Device for treating catering oil-water with ionized oxygen

A technology of ionic oxygen and catering, applied in filtration treatment, grease/oily substance/suspton removal device, multi-stage water treatment, etc., to achieve the effects of eliminating pollution, efficient and thorough decomposition, and increasing reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

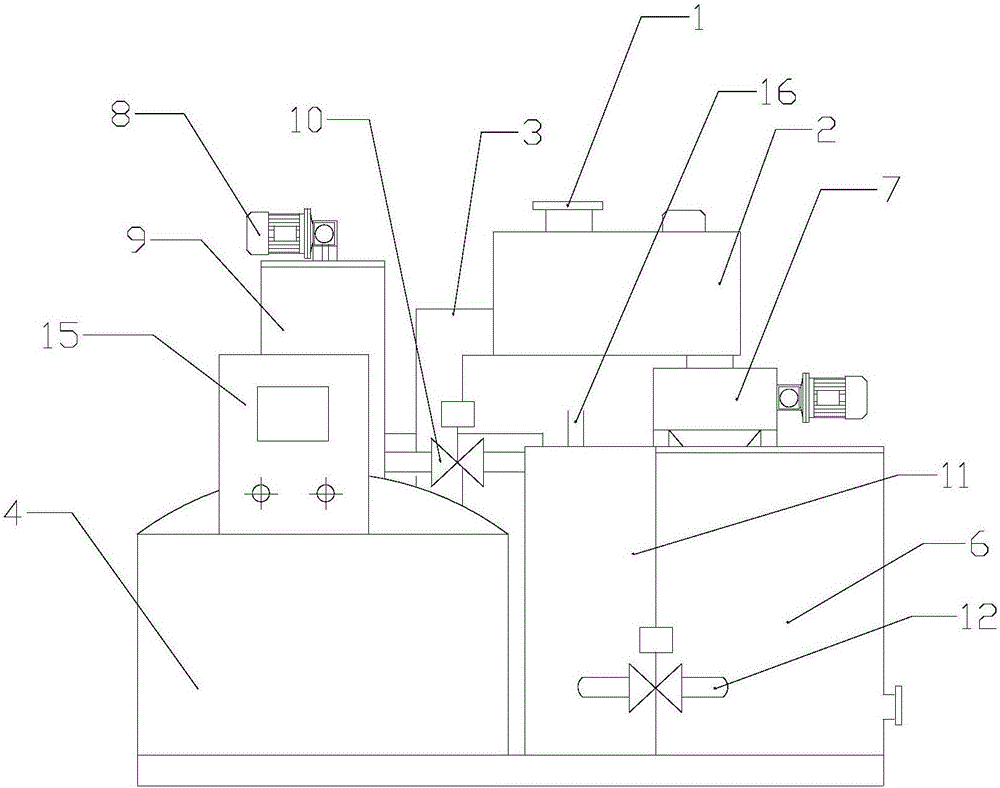

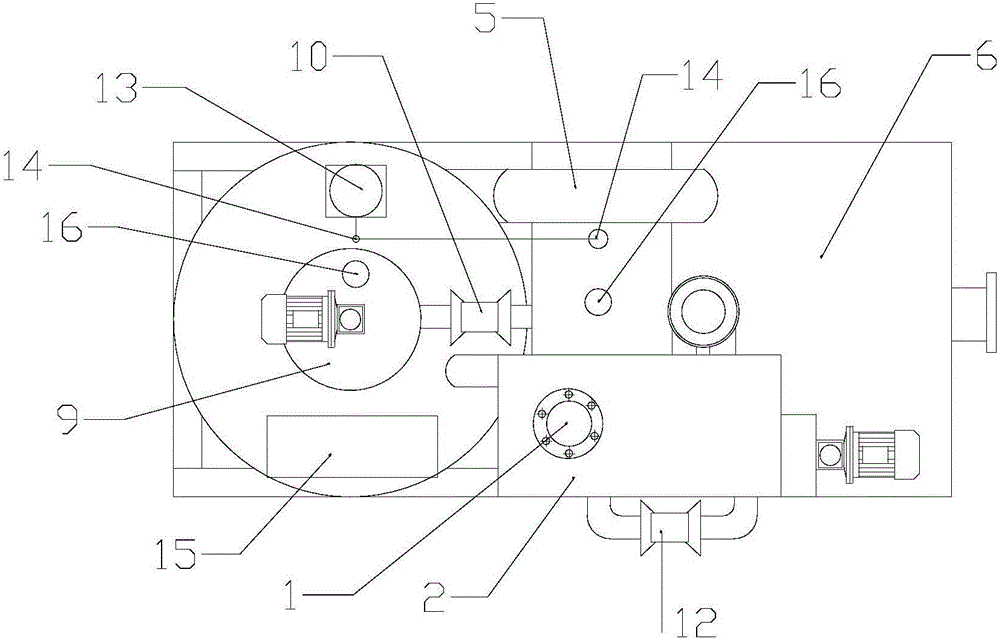

[0028] This embodiment discloses a device for treating catering oil and water with ion oxygen, including a water inlet pipe 1, a slag remover 2, a bypass pipe 3, an oil-water separation box 4, a bypass pipe 5, a sewage collection box 6, and a grinder 7 , mixer 8, oil collection area 9, oil discharge valve 10, oil biochemical box 11, bypass valve 12, ion oxygen generator 13, ventilation pipe 14, control box 15, ventilation pipe 16.

[0029] Catering waste water enters the deslagging machine 2 from the water inlet pipe 1, and after the solid residue is intercepted by the deslagging machine, the oily waste water enters the oil-water separation tank 4 through the bypass pipe 3, and the ionized oxygen is input through the ion oxygen generator 13 to effectively separate and decompose the grease. The decomposed grease floats upwards and enters the grease collection area 9, and the sewage after the grease is separated enters the sewage collection tank 6 through the bypass pipe 5 and is...

Embodiment 2

[0032] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment.

[0033]As preferably, the material used in the oil-water separation box 4, the grease collection area 9 and the grease biochemical box 11 is austenitic stainless steel or nickel-titanium alloy, which can effectively prevent the substrate from being corroded by organic matter, acidic substances, alkaline substances, oxygen ions, etc. It has excellent corrosion resistance, is not easy to deposit dirt, and is easy to clean. There is a ventilation pipe on the top of the grease collection area and the grease biochemical box, which supplies air to the drainage system to make the water flow in the pipeline unimpeded, reduce the range of air pressure changes in the drainage pipeline, and discharge the harmful gas emitted in the indoor drainage pipeline to the outside, reducing the air pressure in the drainage pipeline. Risk of pipe corrosi...

Embodiment 3

[0035] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment.

[0036] As a preference, the sewage collection box 6 is connected to the sewage pipeline through a water pipe, and the sewage in the sewage collection box 6 is discharged naturally or lifted by a water pump, and the treated sewage can be discharged in time without breeding harmful bacteria. If the installation height of the equipment is higher than that of the sewage pipe, higher than 0.5m, natural discharge can be used; if the equipment is installed horizontally or the height is not higher than 0.5m, it is recommended to use the pump to lift the installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com