Stepped forging forming method for super-huge type titanium alloy propeller hub forged piece

A titanium alloy and super-large technology, which is applied in the field of step-by-step forging of super-large titanium alloy propeller hub forgings, can solve the problems of large-scale mold casting technology not being able to keep up, mold life not being guaranteed, and large investment in research and development of forgings. Achieve the effects of improving metal flow direction, shortening processing cycle and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] The main chemical element content (percentage by weight) of the TB6 titanium alloy is: 2.6% to 3.4% of Al, 9.0% to 11.0% of V, 1.6% to 2.2% of Fe, and 0.9% to 1.5% of Ni , C content 0.05%, N content 0.05%, H content 0.015%, Y content 0.005%, other elements single ≤ 0.10% and total ≤ 0.30%, the balance is Ti.

[0025] The steps of this method are as follows:

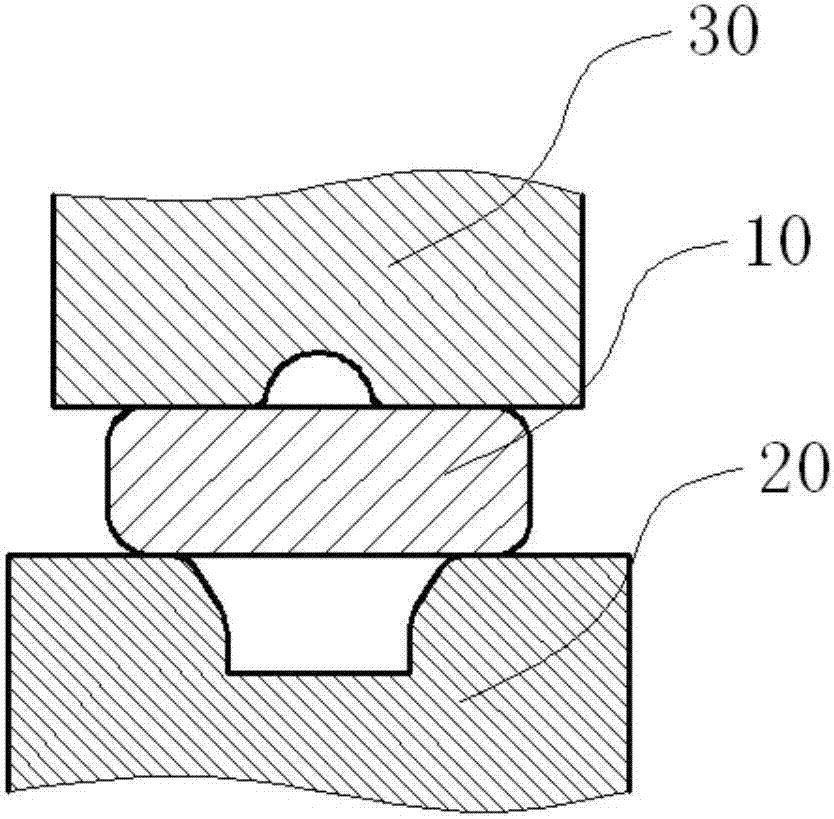

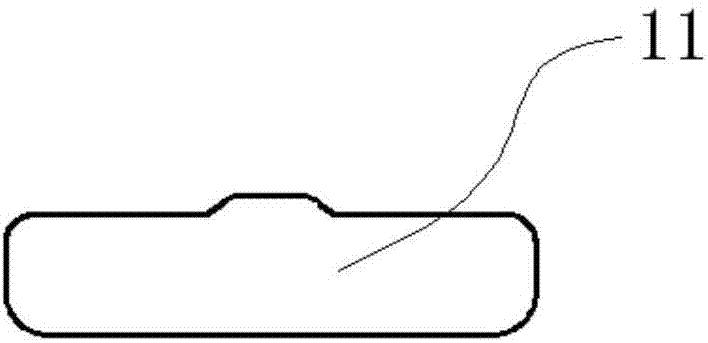

[0026] Cut the titanium alloy into rods according to certain specifications, heat the titanium alloy rods to 1180±20°C, keep them warm at an effective thickness×(0.3~0.7)min / mm, and then upset them on a press to form a cake 10 ,Such as figure 1 As shown, the final forging temperature is ≥850°C; the upsetting process is allowed to be completed in multiple fires, and at the end of each fire, it needs to be returned to the furnace while it is hot and the holding time is halved; if there is any damage during the upsetting process, the damage must be removed before continuing ;During the upsetting process, the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com