Conductive silver paste, method for preparing same and application of conductive silver paste

A technology of conductive silver paste and silver powder, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. The formation of serous film and other problems can achieve the effect of improving the effect of defrosting and defogging, avoiding uneven or excessive thickness of the coating layer, and improving the effect of thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing the conductive silver paste described in the above technical solution, comprising: mixing the spherical silver powder, the lead-free glass powder with the mixed slurry comprising the organic solvent, cellulose and additives to obtain the conductive silver paste .

[0045] The present invention has no special requirements on the preparation method of the mixed slurry of the organic solvent, cellulose and additives, and the preparation method of the mixed material well known to those skilled in the art can be used. In the present invention, the cellulose is preferably mixed with an organic solvent and then mixed with an additive. In the present invention, the preparation of the mixed slurry is preferably carried out under the condition of heating in a water bath, and the temperature of the heating in the water bath is preferably 80-90°C.

[0046] In the present invention, the mixed slurry including organic solven...

Embodiment 1

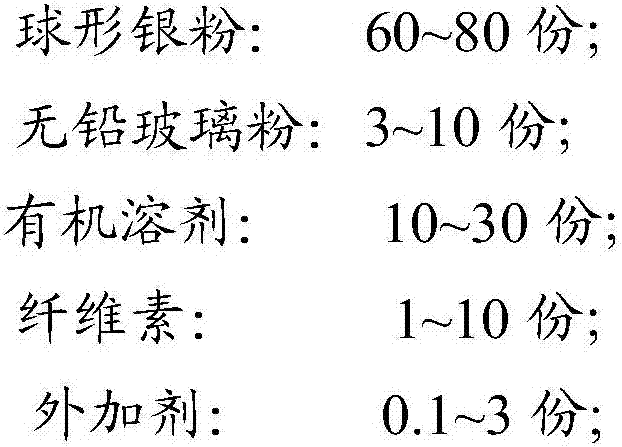

[0058] A conductive silver paste, comprising:

[0059]

[0060] The D50 of the above fine silver powder is 1.63 μm, the bulk density is 1.22 g / ml, and the tap density is 2.55 g / ml; the D50 of the coarse silver powder is 2.01 μm, the bulk density is 1.58 g / ml, and the tap density is 3.23 g / ml.

[0061] The D50 of the above-mentioned lead-free glass powder is 5 μm, and at 300°C, the coefficient of linear expansion is 6.5×10 -6 / °C, the glass transition temperature is 450°C, and the sintering temperature is 560°C.

[0062] The preparation method of described conductive silver paste comprises:

[0063] The fine silver powder, the coarse silver powder and the lead-free glass powder are placed in a three-dimensional mixer for mixing according to the weight ratio to obtain a mixed powder for future use.

[0064] Mix butyl carbitol, terpineol, butyl carbitol acetate, ethyl cellulose, modified hydrogenated castor oil and lecithin at 90°C in proportion by weight, stir for 30 minu...

Embodiment 2

[0078] A conductive silver paste, comprising:

[0079]

[0080]

