Stamping type burner of gas stove

A stamping type, burner technology, applied in the direction of gas fuel burners, burners, burners, etc., can solve the problems of high process difficulty, complex structure, large sheet material consumption, etc., to reduce costs, simplify structures, and solve difficult problems The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

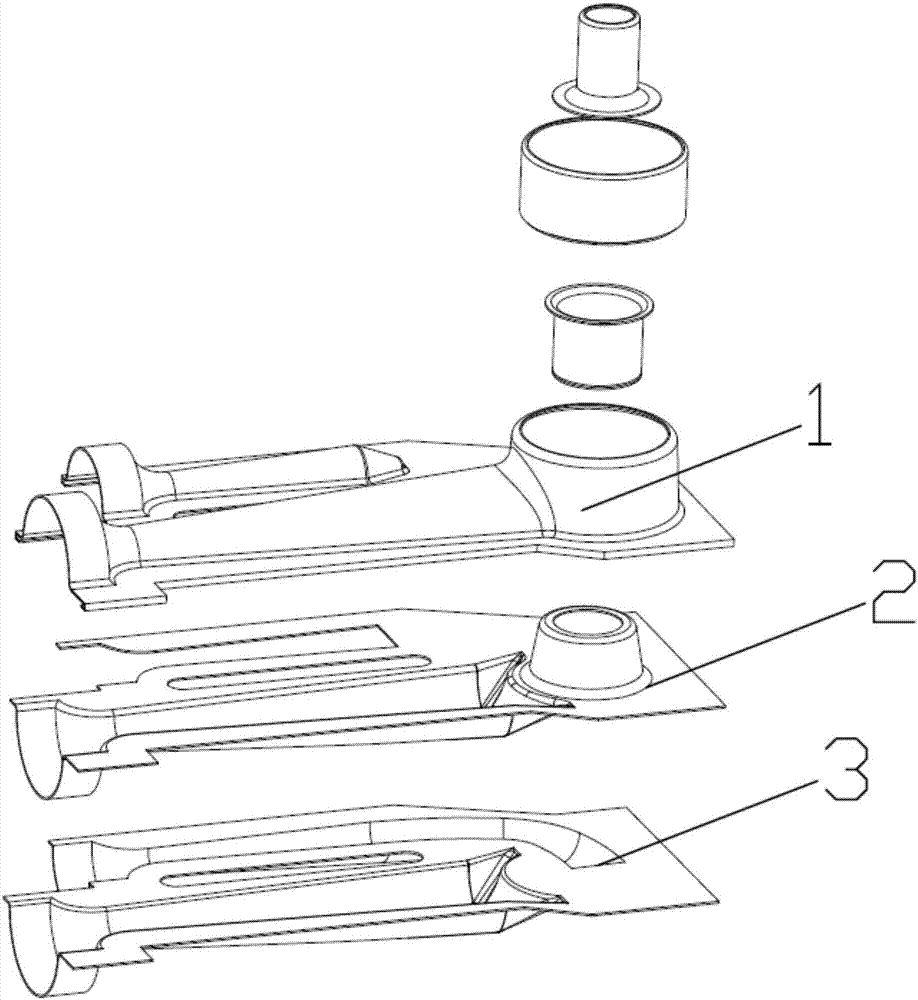

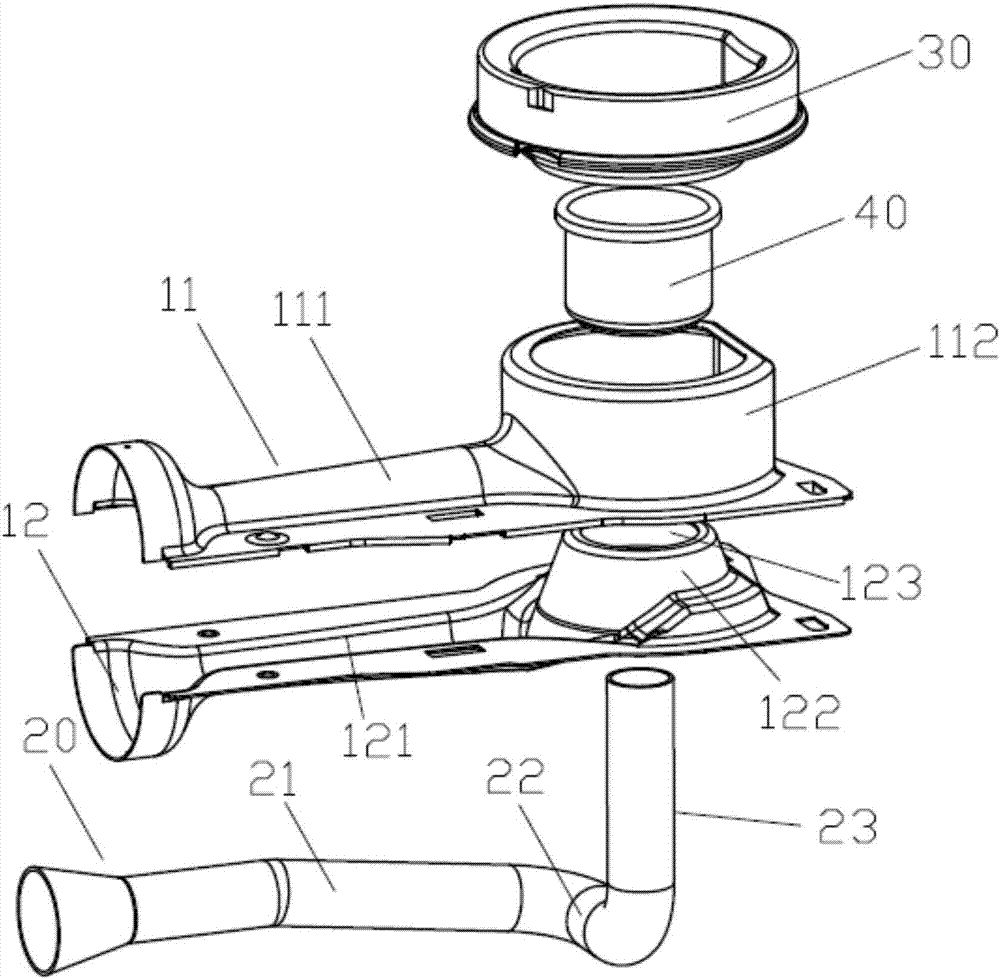

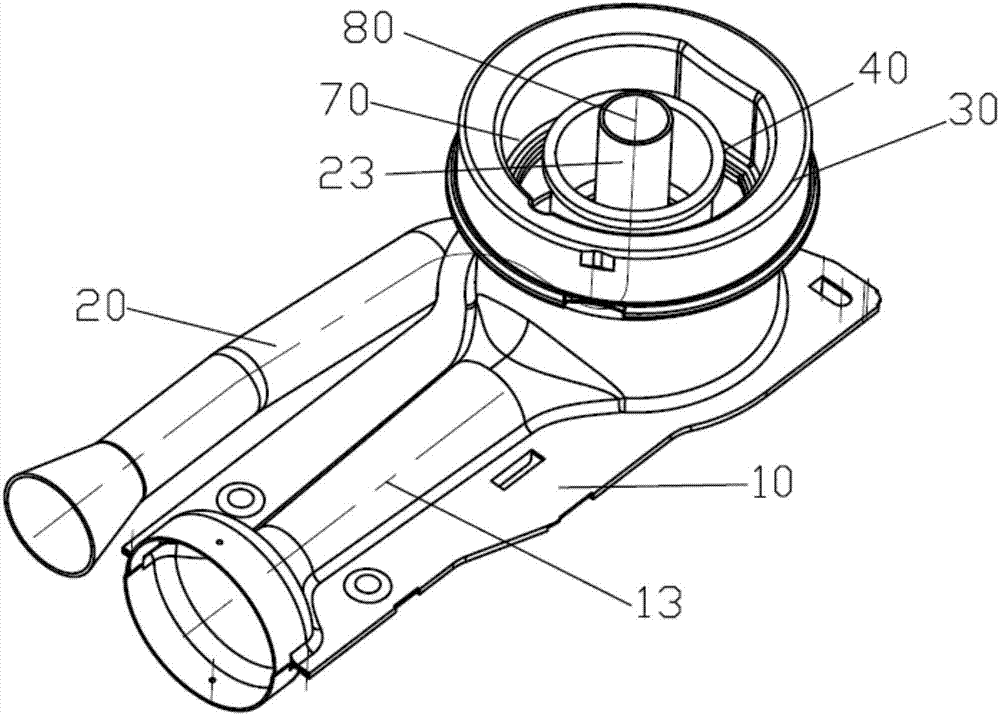

[0023] Example: such as Figure 2-5 As shown, a ram burner of a gas stove includes an outer injection tube 10 and an inner injection tube 20, the outer injection tube 10 includes an upper half tube 11 and a lower half tube 12, and the upper half tube 11 An upper ejection groove 111 and an upper chamber 112 are provided, the two ends of the upper ejection groove 111 are respectively connected to the upper chamber 112 and the gas pipeline, and the lower half pipe 12 is provided with a lower ejection groove 121 and a lower chamber 122 , the lower injection groove corresponds to the upper injection groove, the lower cavity corresponds to the upper cavity, and the upper half pipe 11 and the lower half pipe 12 are fixedly connected together by pressure riveting, when the upper half When the pipe 11 and the lower half pipe 12 are fastened together, the upper ejection groove and the lower ejection groove are combined to form the ejection pipe 13 of the outer ejection pipe 10, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com