Transparent epoxy adhesive and application thereof

An epoxy adhesive, transparent technology, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problems of unable to meet the requirements of use, poor compatibility of epoxy resin, affecting the adhesion of adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

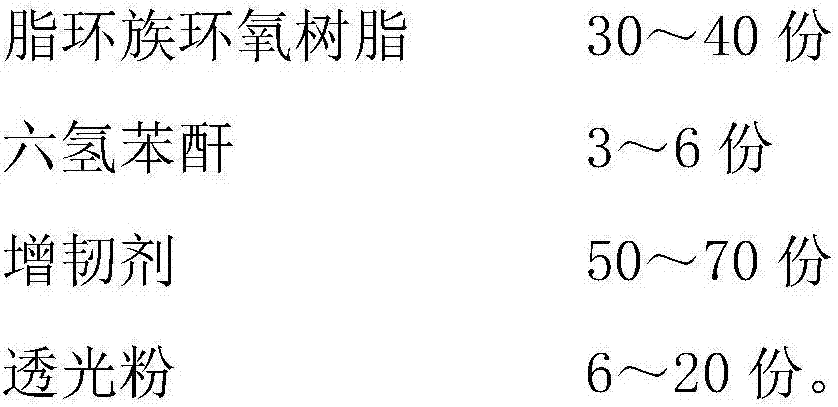

Method used

Image

Examples

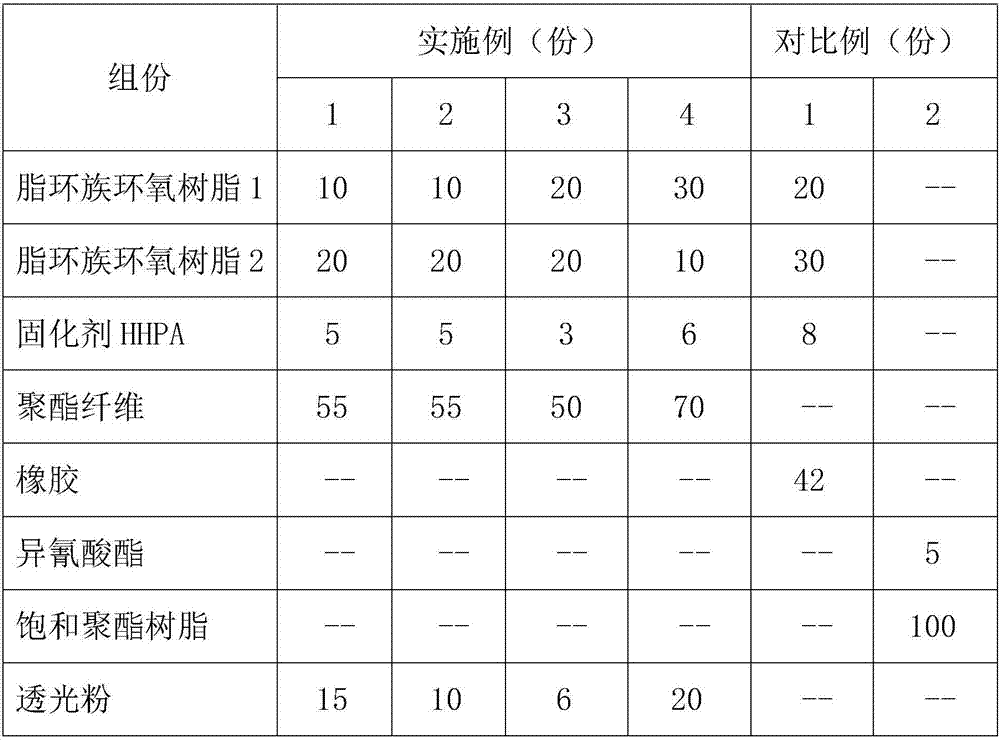

Embodiment 1-4

[0030] The preparation method of embodiment 1-4 and comparative example 1-2 is as follows:

[0031] Add each component according to the ratio in Table 1, add a certain amount of methyl ethyl ketone and stir to make a 40% transparent adhesive. (embodiment 1-4 is transparent epoxy adhesive, hereinafter collectively referred to as transparent adhesive to facilitate description of preparation method.)

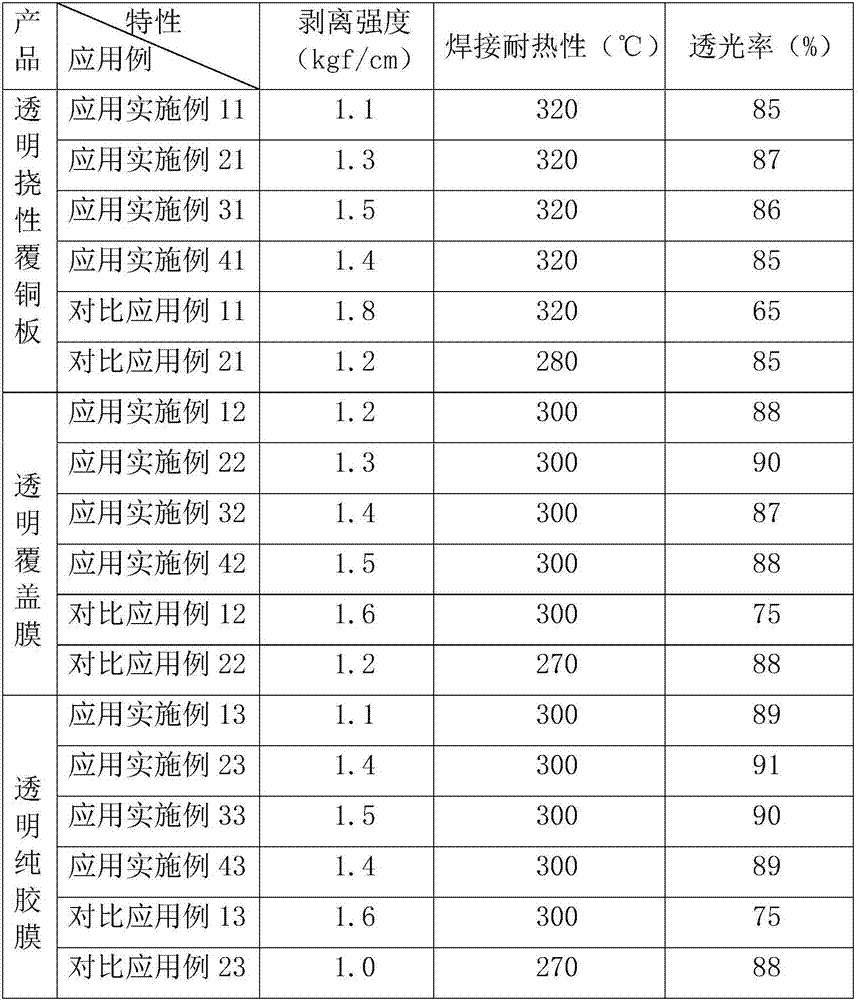

[0032] Examples 1-4 and Comparative Examples 1-2 were applied to prepare transparent flexible copper-clad laminates, transparent cover films and transparent pure rubber films, respectively.

[0033] The preparation method of the transparent flexible copper clad laminate is as follows:

[0034] Use a coating machine to coat the transparent adhesive on the transparent polyimide film, the thickness of the coating is 12 μm after drying, and then dry it in an oven at 150 ° C for 5 minutes to cure to a semi-cured state, and then use a temperature of 100 ° C and Under the pressure of 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com