Cold-proof and wear-resistant cable of grate cooler

A grate cooler and cable technology, which is applied in the field of clinker cooling, can solve the problems that the grate cooler cannot meet the cold and wear resistance requirements, and achieve the effects of shortening production preparation time, reducing manufacturing costs, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described below in conjunction with the accompanying drawings.

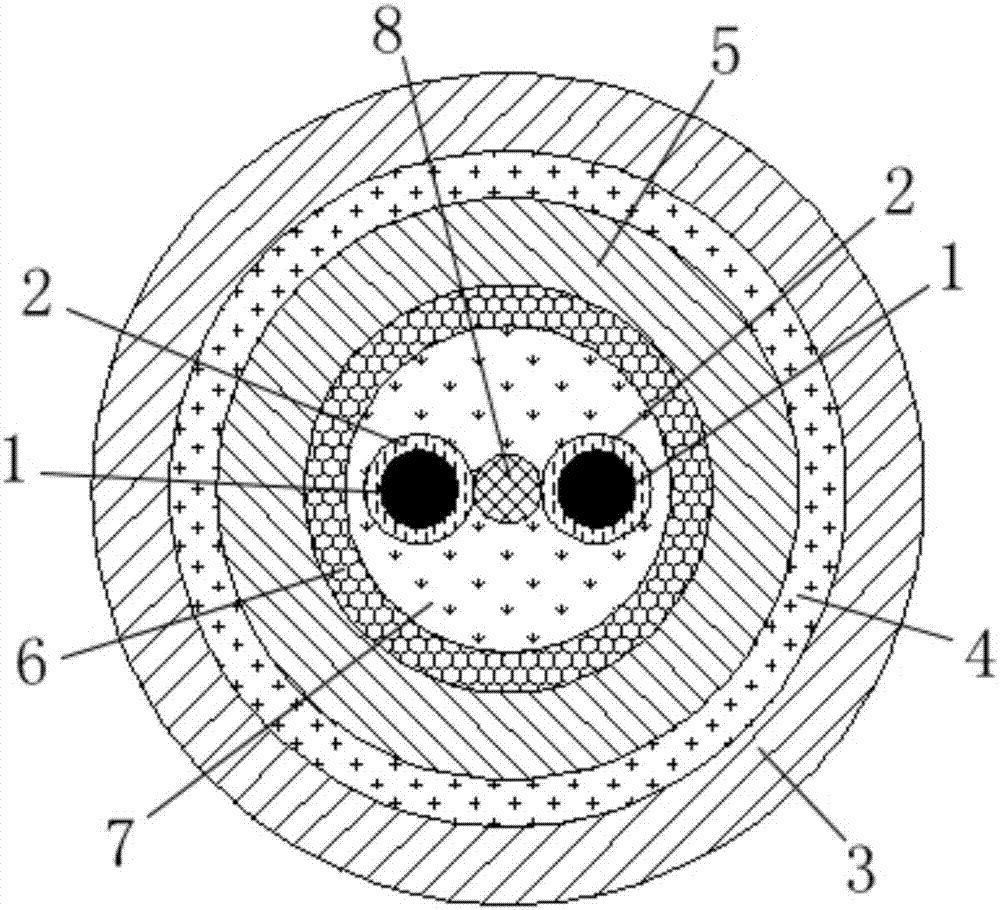

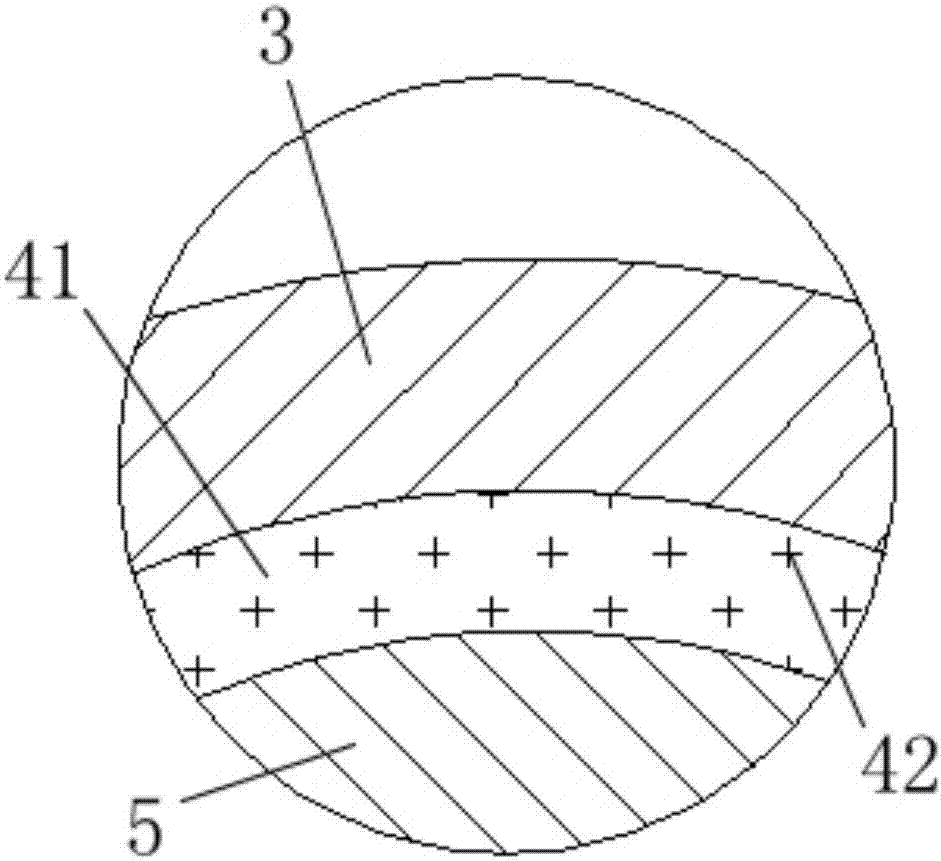

[0018] Such as figure 1 with figure 2 As shown, the grate cooler cold-proof and wear-resistant cable according to the present invention is characterized in that it includes two copper alloy cores 1, an insulating layer 2, an outermost wear-resistant layer 3, a cold-proof shielding layer 4, a fireproof layer 5, a winding Layer 6, filling layer 7 and central isolation layer 8, the outermost wear-resistant layer 3, cold-proof shielding layer 4, fireproof layer 5, wrapping layer 6 and filling layer 7 are wrapped sequentially from outside to inside, and two copper alloy cores 1 are fixed In the filling layer 7, the outer surface of each copper alloy core 1 is wrapped with an insulating layer 2, and the central isolation layer 8 is fixed between the two copper alloy cores 1, and the outermost wear-resistant layer 3 contains polyvinyl chloride resin , 2,4-di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com