A kind of treatment agent for cryopreservation and quick-freezing of Chinese tube whip shrimp and its application

A treatment agent and technology for whip shrimp, applied in the field of deep-freezing and quick-freezing treatment agent for whip shrimp, can solve the problems of inability to inhibit the activity of phenol oxidase, unable to maintain the characteristic color of shrimp, dull appearance of shrimp, etc., and to reduce phenolic Oxidase activity, improved freezing quality, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

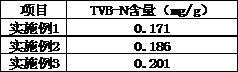

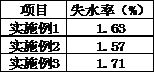

Embodiment 1

[0022] After washing and draining the Chinese tube whip shrimp, soak it in the Chinese tube whip shrimp cryogenic quick-freezing treatment agent at a temperature of 5°C for at least 10 minutes, drain it, and perform liquid nitrogen cryogenic quick-freezing. The Chinese tube whip shrimp and The mass ratio of the freezing treatment agent is 1:5, wherein the deep-freezing and quick-freezing treatment agent for Chinese whip shrimp is composed of the following components in mass percentage: 5% glycerin, 1% carnosol, 0.01% transglutaminase , 1% cysteine, 0.5% betaine, 0.1% arbutin, 0.1% flavanols, 0.1% cuminic acid, 0.5% konjac mannan, the balance is water, cryogenically frozen in liquid nitrogen The process steps are: first reduce the ambient temperature in the liquid nitrogen cabinet to -30°C within 3 minutes, then drop to -65°C within 4 minutes, and finally drop to -90°C within 3 minutes, and maintain the environment at -90°C The temperature continues to quick-freeze the Chinese ...

Embodiment 2

[0024] After washing and draining the Chinese tube whip shrimp, soak it in the Chinese tube whip shrimp cryogenic quick-freezing treatment agent at a temperature of 10°C for at least 10 minutes, drain it, and carry out liquid nitrogen cryogenic quick-freezing. The Chinese tube whip shrimp and The mass ratio of the freezing treatment agent is 1:10, wherein the cryopreservation and quick-freezing treatment agent for Chinese whip shrimp consists of the following components by mass percentage: 10% glycerol, 3% carnosol, 0.03% transglutaminase , 3% cysteine, 1% betaine, 0.3% arbutin, 0.3% flavanols, 0.3% cuminic acid, 1% konjac mannan, the balance is water, cryogenically frozen in liquid nitrogen The process steps are: first reduce the ambient temperature in the liquid nitrogen cabinet to -20°C within 3 minutes, then drop to -60°C within 4 minutes, and finally continue to drop to -80°C within 3 minutes, and maintain the environment at -80°C The temperature continues to quick-freeze...

Embodiment 3

[0026]After washing and draining the Chinese tube whip shrimp, soak it in the Chinese tube whip shrimp cryogenic quick-freezing treatment agent at a temperature of 7°C for at least 10 minutes, drain it, and carry out liquid nitrogen cryogenic quick-freezing. The Chinese tube whip shrimp and The mass ratio of the freezing treatment agent is 1:7, wherein the deep-freezing quick-freezing treatment agent for Chinese whip shrimp consists of the following components by mass percentage: 7% glycerol, 2% carnosol, 0.02% transglutaminase , 2% cysteine, 0.7% betaine, 0.2% arbutin, 0.2% flavanols, 0.2% cuminic acid, 0.7% konjac mannan, the balance is water, cryogenically frozen in liquid nitrogen The process steps are: first reduce the ambient temperature in the liquid nitrogen cabinet to -25°C within 3 minutes, then drop to -63°C within 4 minutes, and finally continue to drop to -85°C within 3 minutes, and maintain the environment at -85°C The temperature continues to quick-freeze the Ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com