LED epitaxial growth method

An epitaxial growth and epitaxy technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of increasing the number of electron-hole pairs in the multi-quantum well layer, affecting the luminous efficiency of LEDs, and improving the level of hole injection. , the effect of increasing the number and reducing the working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

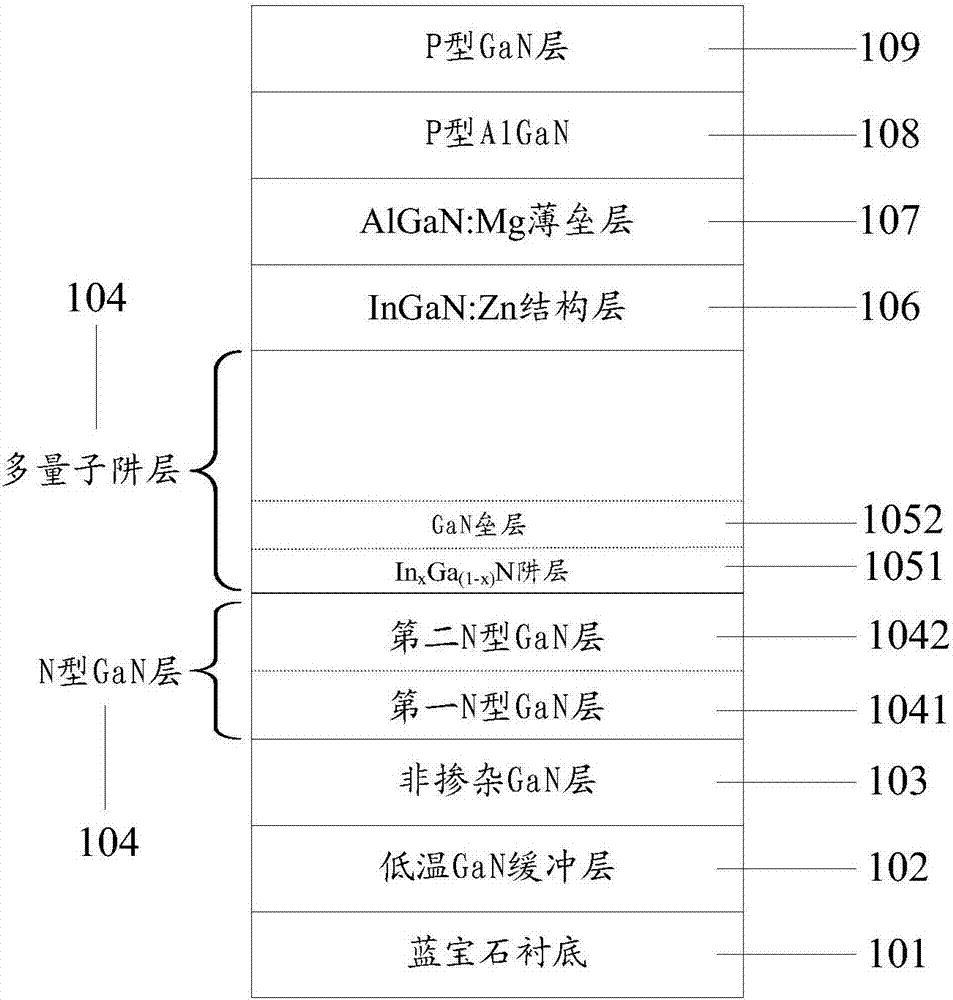

[0053] This embodiment provides an LED epitaxial growth method, figure 1 A schematic structural diagram of the LED epitaxy prepared by the LED epitaxy growth method in this embodiment is given, please refer to figure 1 , the LED epitaxy, including: a low-temperature GaN buffer layer 102, a non-doped GaN layer 103, an N-type GaN layer 104, a multi-quantum well layer 105, an InGaN:Zn structure layer 106, an AlGaN: Mg thin barrier layer 107 , P-type AlGaN layer 108 and P-type GaN layer 109 . Wherein, the N-type GaN layer 104 includes a first N-type GaN layer 1041 and a second N-type GaN layer 1042; the multi-quantum well layer 105 includes alternately grown In x Ga (1-x) The alternating period of the N well layer 1051 and the GaN barrier layer 1052 is controlled at 7-15.

