Gold ion imprinting magnetic adsorbent as well as preparation method and application thereof

A magnetic adsorbent, gold ion technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of uneven binding sites of materials, time-consuming and laborious repeated grinding, and difficult elution of internal templates. Achieve the effect of simple phase separation, easy batch operation and wide pH range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

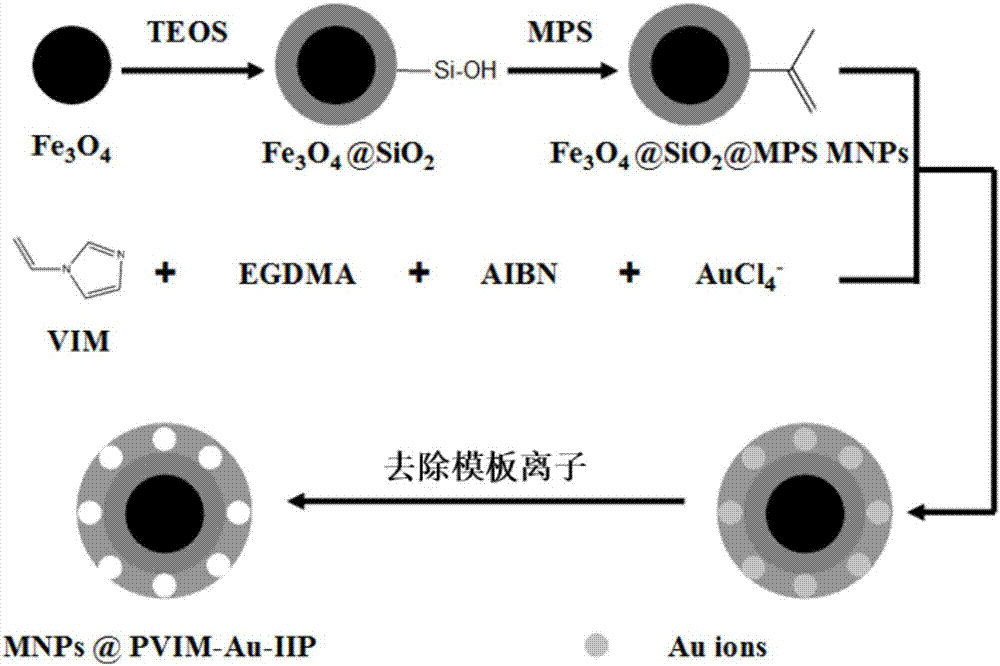

[0039] Preparation of gold ion imprinted magnetic adsorbent MNPs@PVIM-Au-IIP (ie MNPs@IIP)

[0040] The schematic diagram of the synthesis of gold ion imprinted magnetic adsorbent MNPs@PVIM-Au-IIP is shown in figure 1 As shown, the specific steps are as follows:

[0041] Step 1. Co-precipitation method to prepare magnetic Fe with a particle size of 10-20nm 3 o 4 Nanoparticles: Dissolve 11.68g of ferric chloride and 4.30g of ferrous chloride in 200mL of high-purity water, stir and heat to 85°C under nitrogen protection. Then add 20 mL of 30% NH 3 ·H 2 O, the color of the solution rapidly changed from orange to black. After reacting for half an hour, the reaction was stopped, cooled to room temperature, and the obtained nanoparticles were washed with high-purity water and ethanol in turn until neutral, and stored with high-purity water.

[0042] Step 2. Preparation of Fe with Core-Shell Structure by Silica Coupling 3 o 4 @SiO 2 @MPS Magnetic Nanoparticles (abbreviate...

Embodiment 2

[0046] Preparation of Non Imprinted Polymercoated Magnetic Adsorbent MNPs@NIP (Non Imprinted Polymercoated MNPs)

[0047] Preparation of non-imprinted polymer-coated magnetic adsorbent MNPs@NIP: The difference from Example 1 is that no chloroauric acid solution is added, and there is no need to use thiourea-HCl solution for ultrasonic cleaning to remove template ions. Other synthesis methods and The conditions are the same as the preparation method of MNPs@IIP in Example 1.

