Piezoelectric drive type two-degree-of-freedom high-precision microoperation clamp

A piezoelectric drive and micro-operation technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot meet the requirements of PMOF rotation at an angle, cannot guarantee the precise positioning of PMOF, and is not suitable for mass production. Achieve the effects of measurement and real-time feedback, compact structure, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

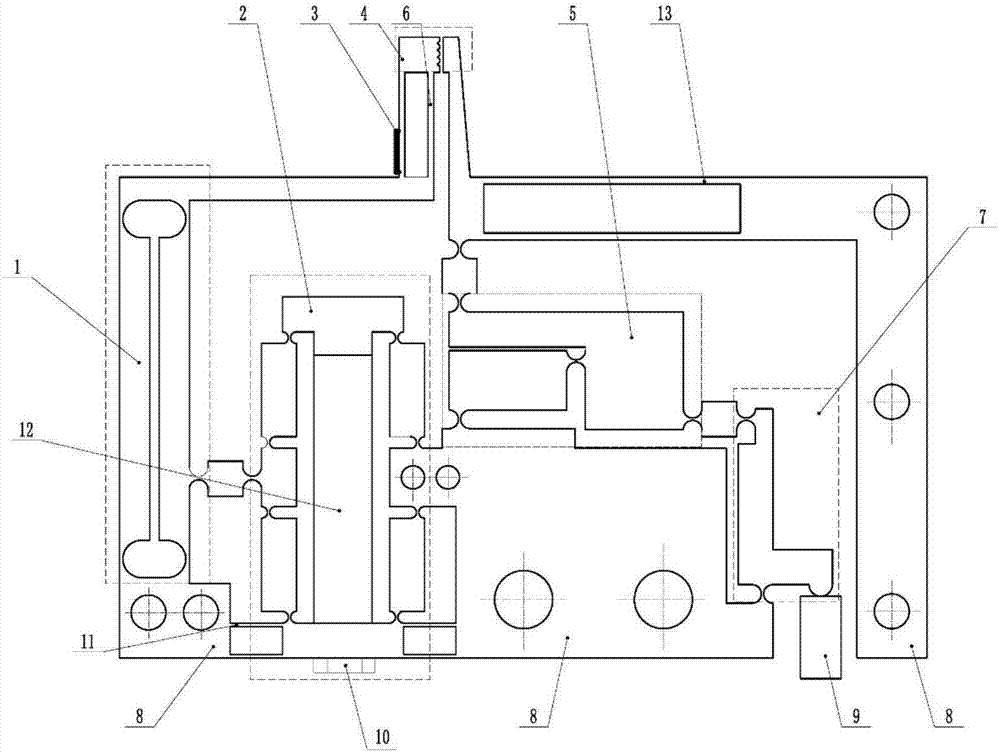

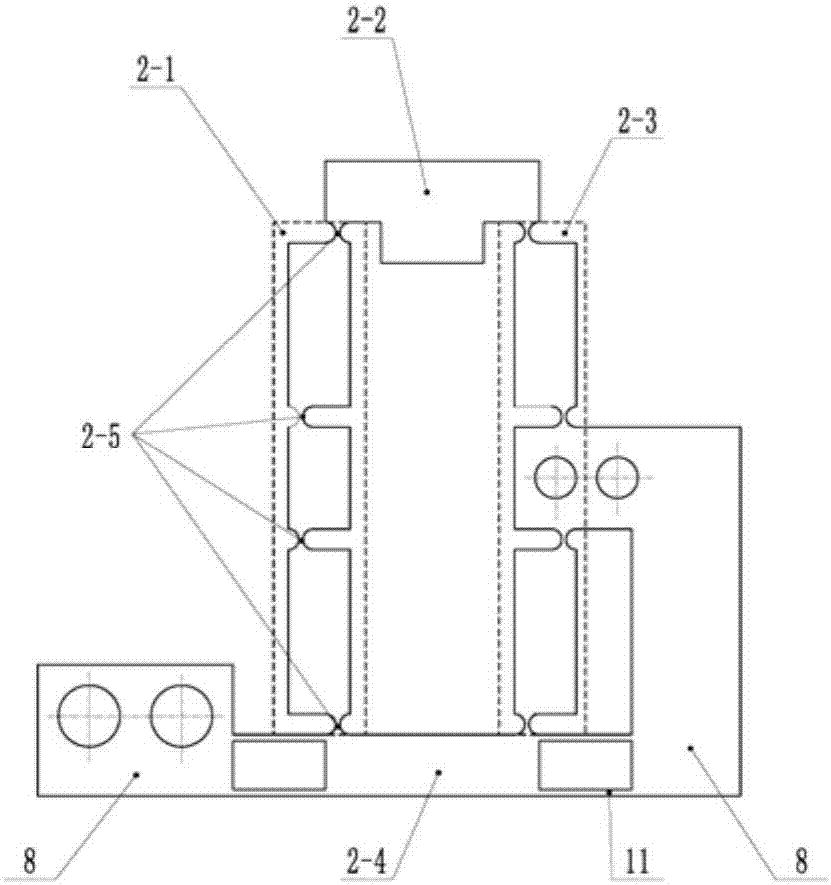

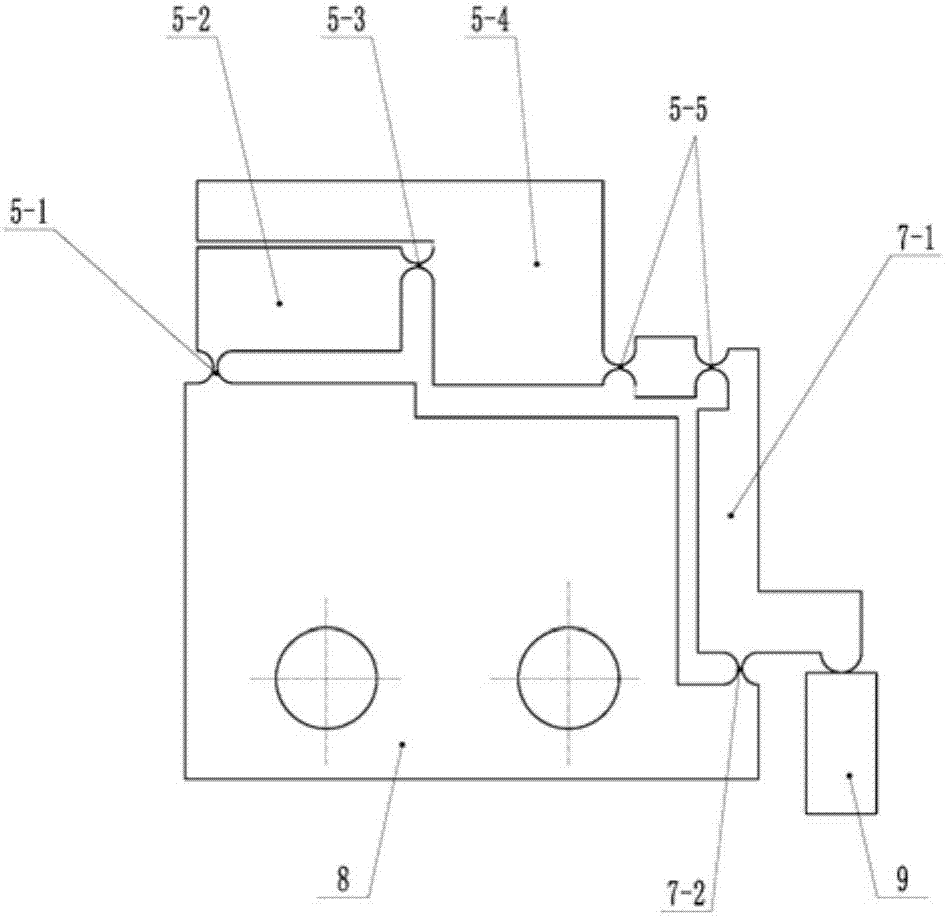

[0022] see Figure 1 ~ Figure 4 , the embodiment of the present invention protects a piezoelectric-driven two-degree-of-freedom high-precision micro-operation gripper, which is integrally formed by wire cutting of a plate, and includes a bridge-type displacement amplification mechanism 2 and an SR displacement amplification mechanism 5, The lever amplifying mechanism 7 and the base body 8, the bridge type displacement amplifying mechanism 2, the SR displacement amplifying mechanism 5, and the lever amplifying mechanism 7 are distributed on both sides of the center line, which is an asymmetric structure.

[0023] The bridge-type displacement amplifying mechanism 2 is distributed on the left side of the mechanism, and is provided with two movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com