Low-temperature preparation method of low-dielectric microwave medium ceramic

A technology of microwave dielectric ceramics and low temperature, applied in the field of microwave dielectric ceramics, can solve the problems of high sintering temperature, inability to apply LTCC, and limit wide application, etc., to achieve the effects of promoting ceramic sintering, improving compactness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

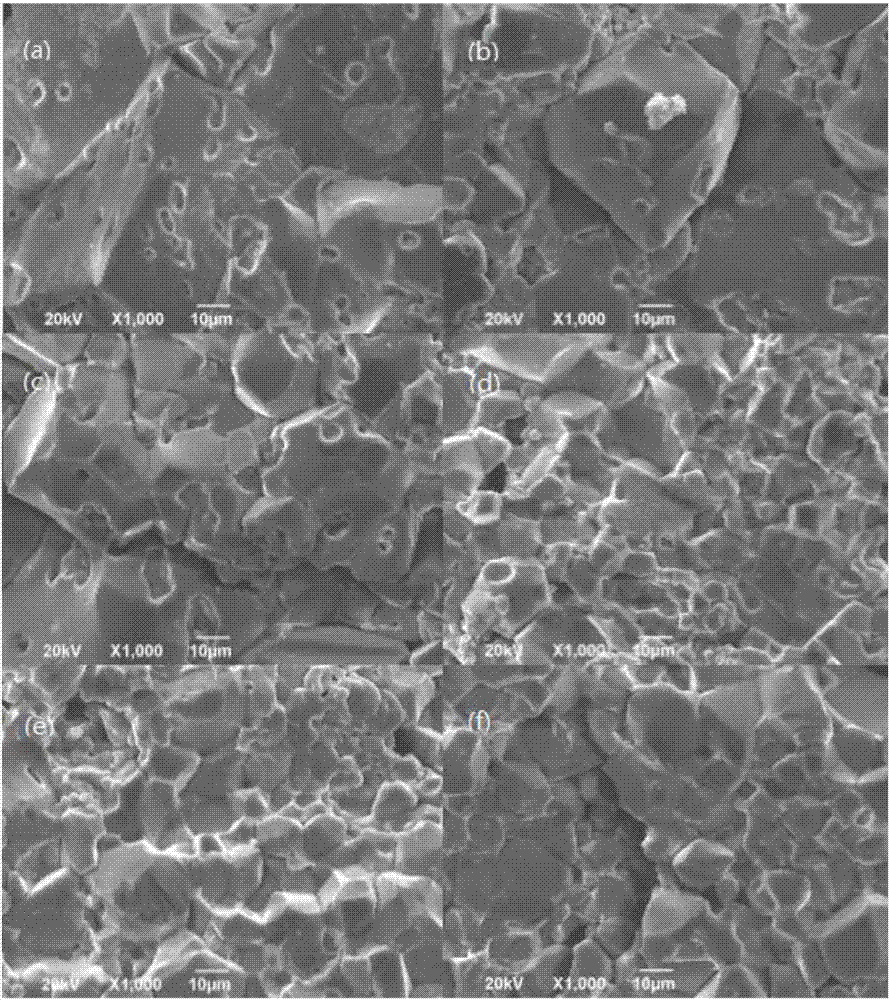

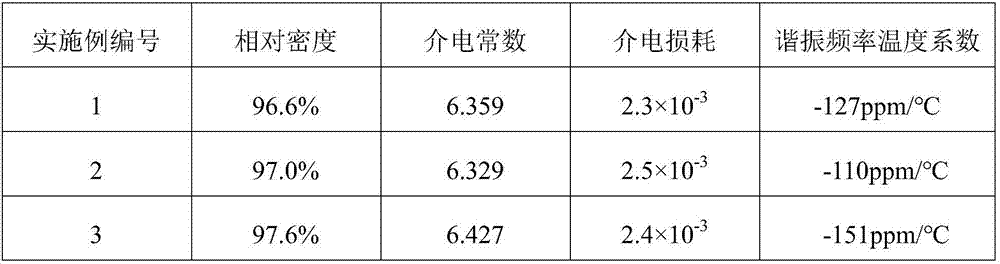

Embodiment 1

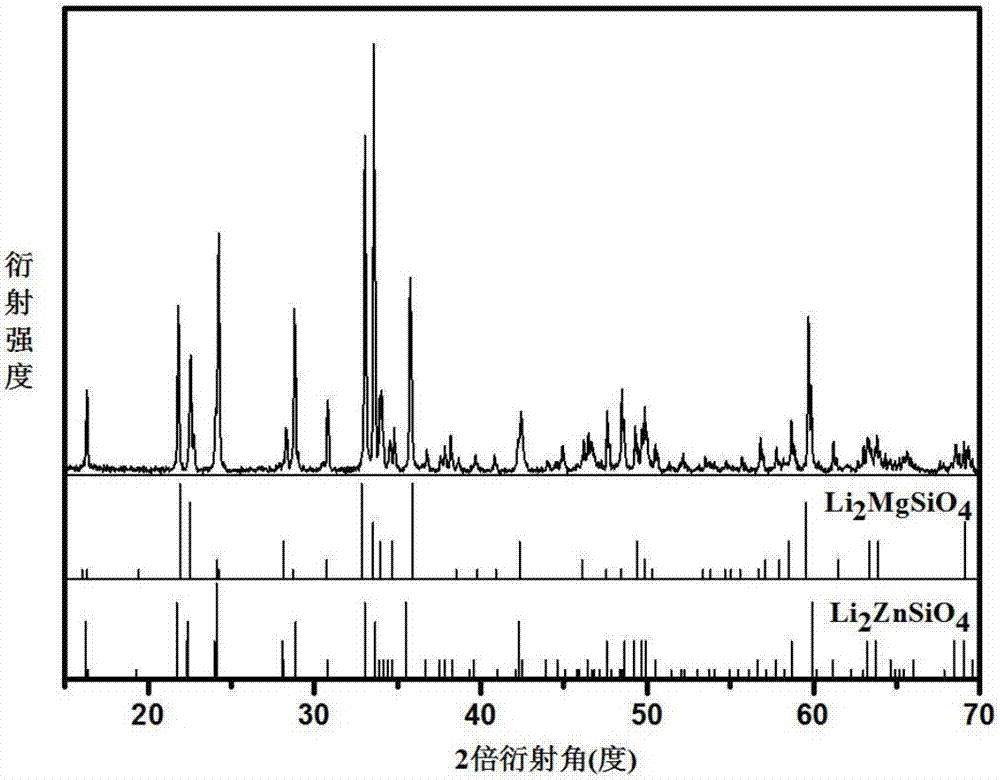

[0026] The invention discloses a low-temperature preparation method of low-medium microwave dielectric ceramics, which comprises the following steps:

[0027] Step A: ingredients; Li 2 CO 3 , ZnO, MgO, SiO 2 According to the general chemical formula Li 2 (Mg 0.8 Zn 0.2 ) SiO 4 Perform batching to form a mixture;

[0028] Step B: ball milling; put the mixture prepared in step A into a polytetrafluoroethylene ball milling tank, use absolute ethanol as a dispersant, and zirconia balls as a ball milling medium, wherein: the mass ratio of mixture: grinding balls: absolute ethanol 1: 5: 1.5, ball milled on a planetary ball mill for 12 hours; obtain the first ball mill that is uniformly mixed;

[0029] Step C: drying and sieving; putting the first ball abrasive obtained in step B into an oven at 80°C to dry to obtain the first dry powder;

[0030] Step D: pre-burning; place the dry powder obtained in step C on Al 2 o 3 In a crucible, pre-fired for 4 hours under an atmospher...

Embodiment 2

[0036] The invention discloses a low-temperature preparation method of low-medium microwave dielectric ceramics, which comprises the following steps:

