Clean production process for treating soluble organic solid wastes by renewable targeted adsorption

An organic solid and adsorption treatment technology, applied in the field of processing production solid waste and soluble organic solid waste, can solve the problems of secondary pollution, high environmental protection treatment cost, complicated process, etc. The effect of cleaning and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

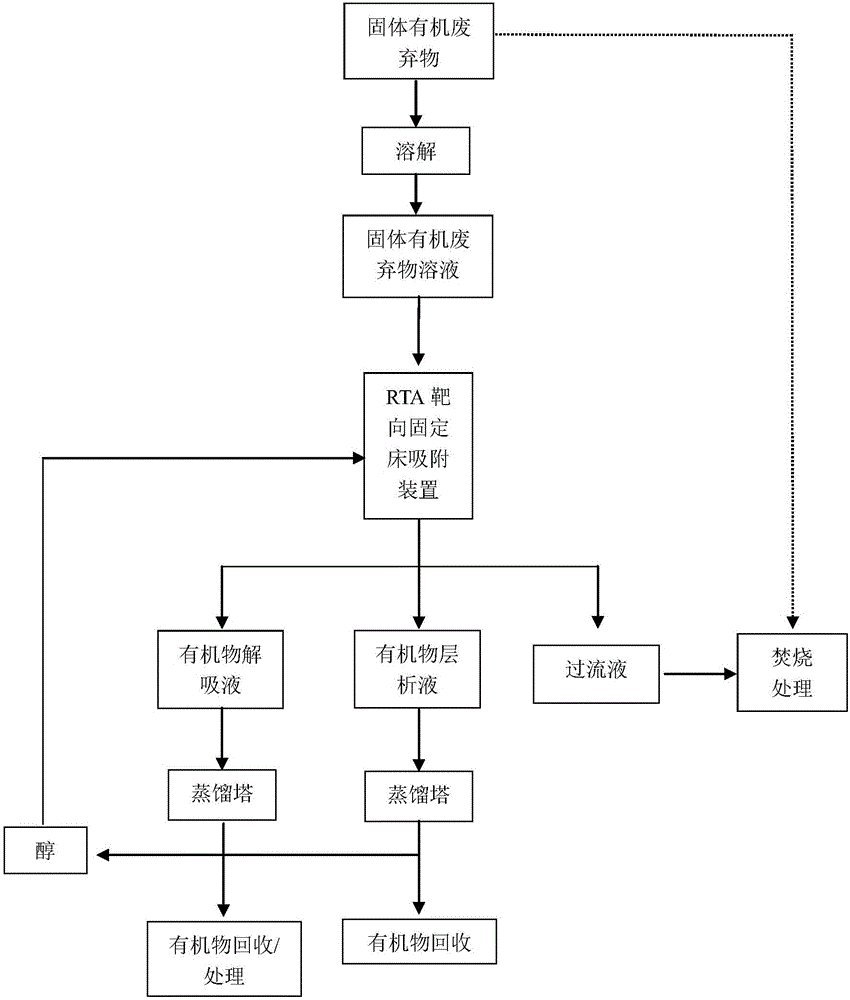

Image

Examples

Embodiment 1

[0032] In this example, a clean production process of regenerable targeted adsorption treatment of soluble organic solid waste is applied to the clean production process of soluble phthalic anhydride solid waste, including the following steps:

[0033] (1) Organic solid waste is produced in the production process of phthalic anhydride by oxidation of o-xylene, dissolved in 15% ethanol, and the high-concentration organic solid waste solution containing phthalic anhydride and benzoic acid is sent into a renewable targeted adsorption fixed bed The device performs targeted adsorption;

[0034] (2) Send the waste liquid flowing down after being adsorbed by the renewable targeted adsorption fixed bed device into the distillation tower, and the gas phase is condensed to obtain ethanol, and return to step (1) for recycling. The still residue (does not contain phthalic anhydride and benzoic acid, only High combustion value organic matter soluble in ethanol) is sent to the incineration ...

Embodiment 2

[0042] The steps of a clean production process for regenerable targeted adsorption treatment of soluble organic solid waste described in this example are the same as those in Example 1, with the difference that ethanol is regenerated with a hydrochloric acid solution with a mass fraction of 1.9% The final regenerable targeted adsorption device is forced to regenerate.

Embodiment 3

[0044]In this example, a clean production process for treating soluble organic solid waste by renewable targeted adsorption is applied to clean production for treating soluble salicylonitrile solid waste, including the following steps:

[0045] (1) Adopt salicylic acid, urea, sulfamic acid and catalyst (for magnesia and cyanuric chloride) to produce organic solid waste in the production process of salicylonitrile, be dissolved in toluene, will contain salicylonitrile, salicylic nitrile The high-concentration organic solid waste solution of amides and impurities (a small amount of urea, sulfamic acid, phenol, magnesium oxide and cyanuric chloride) is sent to a regenerative targeted adsorption fixed bed device for targeted adsorption;

[0046] (2) Send the waste liquid that flows down after being adsorbed by the renewable targeted adsorption fixed bed device into the distillation tower, and the gas phase is condensed to obtain toluene, and return to step (1) for recycling, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com