Dysprosium-doped lanthanum lithium molybdate fluorescent powder and preparation method thereof

A technology of lanthanum lithium molybdate and fluorescent powder, which is applied in the field of dysprosium-doped lanthanum lithium molybdate phosphor and its preparation, which can solve the problems of expensive raw materials, long preparation time, and health hazards, and achieve low pollution and short reaction time , the effect of improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

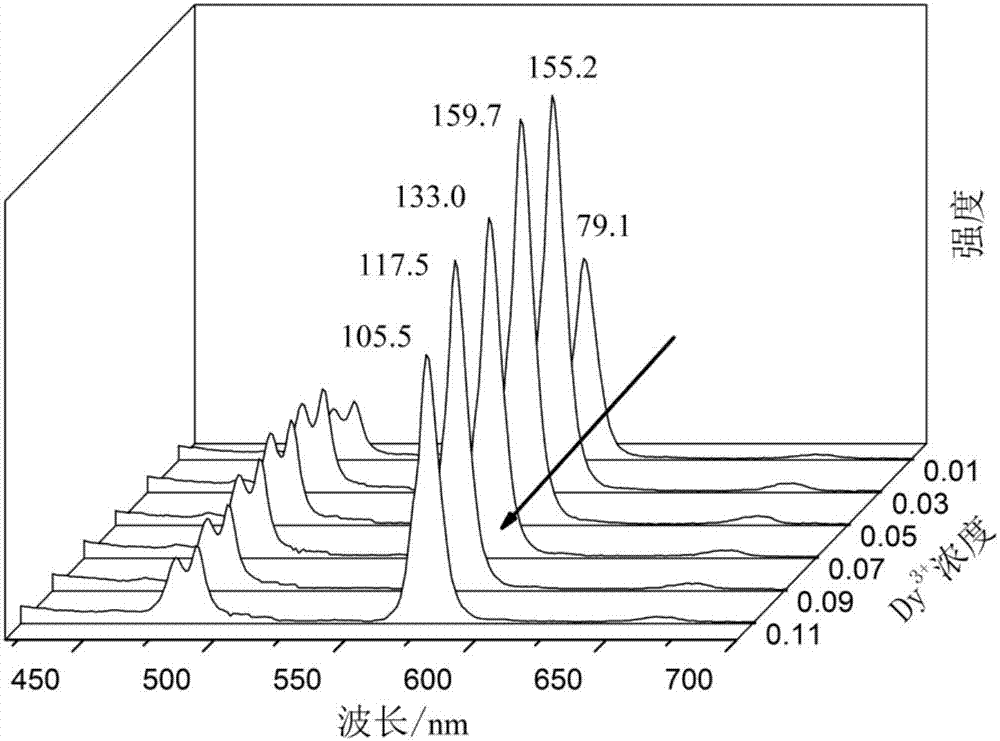

[0032] (1) Using Li 2 CO 3 , La 2 o 3 ,MoO 3 and Dy 2 o 3 powder as raw material, where Li 2 CO 3 , La 2 o 3 、MoO 3 and Dy 2 o 3 The molar ratio is 1:(1-x):4:x, x=0.01mol, 0.03mol, 0.05mol, 0.07mol, 0.9mol, 0.11mol; grind and stir the above raw materials for 20min to make them fully mixed;

[0033] (2) The mixture is packed into a corundum crucible;

[0034] (3) Put the crucible into a high-temperature electric furnace, set the heating rate to 120°C / min, set the reaction temperature to 800°C, hold the temperature for 4h, and perform calcination in an air atmosphere;

[0035] (4) After the solid phase reaction is completed, the crucible is naturally cooled to room temperature, the product is taken out, ground for 20 minutes to form a powder, and the target product is obtained after passing through a 100-mesh sieve. 3+ The doping concentrations are 1mol%, 3mol%, 5mol%, 7mol%, 9mol%, 11mol%, respectively.

