Efficient hydrolytic recycling technology and device for AlN in aluminum ash

An aluminum ash, high-efficiency technology, applied in the field of high-efficiency aluminum ash AlN hydrolysis recycling process and its equipment, can solve the problems of large volume of ammonia absorption tower, large ammonia volatilization, low ammonia concentration, etc., to expand the reaction area , Simple operation, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

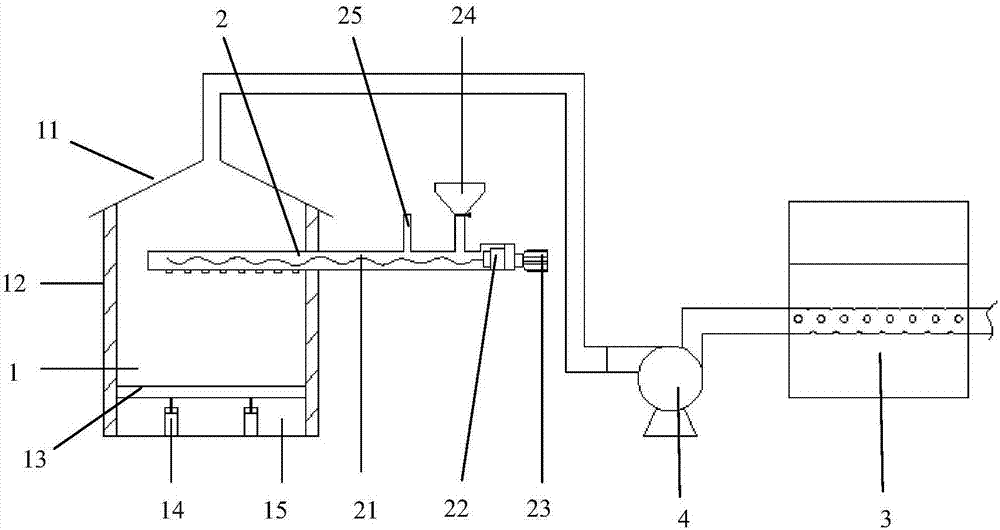

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] A high-efficiency AlN hydrolysis recovery process in aluminum ash, characterized in that the aluminum ash and water collected by the dust collector from the aluminum ash or flue gas produced by aluminum melting and casting are in a mass ratio greater than or equal to 1:0.3 and less than 1:1 Mix and prepare into mud, and react under normal temperature conditions; the ammonia gas generated by the reaction is pumped into the ammonia absorption tank through the air pump to prepare ammonia water.

[0022] In this embodiment, because the aluminum ash is mixed with water to form a mud, and the reaction of AlN and water will generate aluminum hydroxide and ammonia, which is an exothermic reaction, so the heat of the reaction is maintained and maintained in the muddy state of the material. As the reaction continues to accumulate, the reaction betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com