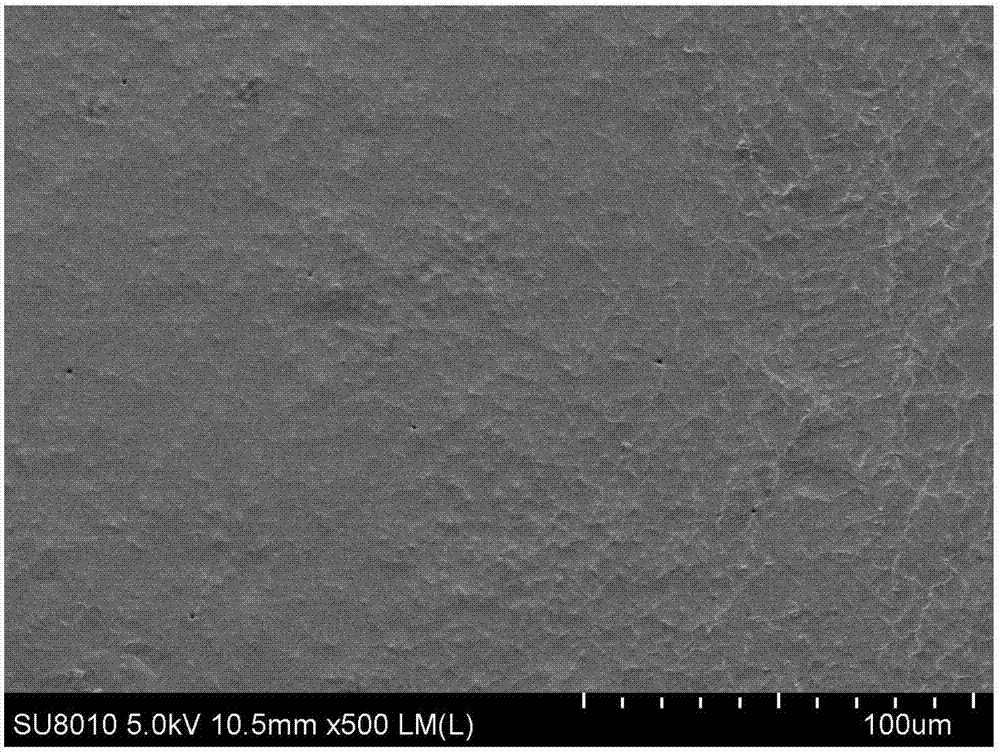

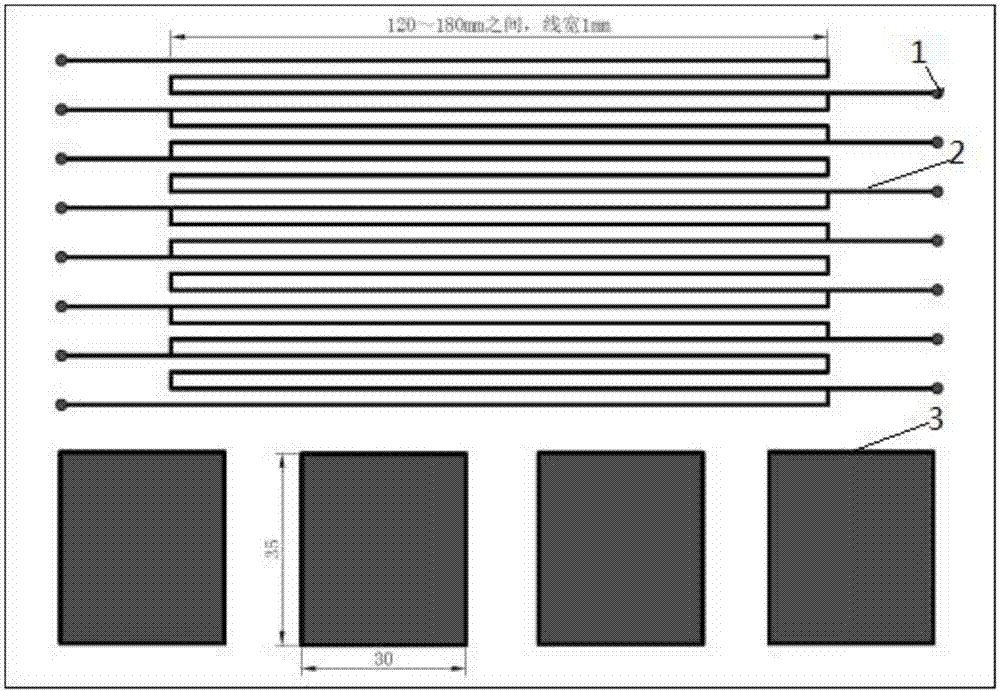

[0081] In the present embodiment, D50, bulk density and tap density of fine silver powder and coarse silver powder, D50, linear expansion coefficient, glass transition temperature and sintering temperature of lead-free glass powder, performance test method are all the same as embodiment 1, preparation process Same as Example 1, except that the conductive silver paste is obtained after grinding to 15 μm. Conductive silver paste 5g, according to figure 2 Printing, the thickness of the coating layer is 24 μm, drying at 140°C for 4 hours, and sintering at 670°C for 3 minutes to obtain a defrosting and defogging glass with a film thickness of 13 μm. The compactness of the silver paste film after sintering was tested, with figure 1 It is a SEM picture, according to the image, it can be seen that the silver paste film has good compactness; the performance test of the conductive silver paste and film is shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com