtained in step (1) was dissolved in 9.7g of potassium thiocyanate In 1,2-dichloroethane solution, reflux at 60°C for 6 hours, remove potassium chloride by filtration, and obtain 5,5-dimethyl-2-isothiocyanato-1,3,2-phosphorus dioxide Heterocaprolactoyl phosphate filtrate;

[0027] (3) 5,5-dimethyl-2-isothiocyanate-1,3,2-dioxaphosphacaprolactoyl phosphate filtrate that step (2) obtains adds 15g molecular weight again and is 1800Da macromolecule The nitrogen-containing intermediate, polyethyleneimine, was reacted for 10 hours, suction filtered, and dried to obtain a yellowish-brown powdery phosphorus-nitrog...

Embodiment 3

[0029] (1) First, dissolve 10.4g of neopentyl glycol and 37.2mL of phosphorus oxychloride in acetone, reflux at 85°C for 6 hours, rotary steam and dry to obtain the white phosphorus-containing intermediate 5,5-dimethyl-2 - Chloro-1,3,2-dioxaphosphacaprolactoyl phosphate;

[0030] (2) Afterwards, 18.5g of 5,5-dimethyl-2-chloro-1,3,2-dioxaphosphacaprolactoyl phosphate obtained in step (1) was dissolved in 9.7g of potassium thiocyanate In 1,2-dichloroethane solution, reflux at 60°C for 8 hours, remove potassium chloride by filtration, and obtain 5,5-dimethyl-2-isothiocyanato-1,3,2-phosphorus dioxide Heterocaprolactoyl phosphate filtrate;

[0031] (3) 5,5-dimethyl-2-isothiocyanate-1,3,2-dioxaphosphacaprolactoyl phosphate filtrate that step (2) obtains adds 18g molecular weight again and is 25000Da macromolecule The nitrogen-containing intermediate, polyethyleneimine, was reacted for 12 hours, suction filtered, and dried to obtain a yellow-brown powdery phosphorus-nitrogen synerg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com