Aluminum alloy anode oxide film with porous subsurface layer and wear-resistant surface layer and preparation method of aluminum alloy anode oxide film

An anodic oxidation film, anodic oxidation technology, applied in the direction of anodic oxidation, surface reaction electrolytic coating, coating, etc., can solve the problems of decreased wear resistance, no significant improvement in the wear resistance of aluminum alloys, and reduced surface hardness. Improve the wear resistance, the method is simple and easy to operate, and the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

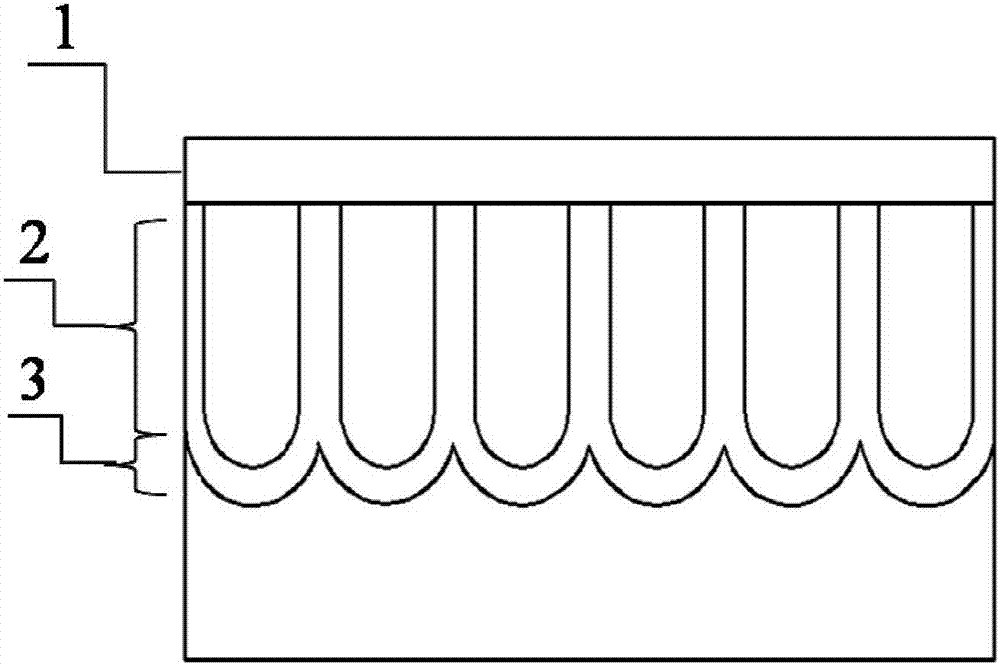

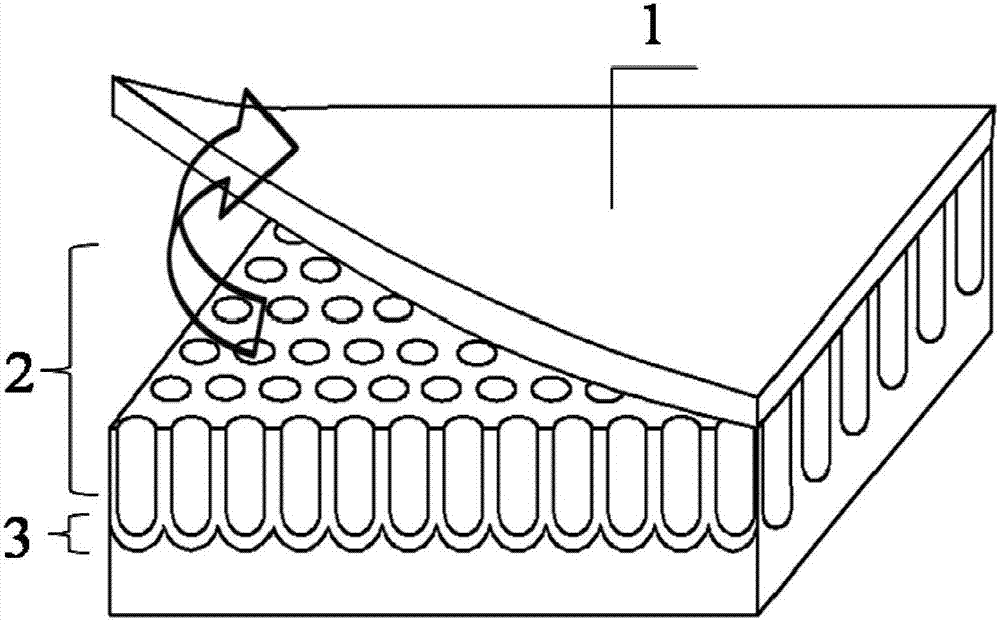

[0027] In this embodiment, the anodized film on the surface of the aluminum alloy substrate has a three-layer structure, such as figure 1 As shown, from the aluminum alloy base to the surface are the shielding layer 3 , the porous subsurface layer 2 , and the wear-resistant surface layer 1 . figure 2 is a schematic diagram of the three-dimensional structure of the anodized film.

[0028] The preparation method of the anodic oxidation film on the surface of the above-mentioned aluminum alloy substrate comprises the following steps:

[0029] (1) mechanical polishing

[0030] The aluminum alloy substrate is polished in three stages. Firstly, the aluminum alloy is roughly polished, then finely polished, and finally finely polished to obtain a mirror effect.

[0031] (2) Degreasing treatment

[0032] Degreasing the polished aluminum alloy, the degreasing agent is lye with a mass fraction of 10%, and the lye is at least one of sodium hydroxide, sodium carbonate and sodium phosph...

Embodiment 2

[0045] In this embodiment, the anodized film on the surface of the aluminum alloy substrate has a three-layer structure, that is, from the aluminum alloy substrate to the surface, there are a shielding layer, a porous subsurface layer, and a wear-resistant surface layer.

[0046] The preparation method of the anodic oxidation film on the surface of the above-mentioned aluminum alloy substrate comprises the following steps:

[0047](1) mechanical polishing

[0048] The aluminum alloy substrate is polished in three stages. Firstly, the aluminum alloy is roughly polished, then finely polished, and finally finely polished to obtain a mirror effect.

[0049] (2) Degreasing treatment

[0050] Degreasing the polished aluminum alloy, the degreasing agent is lye with a mass fraction of 15%, and the lye is at least one of sodium hydroxide, sodium carbonate and sodium phosphate, and is treated at 30° C. for 13 minutes.

[0051] (3) Anodizing

[0052] Put the degreased aluminum alloy s...

Embodiment 3

[0063] In this embodiment, the anodized film on the surface of the aluminum alloy substrate has a three-layer structure, that is, from the aluminum alloy substrate to the surface, there are a shielding layer, a porous subsurface layer, and a wear-resistant surface layer.

[0064] The preparation method of the anodic oxidation film on the surface of the above-mentioned aluminum alloy substrate comprises the following steps:

[0065] (1) mechanical polishing

[0066] The aluminum alloy substrate is polished in three stages. Firstly, the aluminum alloy is roughly polished, then finely polished, and finally finely polished to obtain a mirror effect.

[0067] (2) Degreasing treatment

[0068] Degreasing the polished aluminum alloy, the degreasing agent is lye with a mass fraction of 15%, and the lye is at least one of sodium hydroxide, sodium carbonate and sodium phosphate, and is treated at 40° C. for 10 minutes.

[0069] (3) Anodizing

[0070] Put the degreased aluminum alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com