Method for making low-temperature refined pickled lard oil

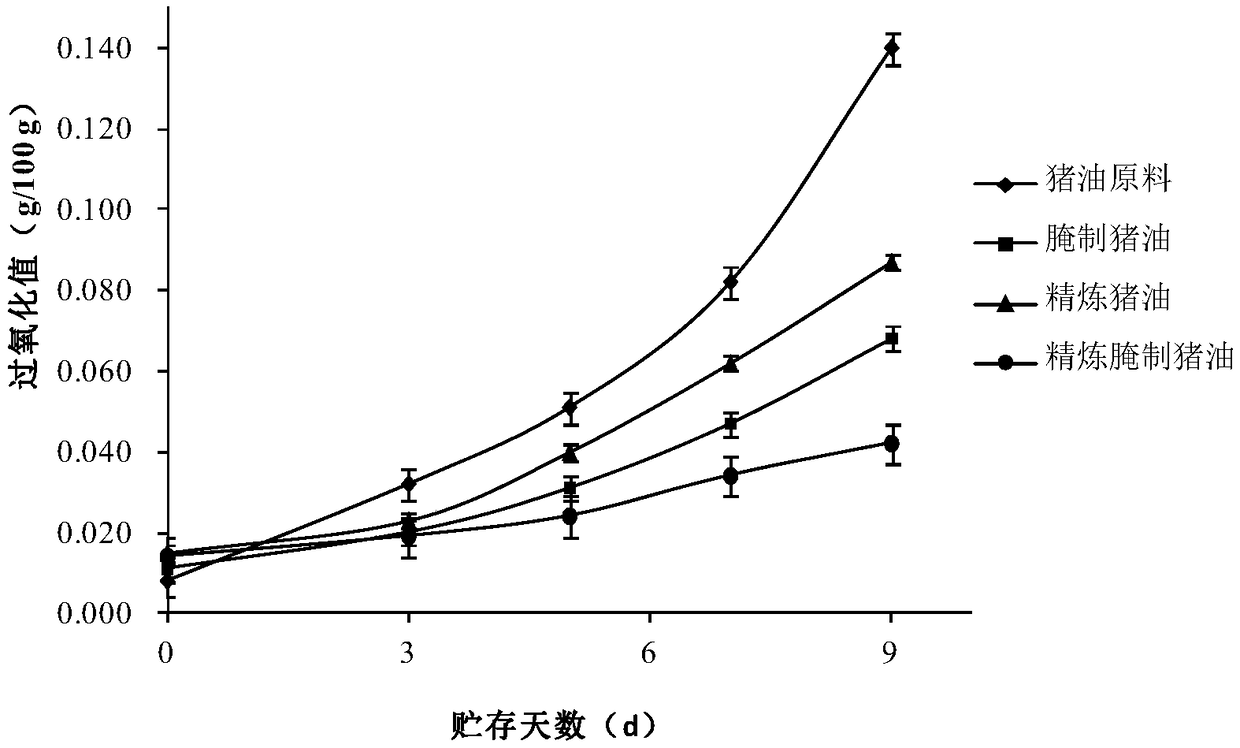

A technology of low-temperature refining and production method, which is applied in the field of lard technology, can solve the problems of reducing the acid value and peroxide value of pickled lard products, prolonging the shelf life of lard, and easily deteriorating lard oil, so as to improve the water removal efficiency. , good flavor and taste, the effect of improving oil production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method for low-temperature refining pickled lard, comprising the steps of:

[0045] Step 1, raw material selection:

[0046] The raw material of lard is frozen lard or fresh lard, using fresh, clean and intact adipose tissue of healthy pigs;

[0047] Step 2, trimming and cleaning:

[0048] Remove the muscle, blood, bones, organs and other fragments adhering to it, wash away the dirt, and get clean lard raw materials;

[0049] Step 3, cut into pieces:

[0050] Cut the raw lard into chunks with a relatively uniform shape, and marinate them evenly;

[0051] Step 4, marinate:

[0052] Spread edible salt evenly on the surface of the lard raw material block, and then place it in a light-proof airtight container to marinate;

[0053] Step 5, vacuum refining:

[0054] Place the marinated lard raw material block in a pressure vessel, add liquid lard to form a solid-liquid mixture; then seal it and vacuumize it, carry out steam heating, and release the pressur...

Embodiment 2

[0069] A preparation method for low-temperature refining pickled lard, comprising the steps of:

[0070] Step 1, raw material selection:

[0071] The raw material of lard is frozen lard or fresh lard, using fresh, clean and intact adipose tissue of healthy pigs;

[0072] Step 2, trimming and cleaning:

[0073] Remove the muscle, blood, bones, organs and other fragments adhering to it, wash away the dirt, and get clean lard raw materials;

[0074] Step 3, cut into pieces:

[0075] Cut the raw lard into chunks with a relatively uniform shape, and marinate them evenly;

[0076] Step 4, marinate:

[0077] Spread edible salt evenly on the surface of the lard raw material block, and then place it in a light-proof airtight container to marinate;

[0078] Step 5, vacuum refining:

[0079] Place the marinated lard raw material block in a pressure vessel, add liquid lard to form a solid-liquid mixture; then seal it and vacuumize it, carry out steam heating, and release the pressur...

Embodiment 3

[0094] A preparation method for low-temperature refining pickled lard, comprising the steps of:

[0095] Step 1, raw material selection:

[0096] The raw material of lard is frozen lard or fresh lard, using fresh, clean and intact adipose tissue of healthy pigs;

[0097] Step 2, trimming and cleaning:

[0098] Remove the muscle, blood, bones, organs and other fragments adhering to it, wash away the dirt, and get clean lard raw materials;

[0099] Step 3, cut into pieces:

[0100] Cut the raw lard into chunks with a relatively uniform shape, and marinate them evenly;

[0101] Step 4, marinate:

[0102] Spread edible salt evenly on the surface of the lard raw material block, and then place it in a light-proof airtight container to marinate;

[0103] Step 5, vacuum refining:

[0104] Place the marinated lard raw material block in a pressure vessel, add liquid lard to form a solid-liquid mixture; then seal it and vacuumize it, carry out steam heating, and release the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com