Cerium-based catalyst loaded with transition metal as well as preparation method and purpose thereof

A technology of cerium-based catalysts and transition metals, applied in the field of cerium-based catalysts loaded with transition metals and its preparation, can solve the problems of poor high temperature thermal stability, decreased N2 selectivity, narrow operating temperature window, etc., and achieve high selectivity and operation The effect of wide temperature window and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

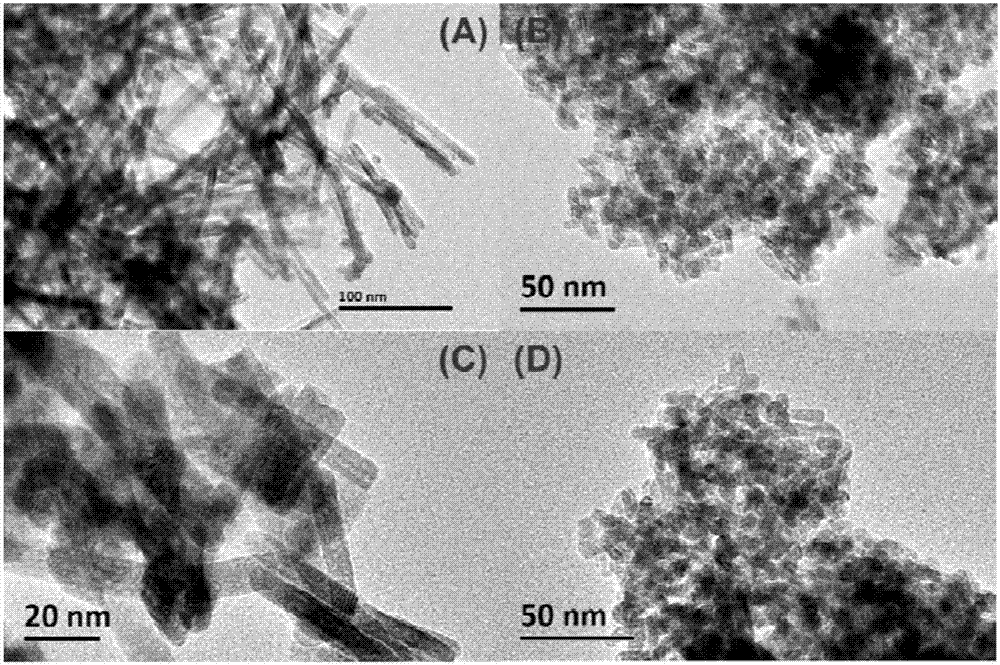

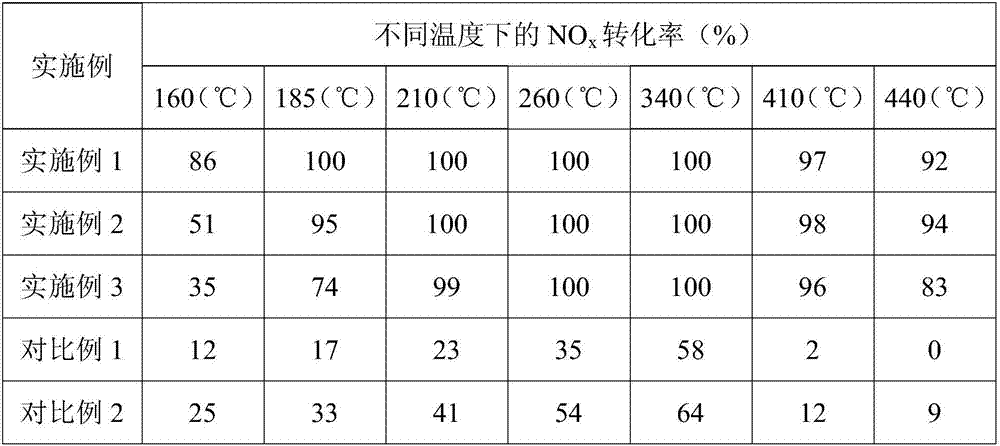

Embodiment 1

[0045] The cerium-based catalyst of the load transition metal of the present embodiment, by CeO 2 It is composed of the carrier and the transition metal oxide active component loaded on the carrier, the transition metal salt is niobium oxalate, CeO 2 Carrier is CeO 2 nanoparticles, CeO 2 The mass of carrier is 100%, and the mass of niobium oxalate is 20 %.

[0046] The preparation method of the cerium-based catalyst supporting transition metal comprises the following steps:

[0047] 1) Dissolve cerium nitrate in water, add sodium hydroxide and stir for 1 h, wherein the mass ratio of cerium nitrate to sodium hydroxide is 0.15:1, carry out hydrothermal reaction at 30° C. for 12 h, and the precipitated product obtained is washed with deionized water and Washed with absolute ethanol, dried in an oven at 60°C, and calcined in a muffle furnace at 550°C for 4 hours in an air atmosphere to obtain CeO 2 carrier;

[0048] 2) with the CeO obtained in step 1) 2 Add the nanoparticle...

Embodiment 2

[0050] The cerium-based catalyst of the load transition metal of the present embodiment, by CeO 2 It is composed of the carrier and the transition metal oxide active component loaded on the carrier, the transition metal salt is niobium oxalate, CeO 2 Carrier is CeO 2 For the nanorod, the mass of niobium oxalate is 20% based on the mass of the CeO2 carrier as 100%.

[0051] The preparation method of the cerium-based catalyst supporting transition metal comprises the following steps:

[0052] 1) Dissolve cerium nitrate in water, add sodium hydroxide and stir for 1 h, wherein the mass ratio of cerium nitrate to sodium hydroxide is 1:5, and react at 120°C for 12 h, and the obtained precipitated product is washed with deionized water and anhydrous Washed with ethanol, dried in an oven at 60 °C, and calcined in a muffle furnace at 550 °C for 4 h in an air atmosphere to obtain CeO 2 carrier;

[0053] 2) with the CeO obtained in step 1) 2 The nanorod carrier was added into niobiu...

Embodiment 3

[0055] The difference between this example and Example 2 is that the transition metal salt is ammonium metatungstate, and the rest are the same as Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com