Sound insulation structure and method for manufacturing sound insulation structure

A technology of soundproofing and processing methods, which is applied in the direction of manufacturing tools, soundproofing, building components, etc., can solve the problems of large structure and difficulty in low-frequency shielding, and achieve the effect of strong soundproof structure, high sturdiness and light soundproof structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

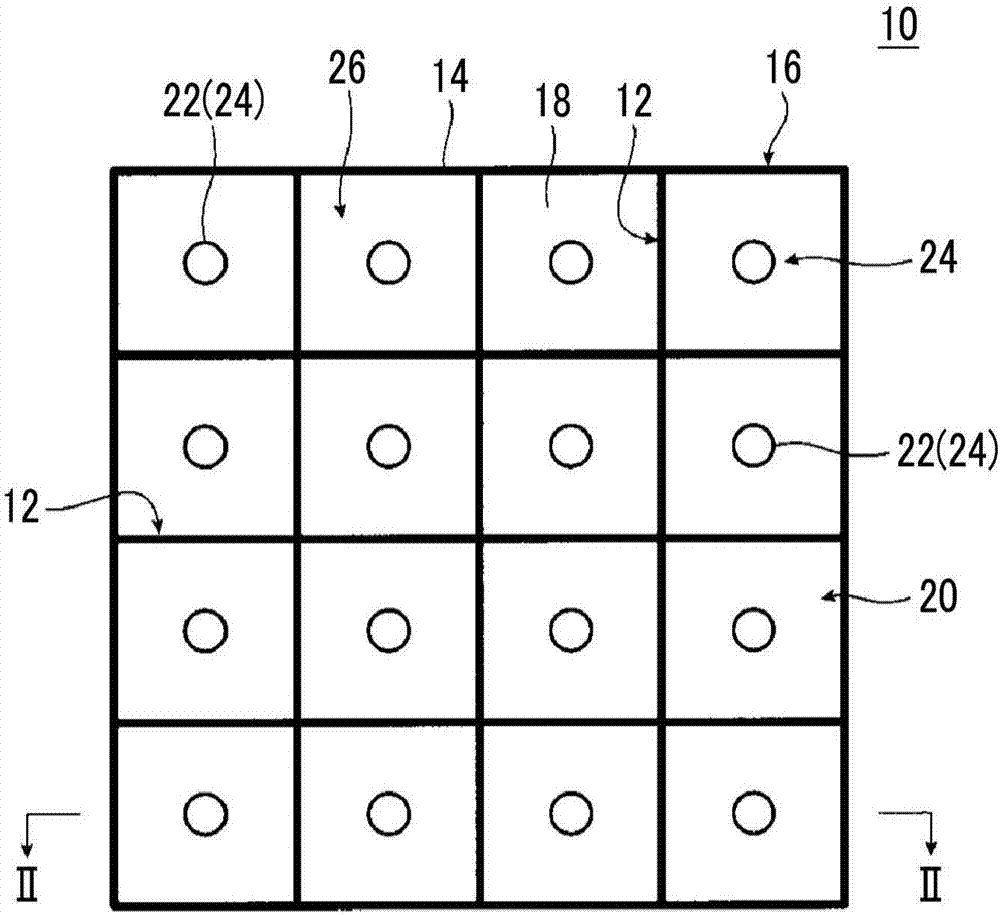

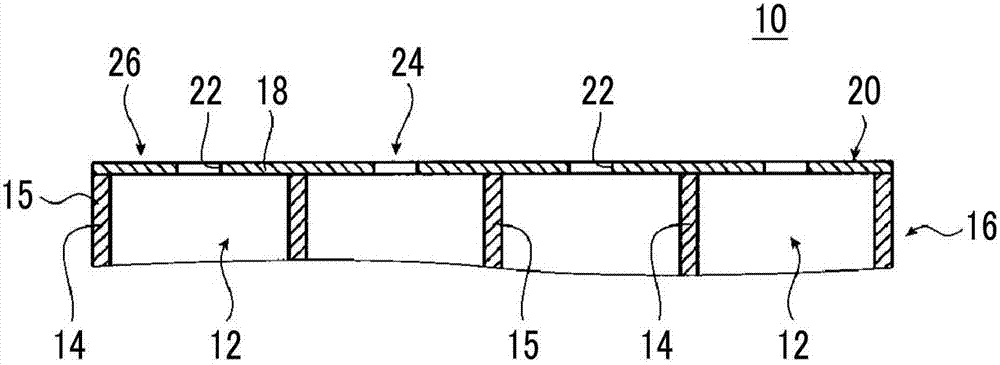

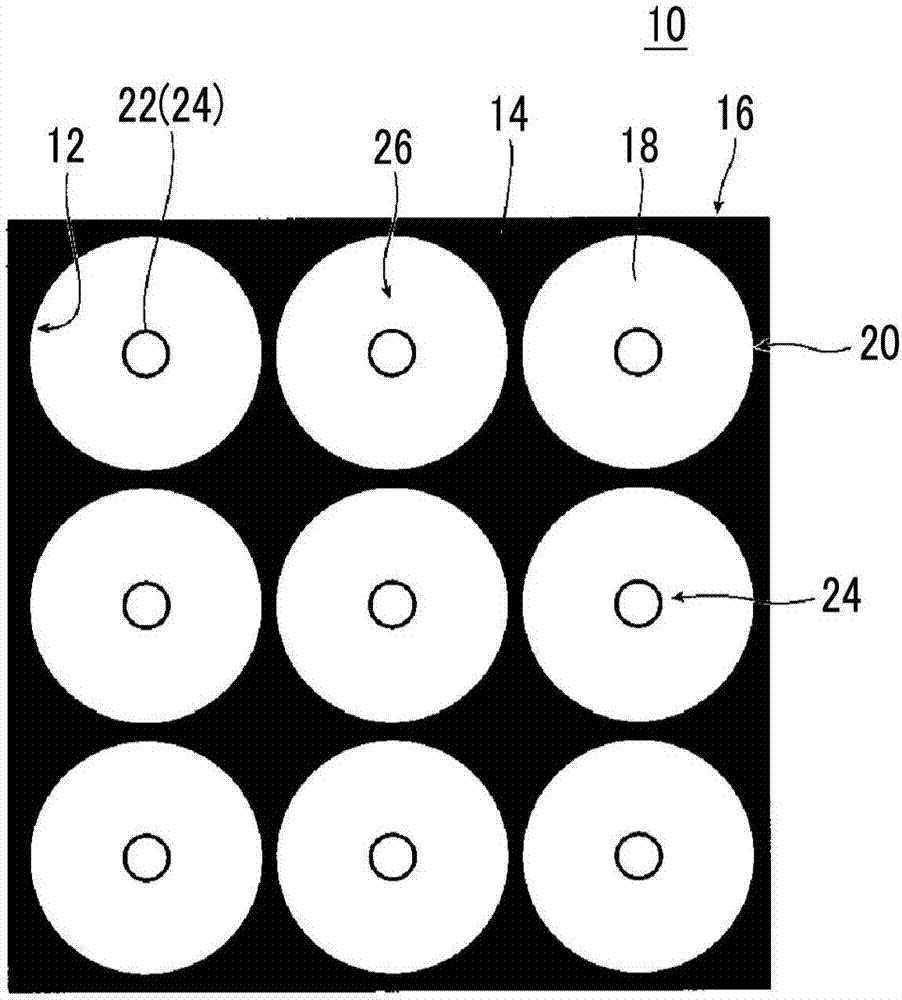

[0109] Here, if Figure 6 ~ Figure 11 As shown, the film 18 fixed to the frame 14 of the soundproof unit 26 has the first natural frequency with the smallest transmission loss (for example, 0 dB), and the resonant frequency as the frequency of the lowest natural mode. In the present invention, the present inventors have found that since the first natural frequency is determined by the structure including the frame 14 and the membrane 18, as Figure 6 and Figure 7 As shown, the values are substantially the same irrespective of the holes 22 pierced in the film 18 and further regardless of the presence or absence of the openings 24 . also, Figure 6 ~ Figure 11 These are graphs showing the sound insulation characteristics of the soundproof structures of Example 1 of the present invention, Comparative Example 1, and Examples 10, 21, 5, 23, and 38 of the present invention described later, and show transmission loss with respect to frequency.

[0110] Here, in the structure in...

Embodiment

[0195] The soundproof structure and the manufacturing method of the soundproof structure of this invention are demonstrated concretely based on an Example.

[0196]The design of the sound-proof structure is shown before the experiment to measure the acoustic properties was performed to manufacture an embodiment of the present invention.

[0197] The system of this soundproof structure is a system in which membrane vibration interacts with sound waves in the air, so it was analyzed using a coupling analysis of sound and vibration. Specifically, the sound module of COMSOLver5.0, which is the analysis software of finite element method, was used for design. First, the first natural frequency is obtained by natural vibration analysis. Next, an acoustic structural coupling analysis based on frequency sweep was performed in the boundary of the periodic structure, and the transmission loss at each frequency with respect to the sound wave incident from the front was obtained.

[0198...

Embodiment 2~7

[0220] A frame / film structure was produced in the same manner as in Example 1. It is known that the size of the hole 22 can be changed by changing the amount of heat generated by changing the laser irradiation time, so by optimizing the laser irradiation time / power, the desired hole 22 of 20 μm to 2000 μm can be obtained on the PET film. Table 3 shows the results including the shielding frequency in the soundproof structure of each Example thus obtained. also, Figure 10 The sound insulation characteristic of Example 5 is indicated by a dotted line in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com