Denitrated flue gas sampling and pretreatment device

A pretreatment device and flue gas technology, applied in the direction of sampling device, test sample preparation, etc., to achieve the effects of corrosion prevention, easy air tightness, and simple cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

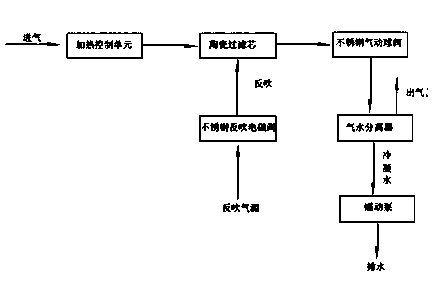

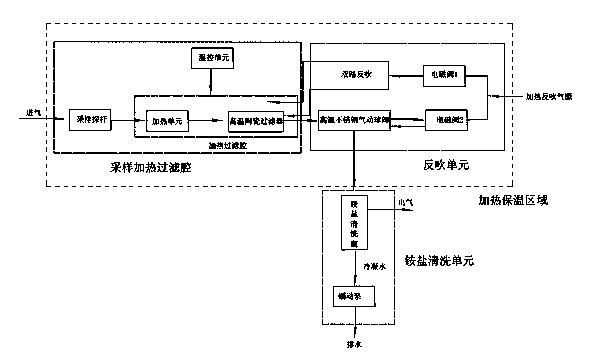

Method used

Image

Examples

Embodiment 1

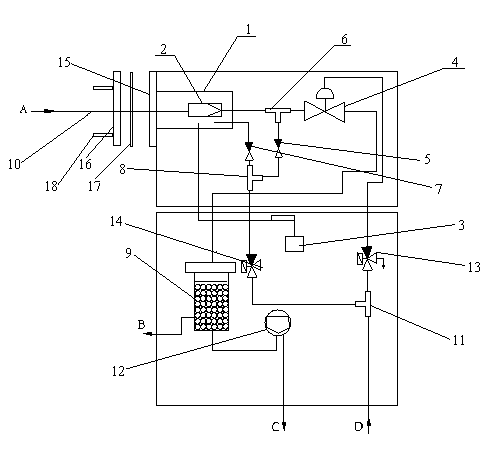

[0028] One end of the sampling probe 10 is connected to the mounting flange 16, and the mounting flange 16 is connected to the mounting flange 15 through 4 stainless steel studs 18; the sealing surface 17 is between the mounting flange 16 and the mounting flange 15, heated The high-temperature ceramic filter 2 of the filter cavity 1 is connected with the air inlet of the first three-way gas joint 6, and one exhaust port of the first three-way gas joint 6 is connected with the first check valve 5, and the other exhaust port is connected with the first check valve 5. The high-temperature stainless steel pneumatic valve 4 is connected, the air outlet of the high-temperature stainless steel pneumatic valve 4 is connected to the ammonium salt cleaning bottle 9 through a pipeline, and the water outlet at the bottom of the ammonium salt cleaning bottle 9 is connected to the peristaltic pump 12; the heating filter chamber 1 is connected to the second check valve 7 connection, the other...

Embodiment 2

[0031] The structure of the device is the same as in Example 1. A temperature alarm unit is added at the probe of the sampling probe. When the heating control unit fails and the temperature is lower than the preset alarm temperature, the alarm function is activated, so that the operating status of the equipment can be understood in time, and the equipment can be prevented from using Ammonium salt crystals block the gas path.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com