Photocuring 3D printing machine based on FDM printing technology

A 3D printer and photo-curing technology, applied in the field of 3D printing, can solve the problems of high printing cost of SLA and poor printing accuracy of FDM, and achieve the effect of improving printing accuracy and printing quality, accurate printing layer accuracy, and improving printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

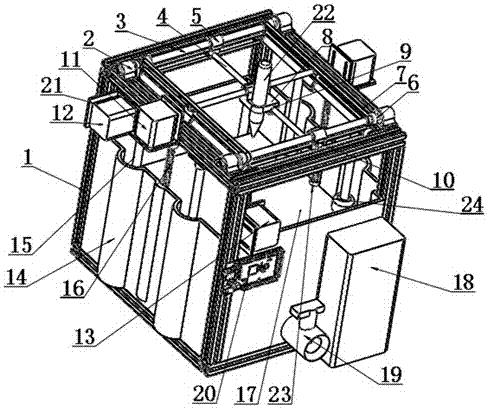

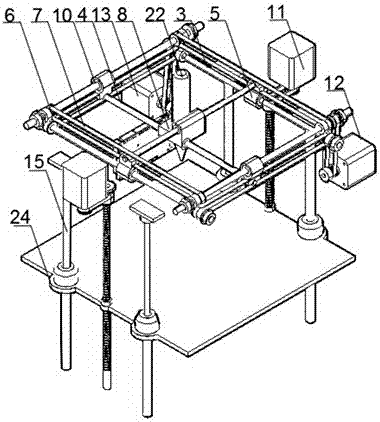

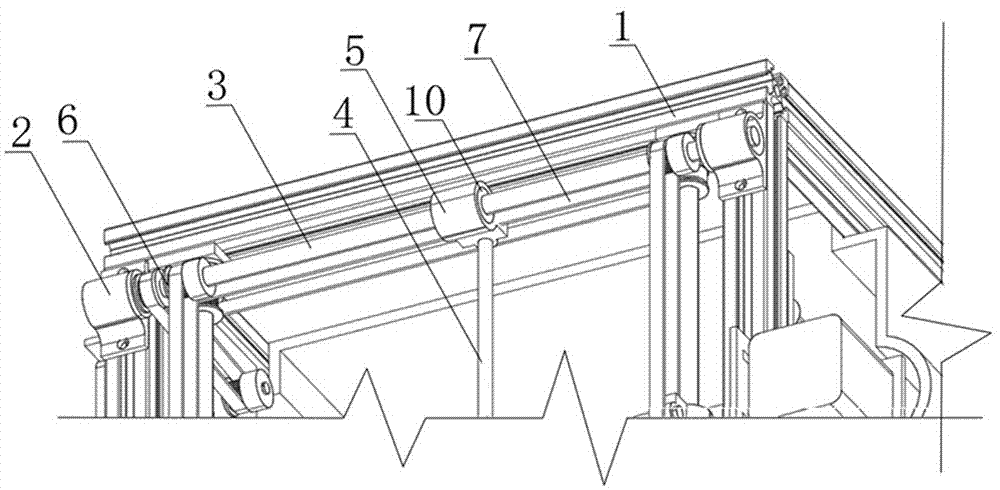

[0030] combined with figure 1 , attached figure 2 , attached image 3 , attached Figure 4 As shown, a light-curing 3D printer based on FDM printing technology includes a light-filtering housing 25, an aluminum square tube 1, and the aluminum square tube 1 is fixedly connected to form a square printer frame. Any one of the printer frames composed of the aluminum square tube 1 The four corners of the outer surface are respectively fixed with two bearing housings 2 facing an included angle of 90 degrees, and an 8mm optical axis 3 is fixed between the two bearing housings 2 facing opposite to the same aluminum square tube, so Each of the 8mm optical axes 3 is equipped with a slide block 5, and the two ends of the 8mm optical axes 3 are provided with synchronous wheels 6 near the bearing housing 2, and the synchronous wheels 6 on the two mutually parallel 8mm optical axes 3 6 is provided with transmission belt 7, and described transmission belt 7 is connected with transmission...

Embodiment 2

[0037] In order to make the printing effect better and the printing model more accurate, according to the principle and structure of a light-curing 3D printer based on FDM printing technology described in Embodiment 1, combined with the attached figure 1 , attached figure 2 , attached image 3 attached, Figure 4 As shown, the outside of the printer is also provided with a filter housing 25. When the printer is working, the filter housing 25 covers the printer to isolate the external ultraviolet rays, so that the photosensitive curing material is not affected by the external light source, thereby affecting the printing quality. 10mm linear bearing 24, the 10mm linear bearing 24 is sleeved with a 10mm optical axis 15, the two ends of the 10mm optical axis 15 are fixed on the aluminum square tube 1, the 10mm optical axis 15 makes the substrate 17 fixed more firmly, the substrate 17 is more stable during the moving process, ensuring that the substrate 17 is always perpendicula...

Embodiment 3

[0039] In order to securely fix the photosensitive resin holding box 14 inside the printer without affecting the rotation of the screw rod 16, according to the principle and structure of a light-curing 3D printer based on FDM printing technology described in Embodiment 1, combined with the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 As shown, a screw nut 23 integrally connected with the substrate is also provided at the connecting portion of the substrate 17 and the screw rod 16. The screw nut 22 improves the transmission accuracy between the substrate 17 and the screw rod 16, and the photosensitive resin storage box 14 is placed in the The part connected with the screw mandrel 16 is integrally connected with a bearing, and the inside of the bearing is provided with a sealing rubber ring. The screw mandrel 16 passes through the bearing and is sealed and connected with the photosensitive resin storage box 14. The maximum moving distance is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com