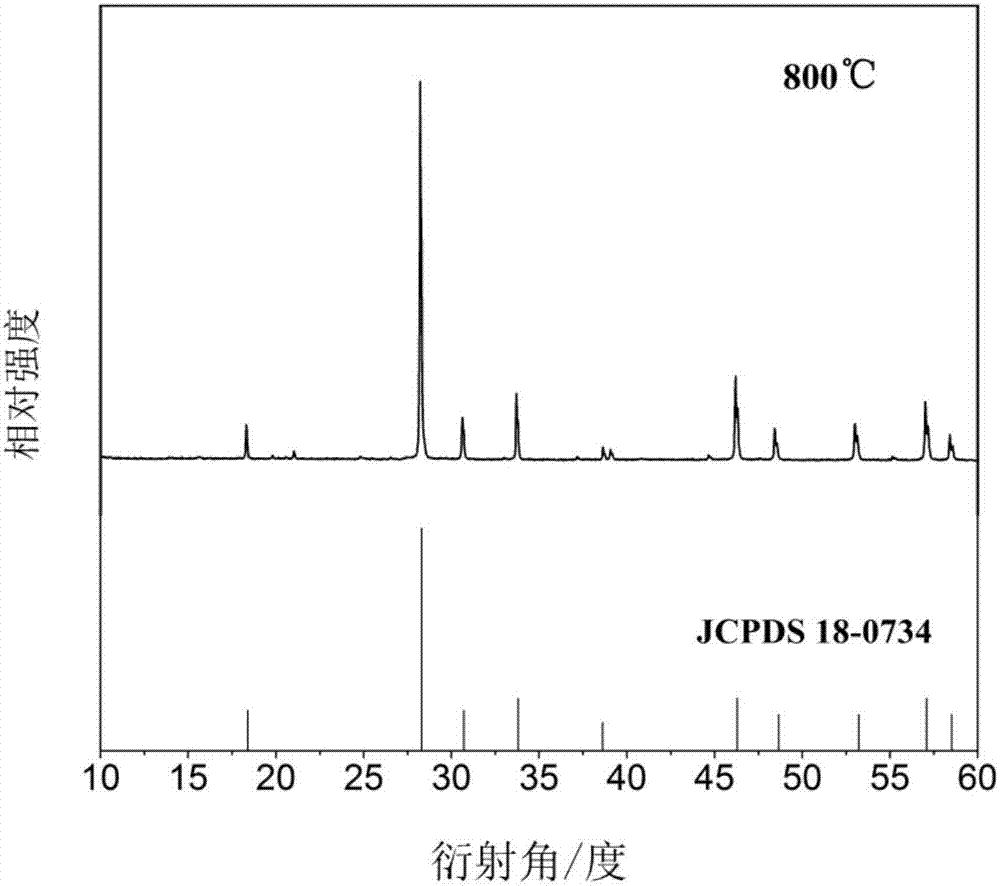

[0036] figure 1 Dy in Example 1 3+ LiLa prepared with a ...

Embodiment 2

[0039] (1) Using Li 2 CO 3 , La 2 o 3 ,MoO 3 and Dy 2 o 3 powder as raw material, where Li 2 CO 3 , La 2 o 3 、MoO 3 and Dy 2 o 3 The molar ratio is 1:(1-x):4:x, x=0.05; Grind and stir the above raw materials for 10min to make them fully mixed;

[0040] (2) The mixture is packed into a corundum crucible;

[0041] (3) Put the crucible into a high-temperature electric furnace, set the heating rate to 120°C / min, set the reaction temperature to 600°C, 700°C, 750°C, 800°C, 850°C and 900°C, respectively, and set the holding time to 4h. Carry out calcination under air atmosphere;

[0042] (4) After the solid phase reaction is completed, the crucible is naturally cooled to room temperature, the product is taken out, ground for 20 minutes to form a powder, and the target product is obtained after passing through a 100-mesh sieve. 3+ The doping concentration is 5mol%.

[0043] The obtained target product was tested, and it was found that from 750°C to 850°C, the strength ...

Embodiment 3

[0045] (1) Using Li 2 CO 3 , La 2 o 3 ,MoO 3 and Dy 2 o 3 powder as raw material, where Li 2 CO 3 , La 2 o 3 、MoO 3 and Dy 2 o 3 The molar ratio is 1: (1-x): 4: x, x = 0.01; Grind and stir the above raw materials for 20 minutes to make them fully mixed;

[0046] (2) The mixture is packed into a corundum crucible;

[0047] (3) Put the crucible into a high-temperature electric furnace, set the heating rate to 120° C. / min, set the reaction temperature to 800° C., hold the temperature for 5 hours, and perform calcination in an air atmosphere;

[0048] (4) After the solid phase reaction is completed, the crucible is naturally cooled to room temperature, the product is taken out, ground for 30 minutes to form a powder, and the target product is obtained after passing through a 100-mesh sieve. 3+ The doping concentration is 1mol%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com