Method for preparing graphene with solid phase assisted microwaves

A graphene and microwave technology, applied in the field of materials science, can solve the problems of polluting the environment, high energy consumption, complex reduction process, etc., and achieve the effects of high reduction degree, simplified process, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Utilize improved Hummers method to prepare the mixed solution of graphite oxide and water, concrete steps are as follows:

[0024] Measure 96mL of concentrated sulfuric acid and place it in a dry container, add 2g of sodium nitrate to it, stir to dissolve the sodium nitrate, then add 2g of flake graphite, after the flake graphite is evenly dispersed, slowly add 12g of potassium permanganate, react for 1.45h, During the whole process, an ice bath was used to keep the system at 0-3°C, then the temperature was raised to 35°C for 2 hours, then 80 mL of deionized water was slowly added to the reaction system, the temperature was raised to 95°C for 30 minutes, and then 200 mL of deionized water was slowly added to the reaction system. deionized water, followed by 10 mL H 2 o 2 , continue to react for 10min, the resulting reaction solution is centrifuged, and the gained precipitate is washed with 1000mL mass percentage concentration of 5% HCl aqueous solution to remove metal ...

Embodiment 2

[0026] A method for preparing graphene by solid-phase assisted microwave reduction of graphene oxide, specifically comprising the steps of:

[0027] (1) Sonicate the mixture of graphite oxide and water to 1L, 80W, 40KHz for 45min, centrifuge the suspension obtained after sonication at 2000rpm for 60min, take the supernatant and dry it in a vacuum oven at 80°C for 24h before grinding. Obtain graphene oxide powder;

[0028] The mixed solution of described graphite oxide and water is prepared by an improved Hummers method;

