Adsorbent for removing sulfide in mtbe and its preparation method and application method

An application method and adsorbent technology, which is applied in the improvement field of adsorbent in petrochemical industry, can solve the problems of bad smell of oil products, affecting the stability of oil products, etc., and achieve the effects of not easy to lose, conducive to industrialization promotion, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

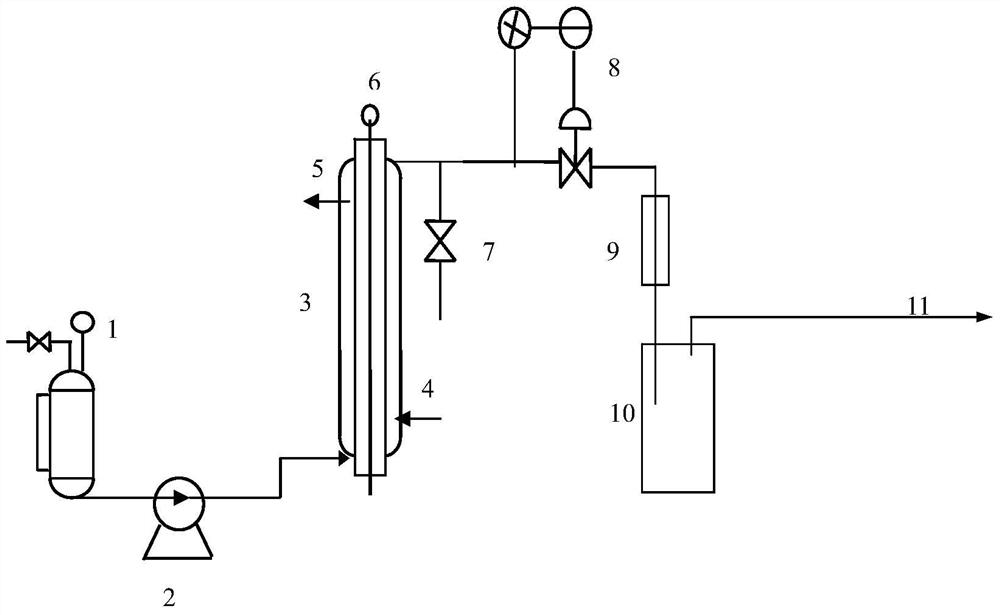

Method used

Image

Examples

Embodiment 1

[0035] Adsorbent A:

[0036] 100g of spherical 13X molecular sieves with a diameter of Baked in a muffle furnace at 450°C for 3h, and then configured with Ag 2 O 2.1g, La 2 o 3 1.5g of impregnating solution was modified, then stood still for 12 hours, then dried at 110°C, and calcined at 450°C for 2h, the obtained adsorbent was the desulfurization adsorbent A loaded with a certain amount of metal active components.

