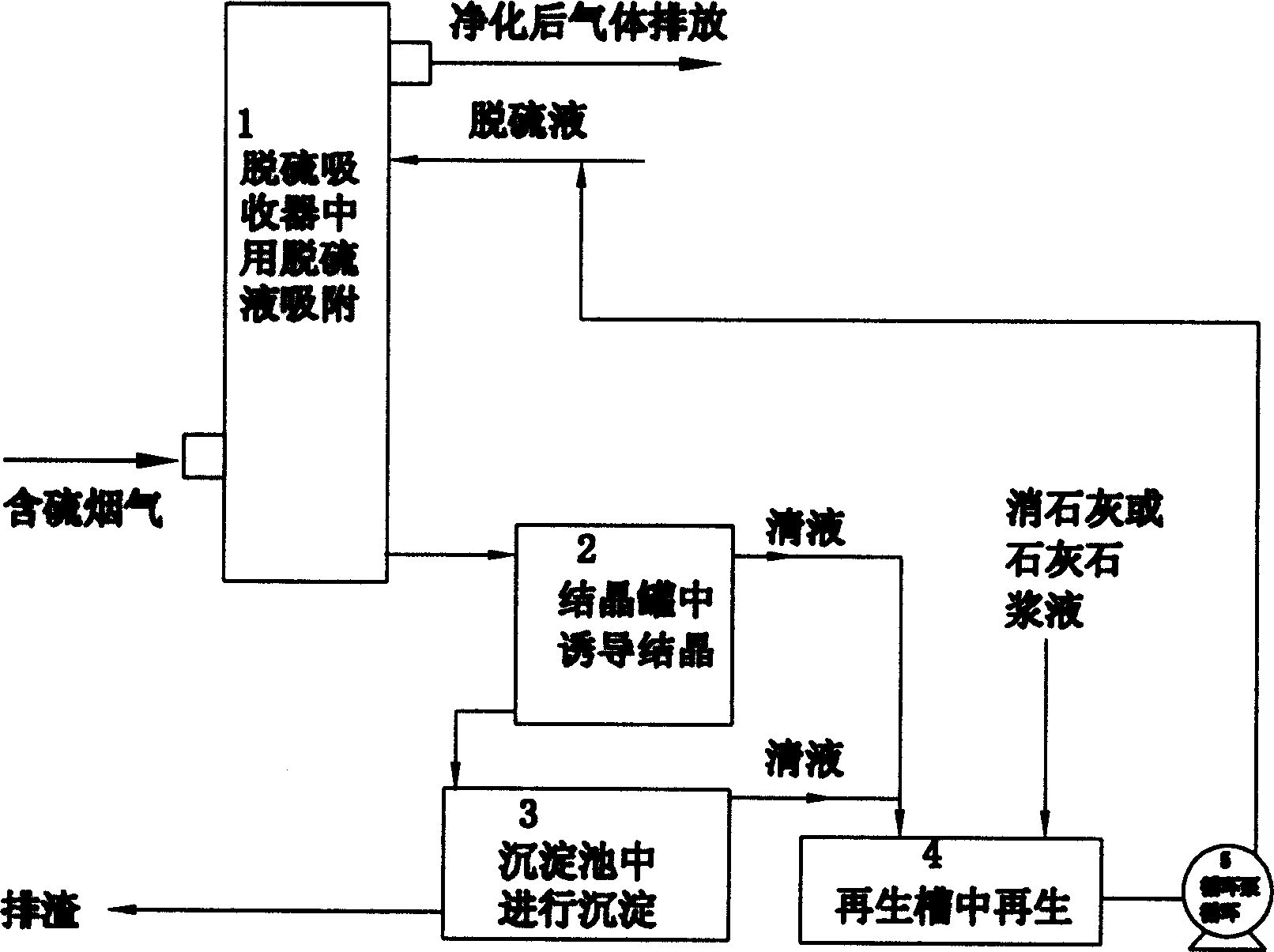

Flue desulfuriznig and dust collecting induction and crystallization process for reuse by concentrated slurry double alkali method

A technology of induced crystallization, desulfurization and dust removal, applied in the environmental field, can solve problems such as desulfurizer and pipeline crystallization blockage sodium salt loss, affecting system energy consumption cycle, etc., to achieve good results, low operating costs, and less water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] At a flue gas temperature of 150°C, the inlet flue gas SO 2 The concentration is 2000mg / m 3 , the pH of the desulfurized liquid entering the desulfurizer (i.e. in the regeneration tank) is 9.0, Na + At a concentration of 0.02 mol / L, Ca + The concentration is 20ppm, and the liquid-gas ratio L / G to the flue gas is 3.0L / m 3 .

[0040] The percentage of the amount of the bottom effluent flowing back to the desulfurization absorber accounts for the total amount of effluent, that is, the reflux ratio is 95%.

[0041] The pH value in the crystallization tank is controlled at 8.0, and the induced seed crystal is an appropriate amount of SiO 2 , CaSO 3 , CaSO 4 mixture.

[0042] After the whole system is in operation, the flue gas desulfurization efficiency reaches 90%.

Embodiment 2

[0044] At a flue gas temperature of 150°C, the inlet flue gas SO 2 The concentration is 2000mg / m 3 , the pH of the desulfurized liquid entering the desulfurizer (i.e. in the regeneration tank) is 8.0, Na + At a concentration of 0.01 mol / L, Ca + The concentration is 20ppm, and the liquid-gas ratio L / G to the flue gas is 3.0L / m 3 , the reflux ratio is 85%.

[0045] The pH value in the crystallization tank is controlled at 7.0, and the induced seed crystal is an appropriate amount of SiO 2 .

[0046] After the whole system is in operation, the flue gas desulfurization efficiency reaches 85%.

Embodiment 3

[0048] At a flue gas temperature of 150°C, the inlet flue gas SO 2 The concentration is 500mg / m 3 , when the flue gas temperature is 120°C, the inlet flue gas SO 2 The concentration is 500mg / m 3 , the pH of the desulfurized liquid entering the desulfurizer is 12.0, Na + At a concentration of 0.4 mol / L, Ca + The concentration is 1000ppm, and the liquid-gas ratio L / G to the flue gas is 15.0L / m 3 , the reflux ratio is 90%.

[0049] The pH value in the crystallization tank is controlled at 10.0, and the induced crystal seed is an appropriate amount of SiO 2 , CaCl 2 , CaSO 3 , CaSO 4 , BaSO 4 mixture.

[0050] After the whole system is in operation, the flue gas desulfurization efficiency reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com