A kind of lubricating oil containing perfluorooctanesulfonyl fluoride and its preparation method

A technology of perfluorooctanesulfonyl fluoride and fluorooctanesulfonyl fluoride, which is applied in the field of lubricating oil containing perfluorooctanesulfonyl fluoride and its preparation, can solve the problems of poor anti-wear and anti-friction performance of lubricating oil, etc. Achieve the effects of improving anti-gluing ability, enhancing load-bearing performance, and enhancing anti-wear and anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

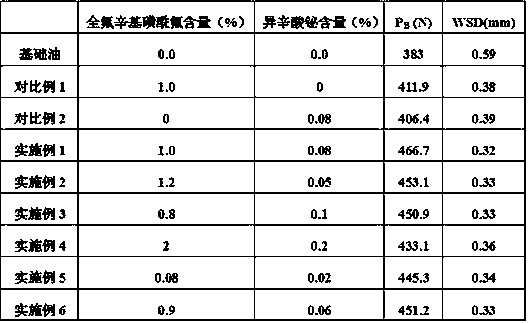

Embodiment 1

[0016] Add 1% perfluorooctane sulfonyl fluoride to the base oil and mix well at 80-90°C; then cool down to 40-50°C, add 0.08% bismuth isooctanoate and mix well .

Embodiment 2

[0018] Add 1.2% perfluorooctane sulfonyl fluoride to the base oil and mix well at 80-90°C; then cool down to 40-50°C, add 0.05% bismuth isooctanoate and mix evenly .

Embodiment 3

[0020] Add 0.8% perfluorooctane sulfonyl fluoride to the base oil and mix evenly at 80-90°C; then cool down to 40-50°C, add 0.1% bismuth isooctanoate and mix evenly .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com