Preparation method of composite silicon carbon negative electrode material

A negative electrode material, silicon carbon technology, applied in the field of preparation of composite silicon carbon negative electrode materials, can solve the problems of increasing material cost, difficulty in inserting silicon powder into the gap of expanded graphite, and increasing material cost, so as to improve buffering effect and reduce material cost , the effect of performance controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

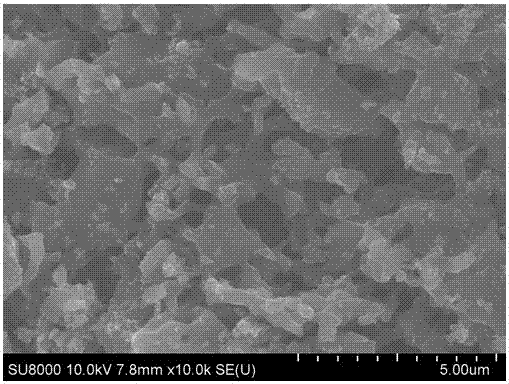

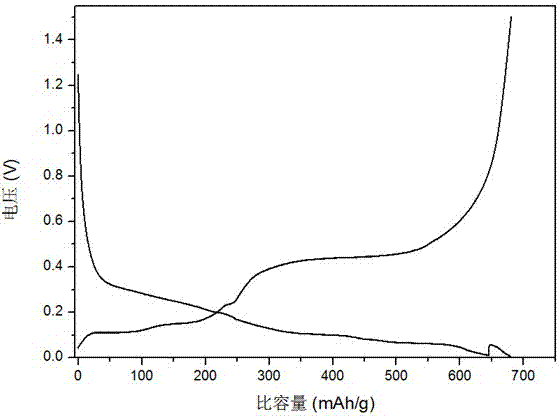

Image

Examples

Embodiment 1

[0021] 50 g of dimethylformamide was added to 6 g of expanded graphite, ultrasonically treated for 30 min, and 90 g of tetraethyl orthosilicate was added to the expanded graphite suspension. A 5% hydrochloric acid solution was prepared, and 8 g of hydrochloric acid aqueous solution was added to the above suspension to prepare a precursor suspension. 140 g of deionized water was slowly added dropwise to the precursor suspension, and vigorously stirred, and after standing for 1.5 hours, the suspension was dried at 80° C. to obtain the precursor. The precursor was fully mixed with 45 g of Mg powder, placed in an atmosphere furnace, heated to 750°C for 4 hours under an argon atmosphere; the reaction product was pickled, washed with water, dried, and crushed to obtain a silicon-rich material; Weigh 80 g of polyvinylpyrrolidone, dissolve it in 400 g of ethanol, add 5 g of silicon-rich materials after fully dissolving, stir well to form a suspension, and make silicon-carbon composite...

Embodiment 2

[0023] Add 150 g of dimethylacetamide to 15 g of expanded graphite, ultrasonically treat it for 1 h, add 300 g of tetraethyl orthosilicate to the expanded graphite suspension; prepare 10% ammonia solution, and add 150 g of ammonia solution to the In the above suspension, the precursor suspension was prepared; 400g of deionized water was slowly added dropwise to the precursor suspension, and vigorously stirred, and after standing for 4 hours, the suspension was dried at 80°C dry to obtain a precursor; fully mix the precursor with 150 g of Mg powder, put it into an atmosphere furnace, and heat it to 700°C for 3 hours under an argon atmosphere; the reaction product is pickled, washed with water, dried, and then pulverized. Obtain a silicon-rich material; weigh 100 g of polyacrylonitrile, dissolve it in 200 g of dimethylacetamide, add 15 g of silicon-rich material after fully dissolving, stir well to form a suspension, and make a silicon-carbon composite by electrospinning The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com