Interior wall coating and preparation method thereof

A technology for interior wall coatings and raw materials, applied in the direction of coatings, etc., can solve the problems of inconspicuous improvement of the indoor environment, and achieve the effects of excellent thermal insulation and sound insulation, low cost, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

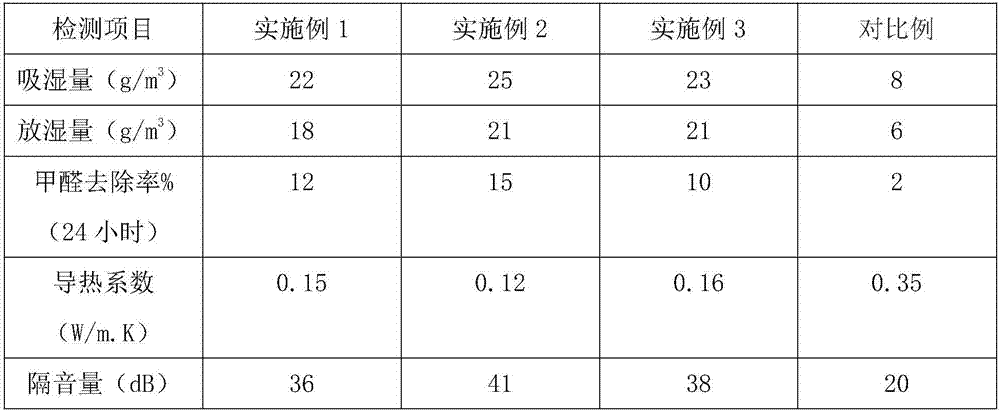

Examples

Embodiment 1

[0027] An interior wall coating, the following raw materials are weighed: 30kg of acrylic resin, 20kg of silicone acrylic resin, 15kg of modified nano-bamboo charcoal powder, 3kg of barium ice feldspar powder, 5kg of talcum powder, 8kg of styrene-acrylic emulsion, 4kg of diatomaceous earth, and lime calcium powder 1kg, defoamer 1kg, wetting and dispersing agent 2kg, film-forming aid 2kg, leveling agent 1kg and organic solvent 15kg;

[0028] The preparation method of the above-mentioned modified nano-bamboo charcoal powder is: take 15kg of bamboo charcoal powder and put it into glacial acetic acid solution and soak it for 3 hours, take it out, filter it, wash it with deionized water, then calcinate it at 360°C for 1 hour, and then grind it into a nano-powder. .

[0029] Among them, the above-mentioned defoaming agent adopts polydimethylsiloxane; the wetting and dispersing agent adopts calcium lignosulfonate; Two mixtures of isobutyrate, and the mass ratio between the two is 1:...

Embodiment 2

[0035] An interior wall coating, the following raw materials are taken by weighing: 40kg of acrylic resin, 30kg of silicone acrylic resin, 20kg of modified nano-bamboo charcoal powder, 6kg of barium ice feldspar powder, 10kg of talcum powder, 15kg of styrene-acrylic emulsion, 8kg of diatomaceous earth, lime calcium powder 5kg, defoamer 2kg, wetting and dispersing agent 3kg, film-forming aid 3kg, leveling agent 2kg and organic solvent 25kg;

[0036] The preparation method of the above-mentioned modified nano-bamboo charcoal powder is: take 20 kg of bamboo charcoal powder and put it into glacial acetic acid solution to soak for 4 hours, take it out, filter, wash with deionized water, then calcinate at 390 ° C for 1.5 hours, and then grind it into a nano-powder. have to.

[0037] Among them, the above-mentioned defoaming agent adopts phenylethyl alcohol oleate; the wetting and dispersing agent adopts alkyl aryl polyether; Two mixtures of butyrate, and the mass ratio between the ...

Embodiment 3

[0043] An interior wall coating, the following raw materials are taken by weighing: 50kg of acrylic resin, 40kg of silicone acrylic resin, 25kg of modified nano-bamboo charcoal powder, 10kg of barium ice feldspar powder, 16kg of talcum powder, 22kg of styrene-acrylic emulsion, 12kg of diatomaceous earth, lime calcium powder 10kg, defoamer 5kg, wetting and dispersing agent 6kg, film-forming aid 6kg, leveling agent 5kg and organic solvent 35kg;

[0044] The preparation method of the above-mentioned modified nano-bamboo charcoal powder is: take 25kg of bamboo charcoal powder and put it into glacial acetic acid solution and soak it for 5h, take it out, filter it, wash it with deionized water, calcinate it at 420°C for 2h, and then grind it into a nano-powder. .

[0045] Among them, the above-mentioned defoaming agent adopts polyoxypropylene; the wetting and dispersing agent adopts diisooctyl hyaluronate; Two mixtures of diisobutyrate, and the mass ratio between the two is 1:3; ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com