Environment-friendly antifriction and antioxidant non-sulfur phosphorus organic tungsten additive and lubricating oil containing same

An additive and environment-friendly technology, applied in the direction of additives, organic chemistry, lubricating compositions, etc., can solve the problems of limiting the application of tungsten series lubricating oil additives, low tungsten content, poor stability, etc., solve the problem of oil solubility, improve high temperature resistance Oxygen, good antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

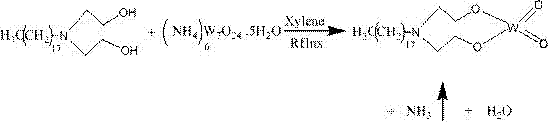

[0032] Weigh 64.2g of dihydroxyethyl octadecylamine into a 1000ml three-necked flask, add 0.5g of catalyst, and then add 300ml of toluene as a solvent, and reflux under magnetic stirring. Weigh 34g of ammonium tungstate pentahydrate aqueous solution, and slowly add it dropwise into a three-necked flask using a constant pressure dropping funnel. The temperature of the reaction system is controlled between 90 and 100°C, and the reaction time is about two hours. Use a water separator to separate the upper water layer, filter to obtain a grass-green product, and then vacuum-dry to obtain a grass-green solid, namely N-octadecyliminediethanol tungstate diester. The reaction equation is as follows:

[0033] .

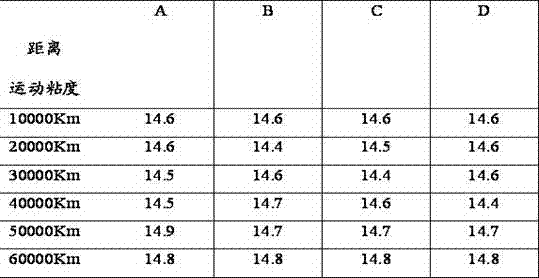

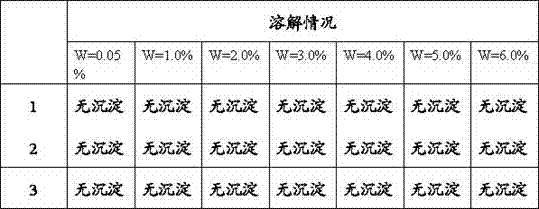

[0034] The N-octadecylimine diethanol tungstate diester additive prepared according to the steps of the above method was used for oil solubility determination. According to the mass fraction of 0.05, 1.0, 2.0, 3.0, 4.0, 5.0, 6.0 N-octadecyl imine diethanol tungstate diest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com