Embodiment 3

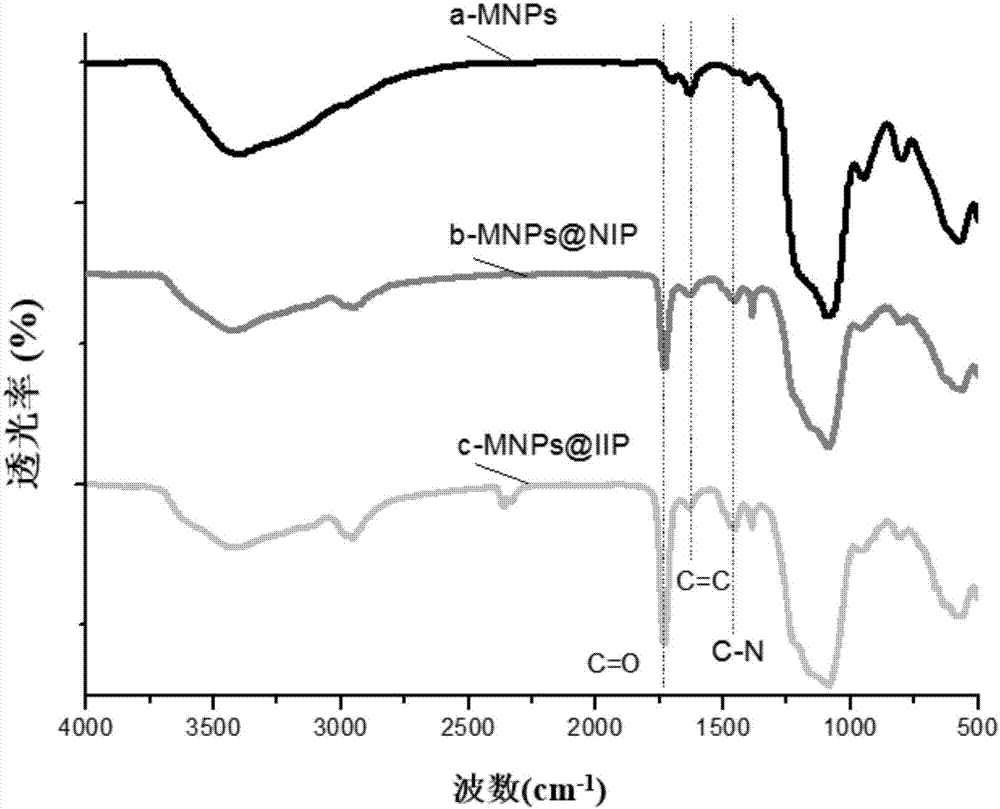

[0048] Characterization of MNPs, MNPs@IIP and MNPs@NIP

[0049] The MNPs, MNPs@IIP prepared in Example 1 and the MNPs@NIP prepared in Example 2 were characterized by FT-IR spectrometer. Such as figure 2 As shown, in the infrared spectra of MNPs, MNPs@IIP and MNPs@NIP, a wavenumber of 570cm -1 left and right and 1085cm -1 The left and right absorption peaks are respectively the stretching vibration peak of the Fe-O bond and the characteristic absorption peak of the Si-O bond, indicating that the material contains magnetic Fe 3 o 4 composition, and the surface is successfully coated with SiO 2 Silicone coating. In the infrared spectrum of MNPs ( figure 2 In the middle a curve), a C=C double bond (1630cm -1 ) and C=O double bond (1701cm -1 ) characteristic absorption peak, indicating that in Fe 3 o 4 @SiO 2 Surface modification of MPS was successful. In MNPs@NIP( figure 2 Middle b curve) and MNPs@IIP ( figure 2 In the infrared spectrogram of the middle c curve)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com