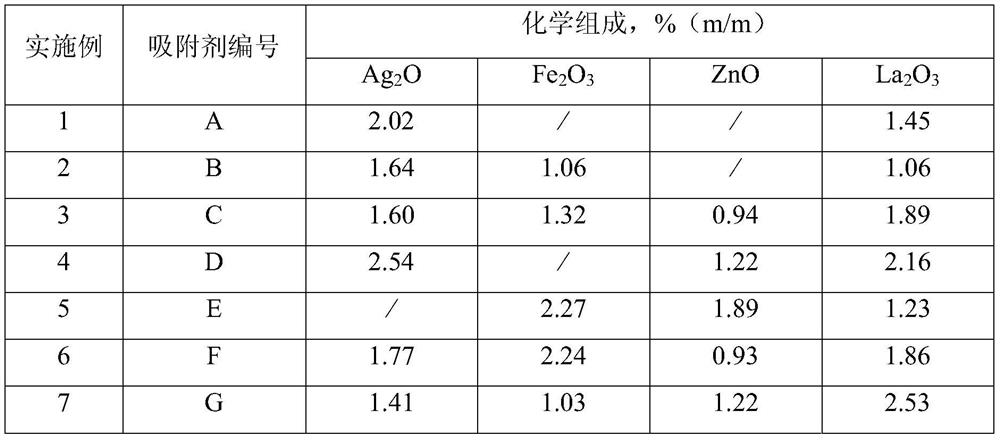

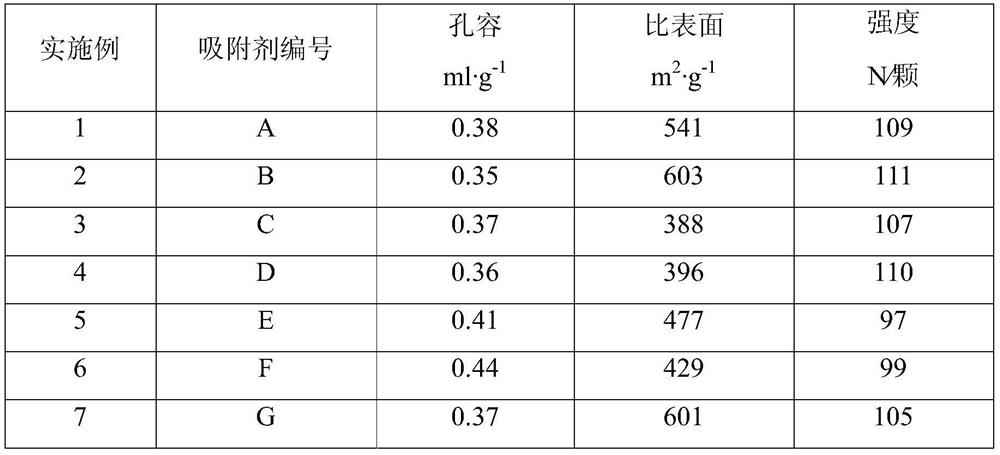

[0037] See Table 1 for details of the mass percentages of the active components and carrier components in the prepared adsorbent, and Table 2 for the physical properties of the adsorbent, such as pore volume, specific surface area and strength.

[0038] Crush the obtained adsorbent A to 20-40 meshes, take 40ml and place it in a Φ25×2.5mm fixed-bed reactor, take methyl tert-butyl ether containing about 30ppm of mixed sulfide, and operate at a temperature of 40°C The pressure is 0.2Mpa, the liquid space velocity (LHSV) is 2h -1 Under certain conditions, throu...

Embodiment 2

[0040] Adsorbent B:

[0041] 100g of spherical 13X molecular sieves with a diameter of Baked in a muffle furnace at 500°C for 4 hours, and then configured Fe-containing 2 o 3 1.1g, Ag 2 O 1.7g, La 2 o 3 1.1g of impregnating solution was modified, then stood still for 12 hours, then dried at 110°C, and calcined at 450°C for 4h, the obtained adsorbent was the desulfurization adsorbent B loaded with a certain amount of metal active components.

[0042] See Table 1 for details of the mass percentages of the active components and carrier components in the prepared adsorbent, and Table 2 for the physical properties of the adsorbent, such as pore volume, specific surface area and strength.

[0043] Crush the obtained adsorbent B to 20-40 meshes, take 40ml and place it in a Φ25×2.5mm fixed-bed reactor, take methyl tert-butyl ether containing about 30ppm of mixed sulfide, and operate at a temperature of 50°C. Pressure 0.5Mpa, liquid space velocity (LHSV) 0.5h -1Under certain ...

Embodiment 3

[0045] Adsorbent C:

[0046] 100g of spherical 13X molecular sieves with a diameter of Baked in a muffle furnace at 500°C for 4 hours, and then configured Fe-containing 2 o 3 1.4g, ZnO 1.0g, Ag 2 O 1.7g, La 2 o 3 2.0g of impregnating solution was modified, then stood still for 12 hours, then dried at 110°C, and calcined at 550°C for 5h, the obtained adsorbent was desulfurization adsorbent C loaded with a certain amount of metal active components.

[0047] See Table 1 for details of the mass percentages of the active components and carrier components in the prepared adsorbent, and Table 2 for the physical properties of the adsorbent, such as pore volume, specific surface area and strength.

[0048] Crush the obtained adsorbent C to 20-40 meshes, take 40ml and place it in a Φ25×2.5mm fixed-bed reactor, take methyl tert-butyl ether containing about 30ppm of mixed sulfide, and operate at a temperature of 40°C Pressure 0.1Mpa, Liquid Space Velocity (LHSV) 2h -1 Under cert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com