Preparation method of molybdenum disulfide coated titanium dioxide hollow core-shell structure composite photocatalyst, and application of photocatalyst

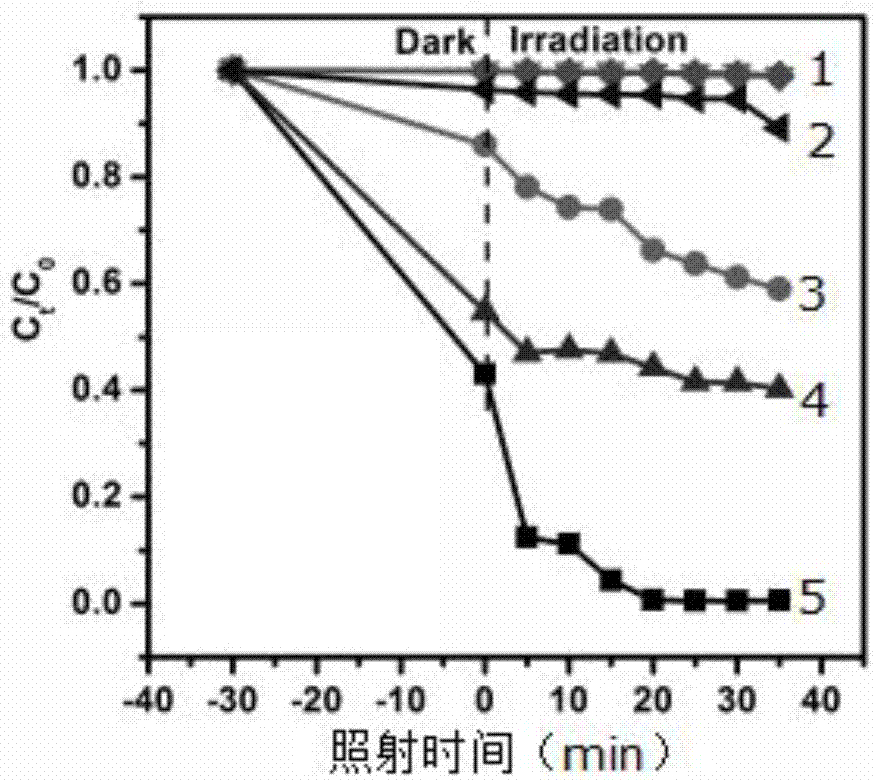

A titanium dioxide and core-shell structure technology is applied to the preparation and application field of a titanium dioxide hollow core-shell structure composite photocatalyst coated with molybdenum disulfide, and can solve the problems of high cost of the composite photocatalyst and poor 4-nitrophenol effect. , to achieve the effect of simple synthesis method and strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: The preparation method of a molybdenum disulfide-coated titanium dioxide hollow core-shell structure composite photocatalyst in this embodiment is specifically carried out according to the following steps:

[0015] 1. SiO 2 Disperse the powder in the mixed solution to obtain a reaction system. After ultrasonic dispersion for 10-20 minutes, add tetrabutyl titanate to the reaction system to obtain a suspension. Stir the suspension in a water bath at a temperature of 40-50°C for 10- 14h, centrifuged, washed and dried to obtain a white solid, and the white solid was calcined at a temperature of 500-600°C for 1h to obtain SiO 2 @TiO 2 ; The mixed solution is dehydrated alcohol and NH 3 ·H 2 Mixture of O, where NH 3 ·H 2 The weight percent of O is 25%~28%; The SiO 2 The mass of the powder and the volume ratio of the mixed solution are 1g:(1200~1400)mL; the SiO 2 The mass ratio of powder to tetrabutyl titanate is 1g:(0.8~1.2)mL;

[0016] Second, the (NH ...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 1, the suspension is stirred for 12 hours in a water bath at a temperature of 45°C. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: in Step 1, the white solid is calcined at a temperature of 550° C. for 1 hour. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com