Full-automatic test system and method for gas content of shale

A technology of shale gas content and testing system, applied in the field of automatic shale gas content testing system, can solve the problems of not considering temperature and pressure, affecting testing efficiency, unable to measure multiple groups at the same time, etc., so as to improve testing efficiency and accuracy, Avoid excessive cycle times and avoid the effect of manual intervention in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

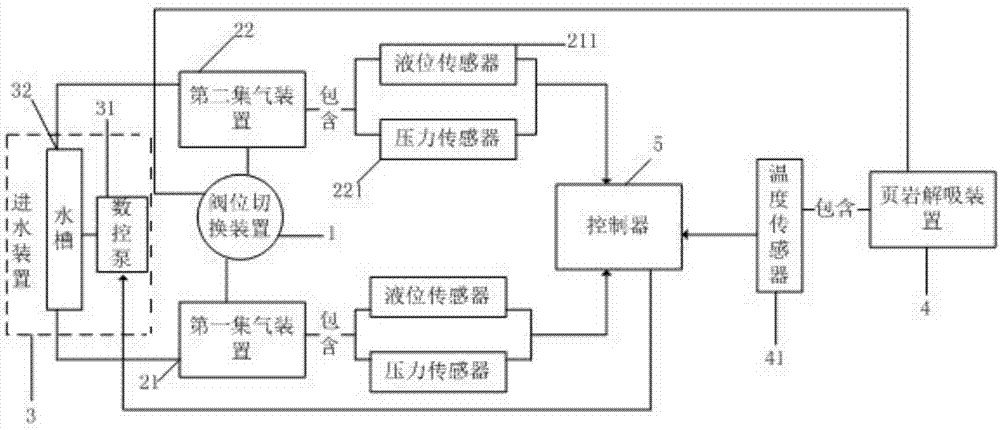

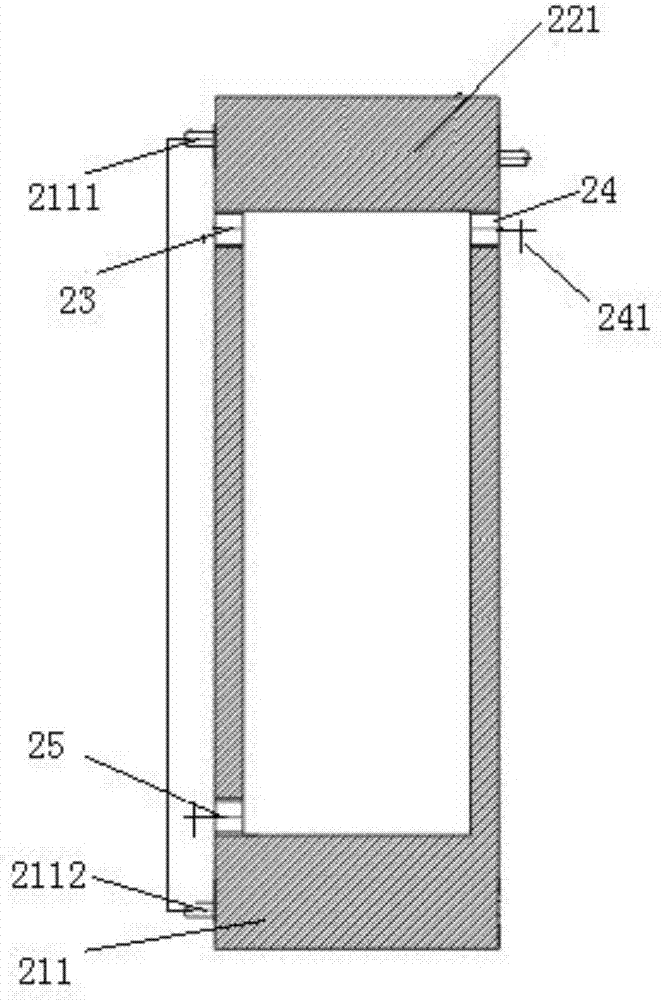

[0060] Please refer to figure 1 , the embodiment of the present invention provides a fully automatic shale gas content testing system, including a first gas collection device 21, a second gas collection device 22, a valve position switching device 1, a water inlet device 3, and a shale desorption device 4 and the controller 5, the first gas collecting device 21 and the second gas collecting device 22 are connected to the valve position switching device 1, and the valve position switching device 1 is connected to the water inlet device 3 and the shale desorption device 4, and the first gas collecting device 21 and the second gas collection device 22 are alternately connected to the water inlet device 3 and the shale desorption device 4 through the valve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com