Sioc composite electrode material

A technology of composite materials and particles, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as insufficient electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] Preparation of SiOC composites according to the invention

[0139] A sample of 28.850 g of amorphous phenyl bridged polysilsesquioxane compound and 6.053 g of crystalline silicon was put together in a roller and ground at 150 rpm for 1 hour.

[0140] The resulting powder was then pyrolyzed at 1000 °C for 1 hour under an argon atmosphere.

[0141] After pyrolysis, the samples were recovered and milled at 400 rpm for 30 minutes.

[0142] The obtained powder was added to an aqueous solution (62.5 g / L) containing PVA dissolved at 60°C. The resulting mixture was spray dried at 100°C, and the powder was recovered.

[0143] The powder was heat-treated at 200°C for 16 hours in air, and then pyrolyzed at 1000°C for 1 hour under an argon atmosphere.

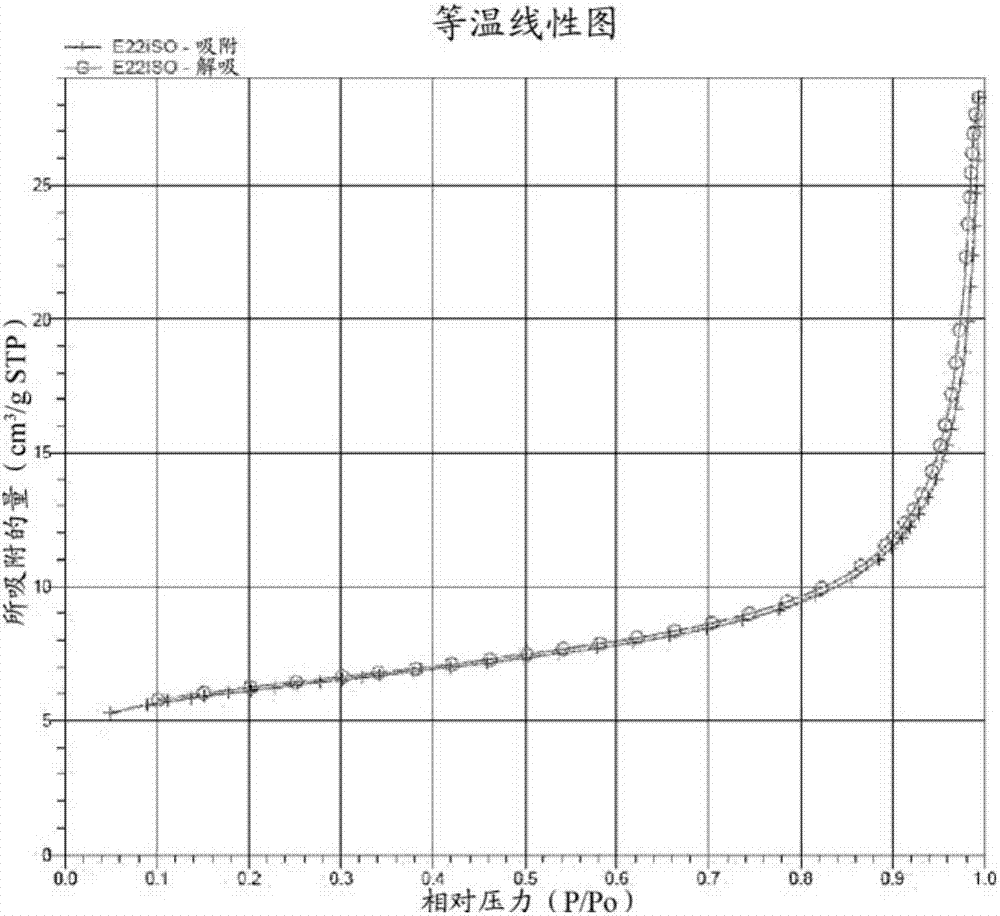

[0144] Analysis of the obtained powder

[0145] Elemental analysis

[0146] The silicon content of the powder obtained was measured by inductively coupled plasma (ICP) emission spectroscopy. After combustion in a high-freq...

Embodiment 2

[0158] Embodiment 2 (comparative embodiment)

[0159] A 10 g sample of the phenyl bridged polysilsesquioxane compound was pyrolyzed at 1000° C. for 1 hour under an argon atmosphere.

[0160] The recovered samples were then milled at 400 rpm for 5 minutes.

[0161] The obtained powder was added to an aqueous solution containing dissolved PVA (62.5 g / L) and dispersed crystalline silicon particles (27.4 g / L).

[0162] The mixture was spray dried at 100°C and the powder was recovered.

[0163] The powder was heat-treated at 200°C for 16 hours in air, and then pyrolyzed at 1000°C for 1 hour under an argon atmosphere.

Embodiment 3

[0165] Preparation of SiOC composites according to the invention

[0166] A sample of 28.850 g of amorphous phenyl bridged polysilsesquioxane compound and 6.053 g of crystalline silicon was put together in a roller and ground at 150 rpm for 1 hour.

[0167] The obtained powder was then pyrolyzed at 1000 °C for 1 hour under an argon atmosphere.

[0168] After pyrolysis, the samples were recovered and milled at 400 rpm for 30 min.

[0169] A 6.25 g dosage of solid PVA was added to the roll and the mixture was ground at 150 rpm for 1 hour. The powder is recycled.

[0170] The powder was heat-treated at 200°C for 16 hours in air, and then pyrolyzed at 1000°C for 1 hour under an argon atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com