Preparation method and application of a kind of bio-based oil-condensing material

A bio-based, condensed oil technology is applied in the field of preparation of bio-based condensed oil materials, which can solve the problems of difficult to achieve large-scale production, complex preparation process, secondary environmental pollution, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a, placing the wheat bran in a NaOH solution with a concentration of 1 mg / mL for 5 hours to obtain pretreated wheat bran;

[0021] b. Add 0.1wt% nano-silica to an alkaline ethanol mixed solution containing 4wt% vinyltrimethoxysilane coupling agent and sonicate for 1 hour to obtain a prefabricated mixed solution;

[0022] c. Add the pretreated wheat bran obtained in step a to the prefabricated mixed solution obtained in step b, stir evenly, then pour it into a container and seal it, put it into an oven to heat, the temperature is 80°C, and the holding time is 4 hours, to obtain Wheat bran modified with silane coupling agent;

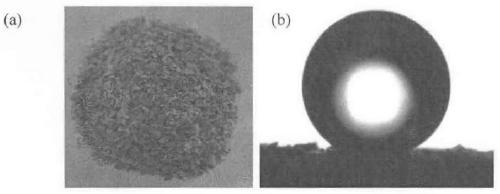

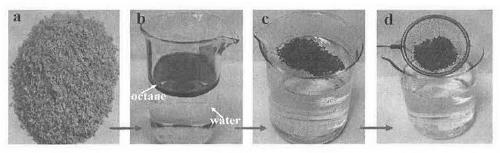

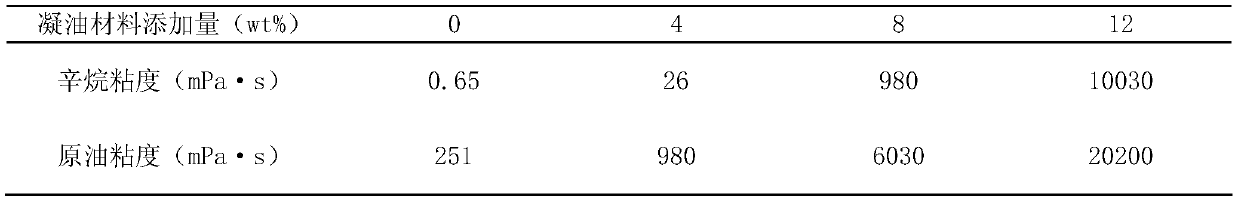

[0023] d, the wheat bran modified by the silane coupling agent obtained in step c is added to the styrene monomer containing 0.05g / mL, in the ethyl acetate mixed solution of 0.05wt% azobisisobutyronitrile, stirred evenly, and then transferred to In a closed container, react at a temperature of 80° C. for 48 hours, and obtain a bio-based oil-conden...

Embodiment 2

[0028] a, placing the wheat bran in a KOH solution with a concentration of 2 mg / mL for 4 hours to obtain pretreated wheat bran;

[0029] b. adding 0.2wt% nano-titanium dioxide to an alkaline ethanol mixed solution containing 5wt% vinyltrichlorosilane coupling agent and ultrasonicating for 2 hours to obtain a prefabricated mixed solution;

[0030] c. Add the pretreated wheat bran obtained in step a to the prefabricated mixed solution obtained in step b, stir evenly, then pour it into a container and seal it, then put it in an oven to heat at a temperature of 90°C and a holding time of 3 hours to obtain Wheat bran modified with silane coupling agent;

[0031] d. Add the wheat bran modified by the silane coupling agent obtained in step c to the divinylbenzene containing 0.1mg / mL, 0.1wt% azobisisobutyronitrile in the mixed solution of ethyl acetate, stir evenly, and then transfer to In a closed container, react at a temperature of 100°C for 36 hours, and the bio-based oil-condens...

Embodiment 3

[0036] a, placing wheat bran in a NaOH solution with a concentration of 3 mg / mL for 3 hours to obtain pretreated wheat bran;

[0037] b. Add 0.3wt% nano-zinc oxide to an alkaline ethanol mixed solution containing 6wt% vinyl tri-tert-butoxysilane coupling agent and sonicate for 3 hours to obtain a prefabricated mixed solution;

[0038] c. Add the pretreated wheat bran obtained in step a to the prefabricated mixed solution obtained in step b, stir evenly, then pour it into a container and seal it, put it into an oven to heat, the temperature is 100°C, and the holding time is 2 hours, Obtain the wheat bran modified by silane coupling agent;

[0039] d, the wheat bran modified by the silane coupling agent obtained in step b is added to the styrene monomer containing 0.13mg / mL, in the ethyl acetate mixed solution of 0.3wt% azobisisoheptanonitrile, stirred evenly, and then transferred to In a closed container, react at a temperature of 120°C for 24 hours, and the bio-based oil-cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com