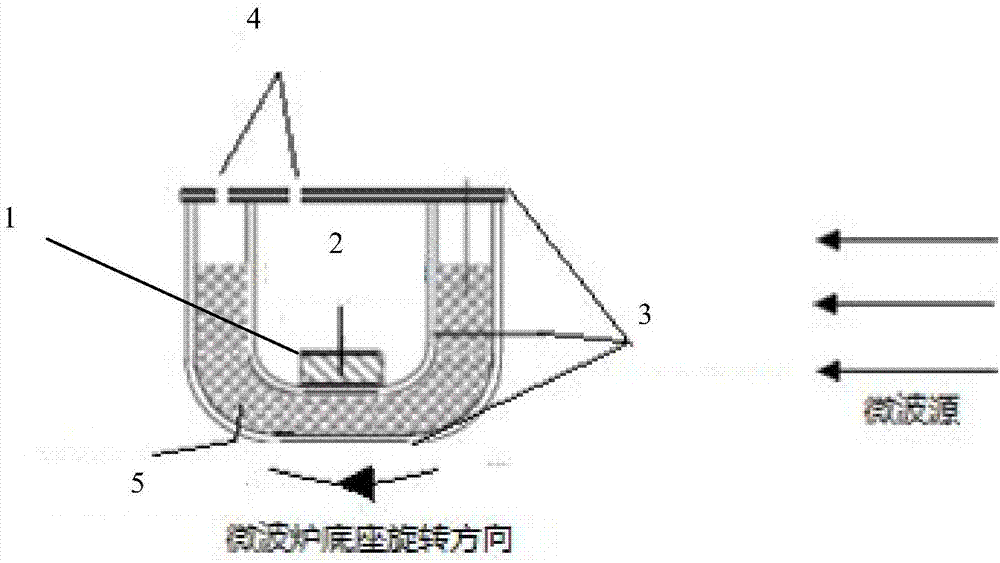

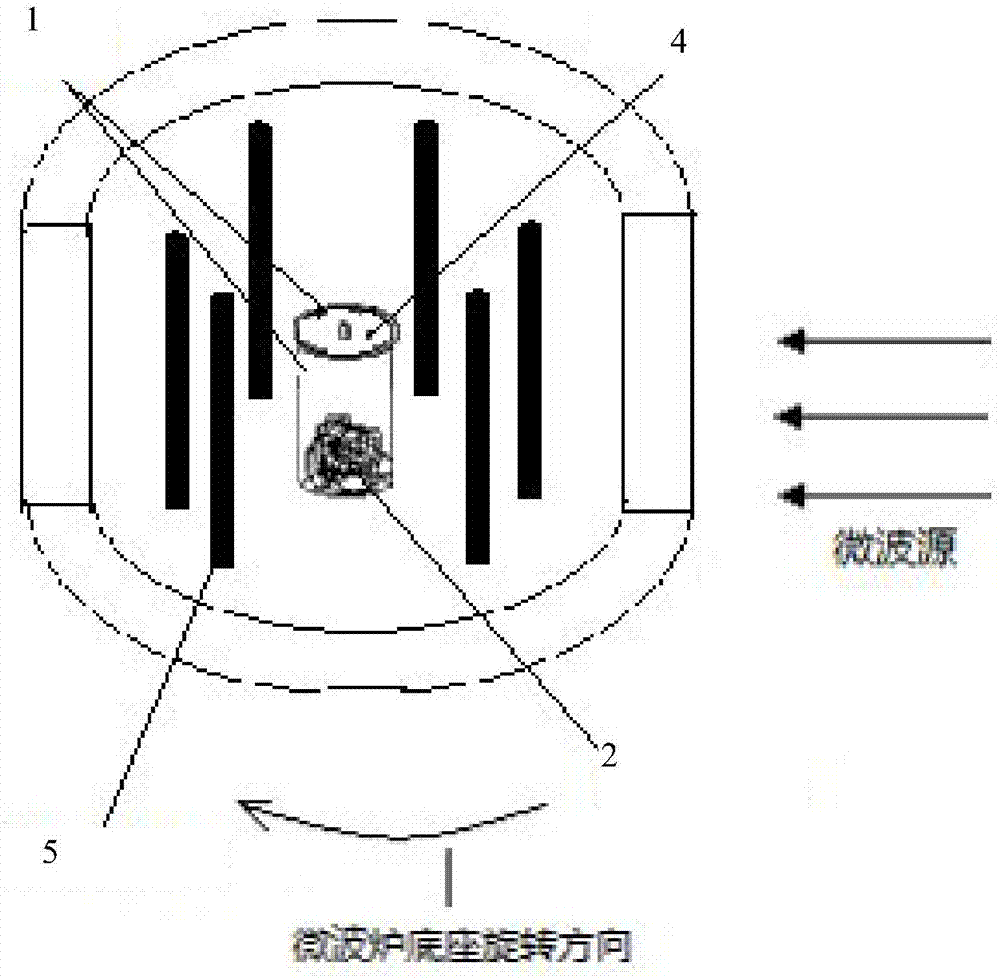

[0029] (2) Fill 150g of silicon carbide powder 5 into the annular gap between the first quartz glass 1 and the second quartz glass 3, and put 200mg of graphene oxide 2 prepared in step (1) into the first quartz Glass 1 (eg figure 1 shown), then put it into an industrial microwave oven to evacuate to make the absolute pressure in the furnace lower than 0.1MPa, pass argon gas to normal pressure and then evacuate, repeat this process three times. Before turni...

Embodiment 3

[0032]A method for preparing graphene by solid-phase assisted microwave reduction of graphene oxide, specifically comprising the steps of:

[0033] (1) Sonicate the mixture of graphite oxide and water for 45min at 0.5L, 80W, 40KHz, centrifuge the suspension obtained after sonication at 2500rpm for 30min, take the supernatant and dry it in a blast drying oven at 60°C for 24h Collect to obtain graphene oxide fragments;

[0034] The mixed solution of described graphite oxide and water is prepared by an improved Hummers method;

[0035] (2) Fill 80g of graphite powder 5 into the annular gap between the first quartz glass 1 and the second quartz glass 3, and put 100mg of graphene oxide 2 prepared in step (1) into the first quartz glass Cup 1 (as in figure 1 shown), then put it into an industrial microwave oven to evacuate to make the absolute pressure in the furnace lower than 0.1MPa, pass argon gas to normal pressure and then evacuate, repeat this process three times. Before tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com