Pd@MOFs/TiO2 photocatalyst, and preparation method and application thereof

A photocatalyst and hydrothermal reaction technology, which is applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of high photogenerated electron-hole recombination rate, To achieve the effect of improving photocatalytic efficiency and separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of MIL-101: Add 4.002g of chromium nitrate nonahydrate and 1.661g of terephthalic acid into 70ml of aqueous solution A, stir at room temperature for 0.5h, then add 0.5ml of hydrofluoric acid solution B into mixed solution A , mixed and stirred for 0.5h, transferred the mixed solution C to the polytetrafluoroethylene reactor liner, then put the polytetrafluoroethylene reactor liner into the high-pressure reactor, and reacted at 220°C for 10h under high temperature and high pressure, and then put The solution was filtered through a 250-mesh stainless steel filter, washed three times with DMF and deionized water, and dried under vacuum at 150°C to finally obtain MIL-101.

[0033] Preparation of Pd@MIL-101: Add 0.1g of MIL-101 to 20mL of petroleum ether organic solution, ultrasonically mix, stir at room temperature for 30min to obtain solution A, then add 0.404ml of H 2 PdCl 4 Add dropwise to the stirring solution A, continue stirring at room temperature for 3 ...

Embodiment 2

[0035] Preparation of MIL-101: Add 4.000g of chromium nitrate nonahydrate and 1.660g of terephthalic acid into 60ml of aqueous solution A, stir at room temperature for 0.5h, then add 2ml of hydrofluoric acid solution B into mixed solution A, Mix and stir for 0.5h, transfer the mixed solution C to the polytetrafluoroethylene reactor liner, then put the polytetrafluoroethylene reactor liner into the high-pressure reactor, react at 220°C for 12h under high temperature and high pressure, and then put the solution Filter through a 250-mesh stainless steel filter, wash with DMF and deionized water three times, and vacuum-dry at 150°C to finally obtain MIL-101.

[0036] Preparation of Pd@MIL-101: Add 0.1g of MIL-101 to 20mL of petroleum ether organic solution, ultrasonically mix, stir at room temperature for 30min to obtain solution A, then add 0.404ml of H 2 PdCl 4 Add dropwise to the stirring solution A, continue stirring at room temperature for 3 h, then add 0.0378 g of sodium bo...