[0037] Step A: ingredients; Li 2 CO 3 , ZnO, MgO, SiO 2 According to the general chemical formula Li 2 (Mg 0.8 Zn 0.2 ) SiO 4 Perform batching to form a mixture;

[0038] Step B: ball milling; put the mixture prepared in step A into a polytetrafluoroethylene ball milling tank, use absolute ethanol as a dispersant, and zirconia balls as a ball milling medium, wherein: the mass ratio of mixture: grinding balls: absolute ethanol 1: 5: 1.5, ball milled on a planetary ball mill for 12 hours; obtain the first ball mill that is uniformly mixed;

[0039] Step C: drying and sieving; putting the first ball abrasive obtained in step B into an oven at 80°C to dry to obtain the first dry powder;

[0040] Step D: pre-burning; place the dry powder obtained in step C on Al 2 o 3 In a crucible, pre-fired for 4 hours under an atmospher...

Embodiment 3

[0046] The invention discloses a low-temperature preparation method of low-medium microwave dielectric ceramics, which comprises the following steps:

[0047] Step A: ingredients; Li 2 CO 3 , ZnO, MgO, SiO 2 According to the general chemical formula Li 2 (Mg 0.8 Zn 0.2 ) SiO 4 Perform batching to form a mixture;

[0048] Step B: ball milling; put the mixture prepared in step A into a polytetrafluoroethylene ball milling tank, use absolute ethanol as a dispersant, and zirconia balls as a ball milling medium, wherein: the mass ratio of mixture: grinding balls: absolute ethanol 1: 3: 2, ball milled on a planetary ball mill for 6 hours; obtain the first ball mill that is uniformly mixed;

[0049] Step C: drying and sieving; putting the first ball abrasive obtained in step B into an oven at 80°C to dry to obtain the first dry powder;

[0050] Step D: pre-burning; place the dry powder obtained in step C on Al 2 o 3 In a crucible, pre-fired for 4 hours under an atmospheric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com