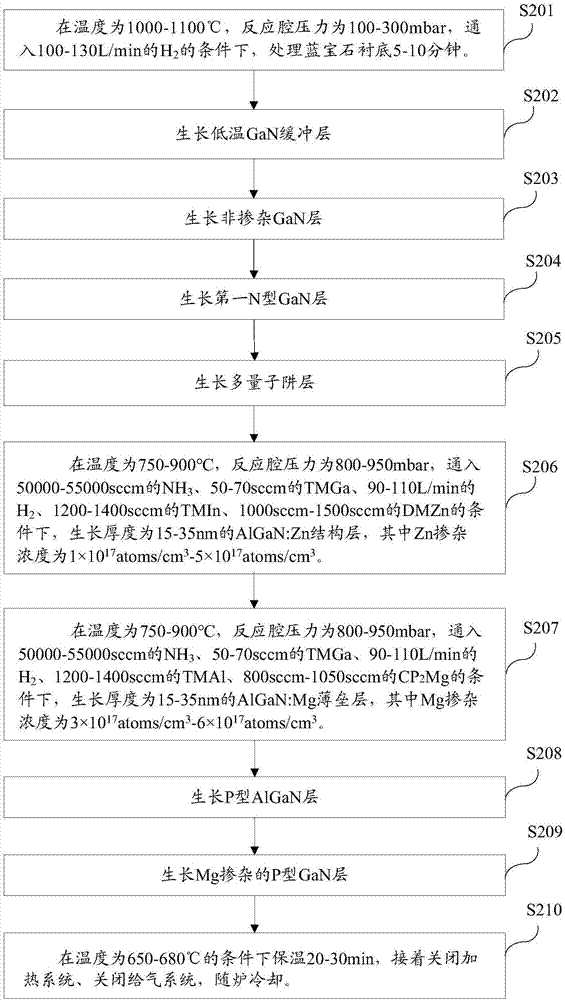

[0054] The LED epitaxial growth method provided in this embodiment uses MOCVD to grow high-brightness GaN-based LED epitaxial wafers, and uses high-purity H 2 or high purity N 2 or high purity H 2 and hig...

Embodiment 2

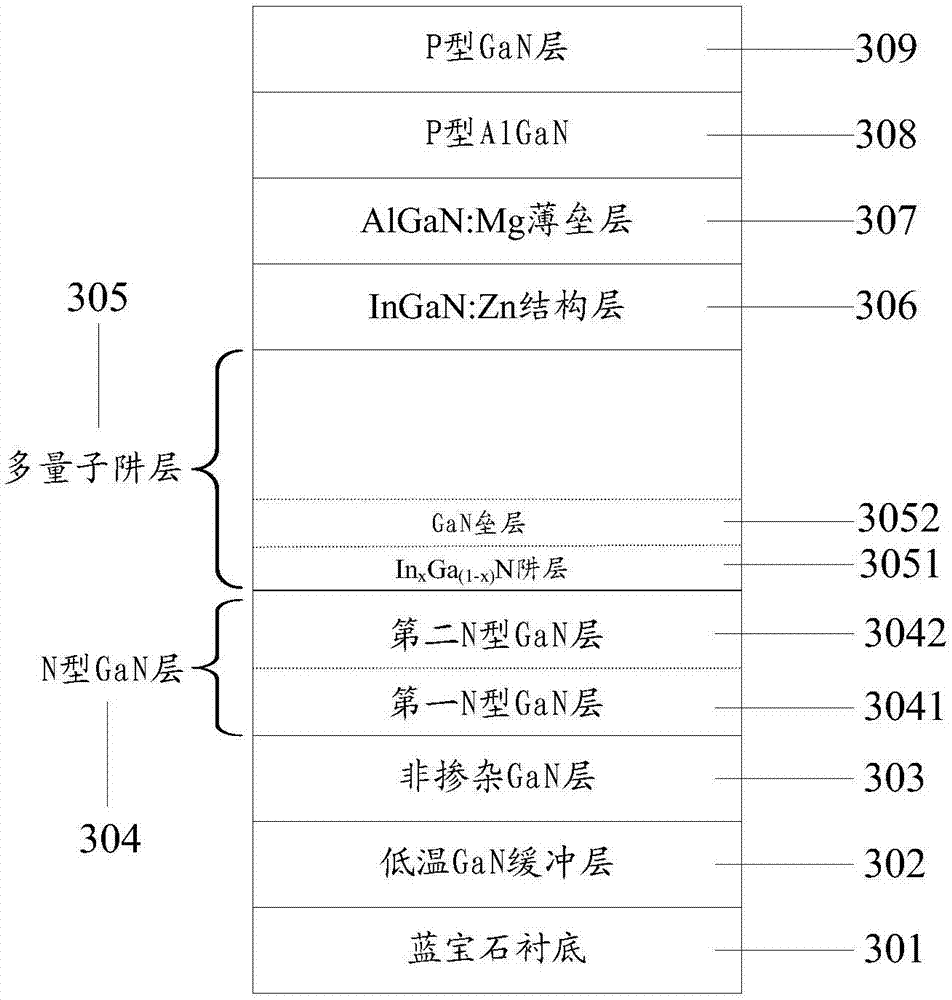

[0067] This embodiment provides an LED epitaxial growth method, image 3 A schematic structural diagram of the LED epitaxy prepared by the LED epitaxy growth method in this embodiment is given, please refer to image 3 , the LED epitaxy, including: a low-temperature GaN buffer layer 302, a non-doped GaN layer 303, an N-type GaN layer 304, a multi-quantum well layer 305, an InGaN:Zn structure layer 306, an AlGaN: Mg thin barrier layer 307 , P-type AlGaN layer 308 and P-type GaN layer 309 . Wherein, the N-type GaN layer 104 includes a first N-type GaN layer 1041 and a second N-type GaN layer 1042; the multi-quantum well layer 305 includes alternately grown In x Ga (1-x) The alternating period of the N well layer 3051 and the GaN barrier layer 3052 is controlled at 7-15.

[0068] The LED epitaxial growth method provided in this embodiment uses MOCVD to grow high-brightness GaN-based LED epitaxial wafers, and uses high-purity H 2 or high purity N 2 or high purity H 2 and hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com