Preparation method for Tb-Fe-Co ternary rare earth alloy magnetic nano-wire film

A magnetic nano, rare earth alloy technology, applied in nanotechnology, electroforming nanostructure, electrolysis process, etc., can solve the problems affecting the performance of the film, the uneven composition of the nanowire, etc., and achieve the effect of improving the deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The first step, aluminum sheet pretreatment

[0047] Anneal the high-purity aluminum foil with a thickness of 0.3mm and a purity of 99.999% in a protective atmosphere filled with argon or nitrogen to prevent oxidation of the aluminum sheet.

[0048] The annealed aluminum foil is pretreated successively by cleaning, removing the natural oxide film on the surface, and polishing.

[0049] Cleaning: Put the aluminum foil in acetone and absolute ethanol successively, and ultrasonically clean it with a 1000w ultrasonic cleaner for 5 minutes.

[0050] Removing the natural oxide film on the surface: Soak the cleaned aluminum foil in 10%wt NaOH solution for 15min, and then rinse it with deionized water.

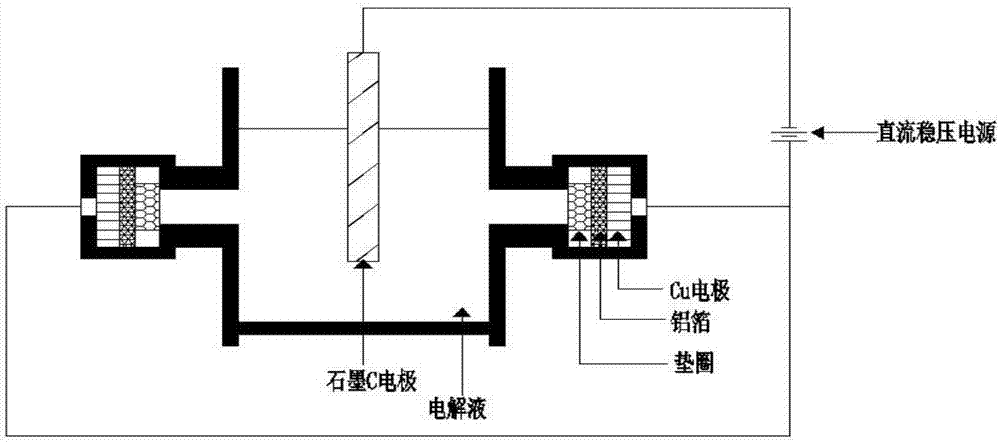

[0051] Polishing treatment: use graphite as the cathode, and aluminum foil from which the natural oxide film has been removed on the surface as the anode, and polish in the polishing solution for 5 minutes with a DC voltage of 15V. The polishing liquid preparation ratio is th...

Embodiment 2

[0075] The first step, aluminum sheet pretreatment

[0076] Anneal high-purity aluminum foil with a thickness of 0.3mm and a purity of 99.999% in a protective atmosphere filled with argon or nitrogen to prevent oxidation of the aluminum sheet.

[0077] The annealed aluminum foil is pretreated successively by cleaning, removing the natural oxide film on the surface, and polishing.

[0078] Cleaning: put the aluminum foil in acetone and absolute ethanol successively, and ultrasonically clean it with a 2000w ultrasonic cleaner for 3 minutes.

[0079] Removing the natural oxide film on the surface: soak the cleaned aluminum foil in 10%wt NaOH solution for 10min, and then rinse it with deionized water.

[0080] Polishing treatment: graphite is used as the cathode, and the aluminum foil from which the natural oxide film on the surface has been removed is used as the anode, and a DC voltage of 13V is used for polishing in the polishing solution for 6 minutes. The polishing liquid p...

Embodiment 3

[0092] The first step, aluminum sheet pretreatment

[0093] Anneal the high-purity aluminum foil with a thickness of 0.3mm and a purity of 99.999% in a protective atmosphere filled with argon or nitrogen to prevent the oxidation of the aluminum sheet.

[0094] The annealed aluminum foil is pretreated successively by cleaning, removing the natural oxide film on the surface, and polishing.

[0095] Cleaning: Put the aluminum foil in acetone and absolute ethanol successively, and clean it with a 1000w ultrasonic cleaner for 7 minutes.

[0096] Removing the natural oxide film on the surface: soak the cleaned aluminum foil in 5%wt NaOH solution for 30min, and then rinse it with deionized water.

[0097] Polishing treatment: graphite is used as the cathode, and the aluminum foil from which the natural oxide film on the surface has been removed is used as the anode, and a DC voltage of 18V is used for polishing in the polishing solution for 3 minutes. The polishing liquid preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com