Building process of upper assembly of maritime booster station

An offshore booster station and component technology, which is applied to buildings, artificial islands, industrial buildings, etc., can solve problems such as the inability to guarantee the symmetrical distribution of welding, reduce the stability of the offshore booster station, and the complex structure of the upper components, so as to reduce high-altitude operations. The effect of reducing the amount of offshore tooling and improving the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

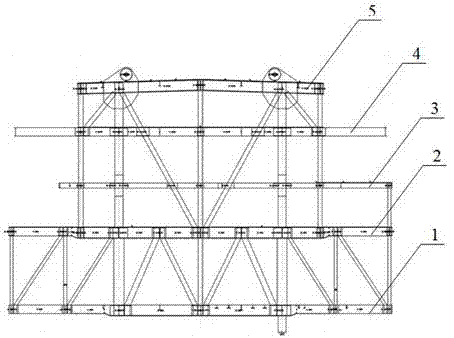

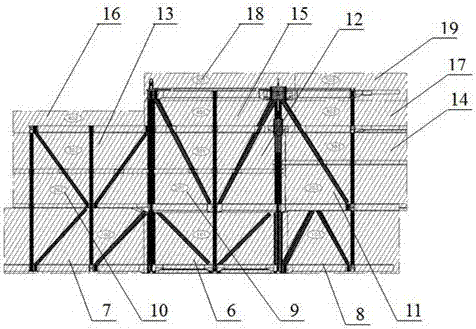

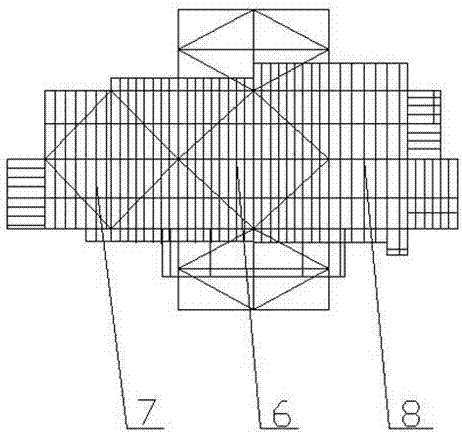

[0044] Such as figure 1 , figure 2 As shown, a construction process of the upper part of the offshore booster station, a construction process of the upper part of the offshore booster station, the upper part is made of one-story, two-story, three-story, four-story, five-story steel structure buildings The overall steel structure building, the adjacent two-story steel structure buildings are connected by stairs and the bottom of each steel structure building is a deck composed of multiple steel structures, and there is also a bridge between adjacent two-story steel structure buildings. There are two evacuation stairs;

[0045] The one-story steel structure building of the overall steel structure building is a cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com