Embodiment 3

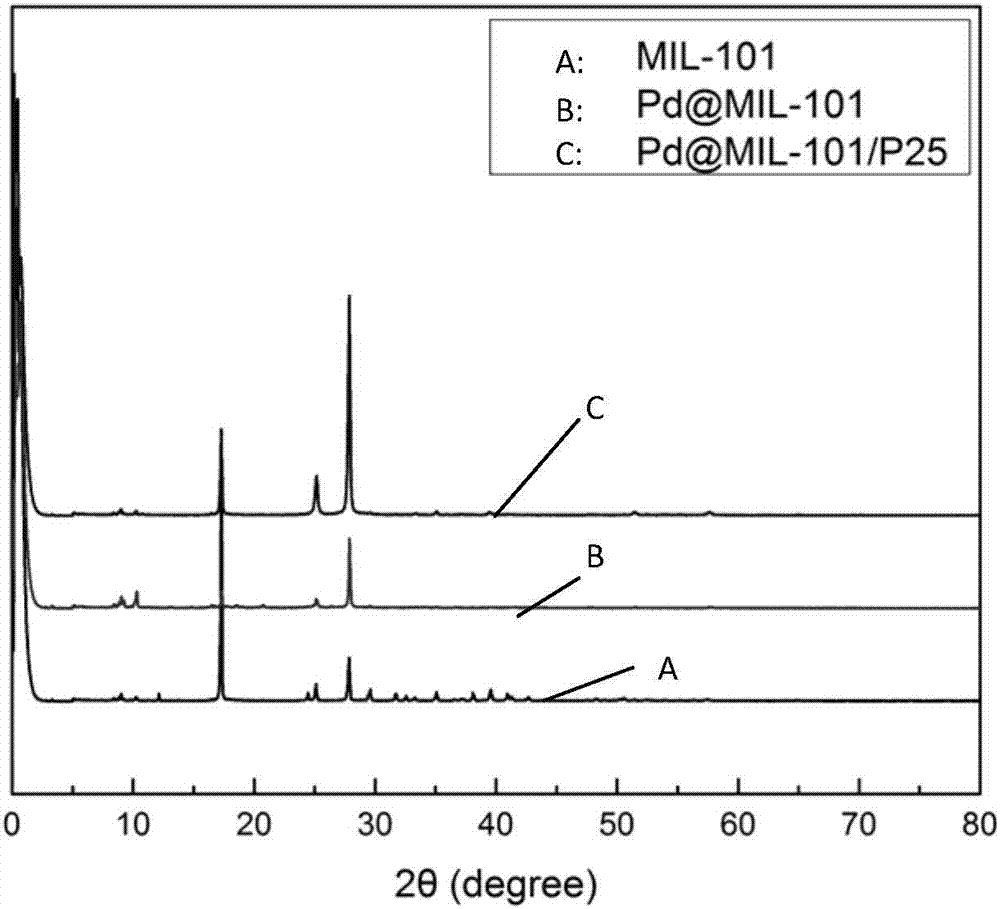

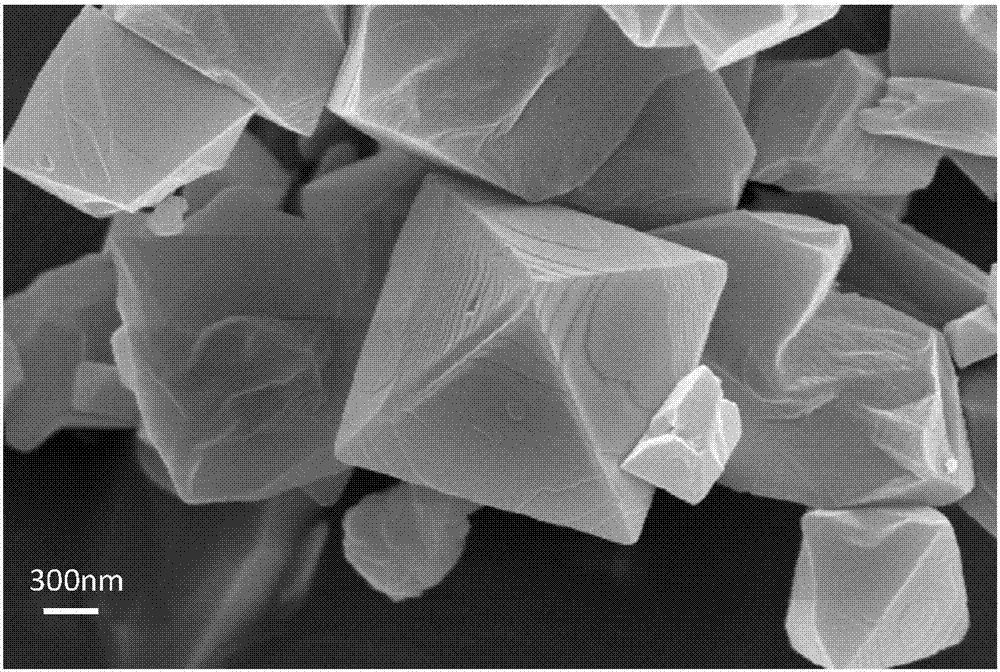

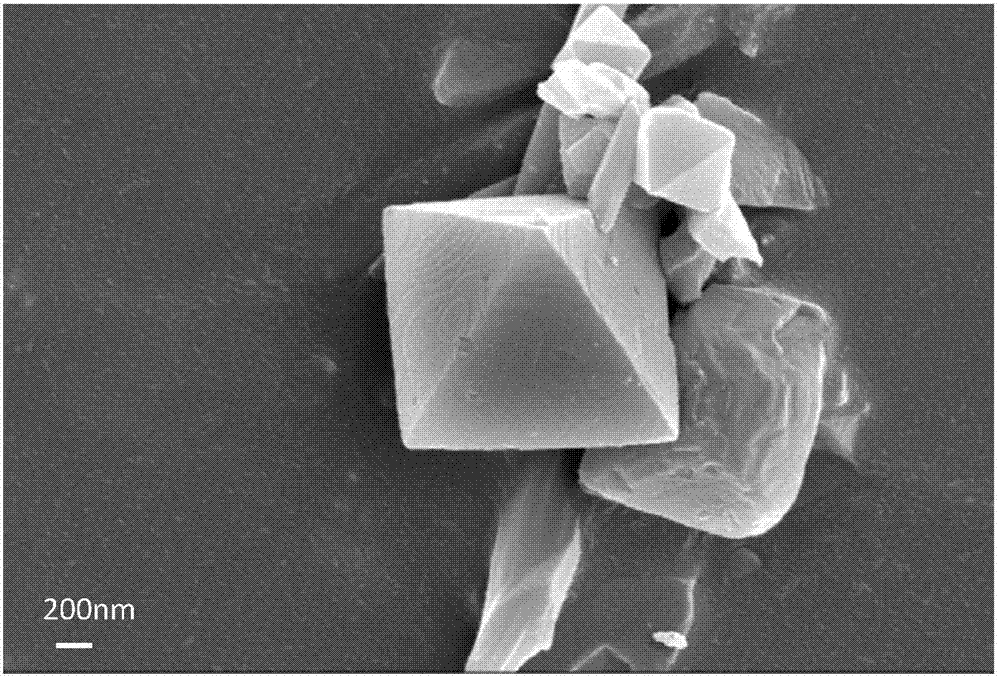

[0038] Pd@MIL-101 / TiO 2 Preparation: Add 0.1g of Pd@MIL-101 to 20mL of deionized water, mix with ultrasonic, stir at room temperature for 30min to obtain solution A, then add 0.003g of TiO 2 Slowly add to the stirring solution A, continue stirring at room temperature for 6 hours, then filter the solution through a 250-mesh stainless steel filter, wash with DMF and deionized water for 3 times, and vacuum-dry at 150°C to obtain Pd @MIL-101 / TiO 2 catalyst of light. XRD patterns of different photocatalysts ( figure 1 ) indicates that noble metals and TiO 2 The load modification did not destroy the structure of MIL-101. From the scanning electron microscope ( Figure 2A ~ Figure 2C ) and transmission electron microscopy ( Figure 3A ~ Figure 3C ) can be seen the existence of an obvious three-layer structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com