Fenton's reagent oxidation wastewater treatment method and device thereof

A technology for oxidizing wastewater and treatment methods, which is applied in the direction of oxidized water/sewage treatment, special compound water treatment, water treatment parameter control, etc. It can solve the problems of high operational difficulty, difficulty, and reduced treatment effect, and reduce the difficulty of manual operation. , reduce processing costs, and stabilize the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

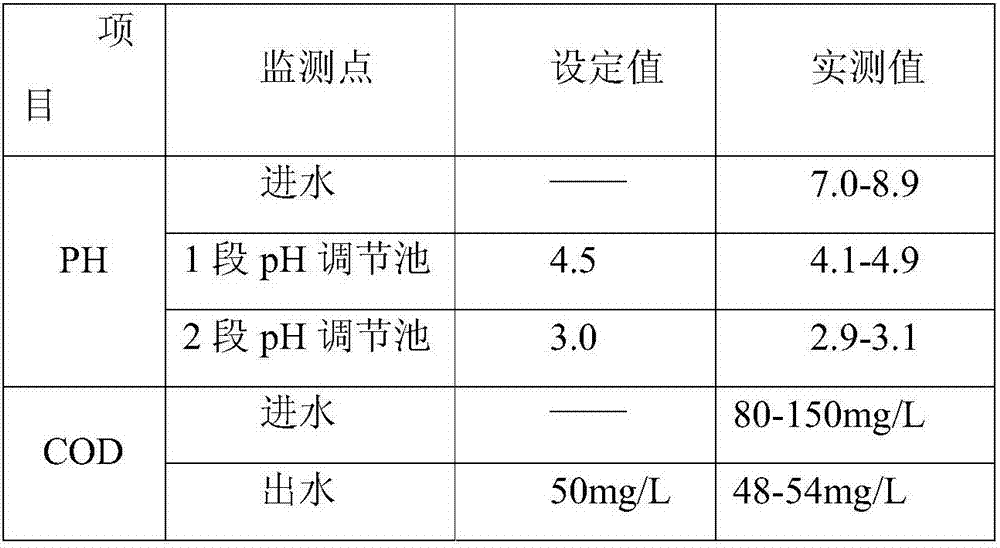

[0031] Concentrated water produced by the reverse osmosis unit in the sewage reuse workshop of an oil refinery: water volume 80-110m 3 / h, COD is 80-180mg / L, pH is 7.0-8.9. The treatment method and device provided by the present invention are used to treat it: the waste water enters the first section of pH adjustment tank, and the first acid pump extracts 98% sulfuric acid from the concentrated acid storage tank to roughly adjust the pH of the waste water, and the effluent enters the second section of pH Adjusting tank, the second acid pump pumps 30% dilute sulfuric acid from the dilute acid storage tank to fine-tune the pH of the wastewater. Add 27.5% hydrogen peroxide and 20% ferrous sulfate to the ferrous sulfate storage tank. After 3 hours of oxidation, the effluent is extracted from the liquid caustic storage tank by the alkali pump to adjust the pH by 30%, and finally enters the sedimentation tank for solidification. Discharge after liquid separation.

[0032] See Tabl...

Embodiment 2

[0039] The wastewater produced by the styrene-butadiene plant of a rubber factory has undergone biochemical treatment and the water quality: the water volume is 220-300m 3 / h, COD is 76-150mg / L, pH is 6.9-8.5. The treatment method and device provided by the present invention are used for treatment: the waste water enters the first-stage pH adjustment tank, and the first acid pump pumps 98% sulfuric acid from the concentrated acid storage tank to adjust the pH of the waste water to 5.0, and the effluent enters the second-stage pH adjustment The second acid pump pumps 30% dilute sulfuric acid from the dilute acid storage tank to fine-tune the pH of the wastewater to 3.2. After the effluent enters the oxidation reaction pool, the first and second dosing pumps respectively collect the Add 27.5% hydrogen peroxide and 20% ferrous sulfate to the storage tank and the ferrous sulfate storage tank. After 3 hours of oxidation, the effluent will be pumped out 30% of the liquid caustic sod...

Embodiment 3

[0047] Wastewater from a printing and dyeing factory: water volume 50-75m3 / h, COD 5000-8000mg / L, pH 10-10.9. The treatment method and device provided by the present invention are used to treat it: the waste water enters the first section of pH adjustment tank, and the first acid pump extracts 98% sulfuric acid from the concentrated acid storage tank to roughly adjust the pH of the waste water, and the effluent enters the second section of pH Adjusting tank, the second acid pump pumps 30% dilute sulfuric acid from the dilute acid storage tank to fine-tune the pH of the wastewater. Add 27.5% hydrogen peroxide and 20% ferrous sulfate to the ferrous sulfate storage tank. After 3 hours of oxidation, the effluent is extracted from the liquid caustic storage tank by the alkali pump to adjust the pH by 30%, and finally enters the sedimentation tank for solidification. Discharge after liquid separation.

[0048] See Table 5 for the process parameter setting and monitoring results of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com