Analgesic cold patch and preparation technology thereof

A preparation process, the technology of sodium polyacrylate, applied in the field of medical devices, can solve the problems that the analgesic effect cannot be exerted, the drug ingredients cannot fully penetrate into the human skin, and the analgesic effect is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

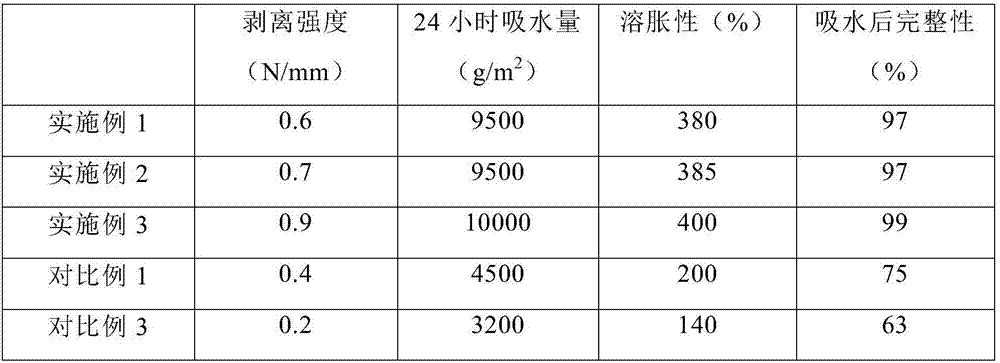

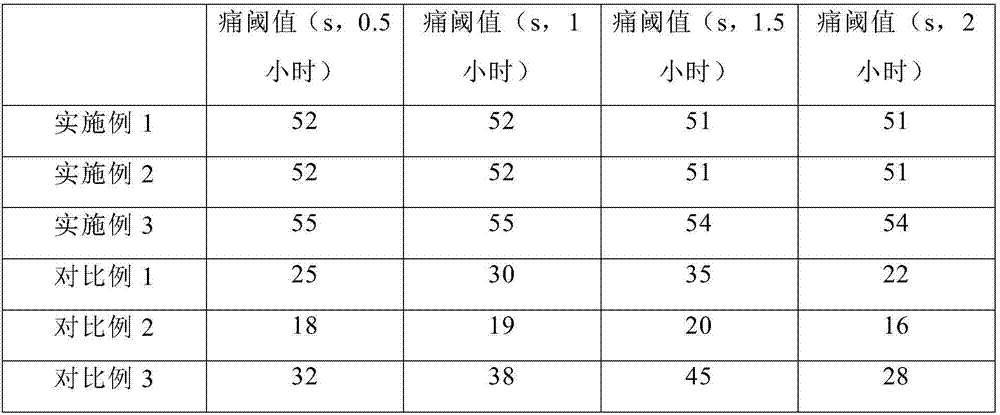

Examples

Embodiment 1

[0036] A preparation process of analgesic cold compress, the specific method is: firstly add the first part of sodium polyacrylate, glycerol, crospovidone, polymethacrylic acid and iron oxide black into glycerin to make an oil phase; Then tartaric acid, preservatives, the second part of sodium polyacrylate, traditional Chinese medicine extract, honey and water are mixed, supplemented with penetration enhancer, stabilizer, wintergreen oil, menthol and thermal agent to make the water phase; finally The oil phase and the water phase are vacuum mixed to obtain a hydrogel matrix, coated, cut, packaged, and solidified in a bag; wherein, the mass ratio of the first part of sodium polyacrylate to the second part of sodium polyacrylate is 5:3.

[0037] Specific steps are as follows:

[0038] (1) Add the first part of sodium polyacrylate, glycerol, crospovidone, polymethacrylic acid and iron oxide black into glycerin, and mix well to obtain an oil phase;

[0039] (2) After mixing the p...

Embodiment 2

[0054] A preparation process of analgesic cold compress, the specific method is: firstly add the first part of sodium polyacrylate, glycerol, crospovidone, polymethacrylic acid and iron oxide black into glycerin to make an oil phase; Then tartaric acid, preservatives, the second part of sodium polyacrylate, traditional Chinese medicine extract, honey and water are mixed, supplemented with penetration enhancer, stabilizer, wintergreen oil, menthol and thermal agent to make the water phase; finally The oil phase and the water phase are vacuum mixed to obtain a hydrogel matrix, coated, cut, packaged, and solidified in a bag; the mass ratio of the first part of sodium polyacrylate to the second part of sodium polyacrylate is 7:6.

[0055] Specific steps are as follows:

[0056] (1) Add the first part of sodium polyacrylate, glycerol, crospovidone, polymethacrylic acid and iron oxide black into glycerin, and mix well to obtain an oil phase;

[0057] (2) After mixing the penetratio...

Embodiment 3

[0072] A preparation process of analgesic cold compress, the specific method is: firstly add the first part of sodium polyacrylate, glycerol, crospovidone, polymethacrylic acid and iron oxide black into glycerin to make an oil phase; Then tartaric acid, preservatives, the second part of sodium polyacrylate, traditional Chinese medicine extract, honey and water are mixed, supplemented with penetration enhancer, stabilizer, wintergreen oil, menthol and thermal agent to make the water phase; finally The oil phase and the water phase are vacuum mixed to obtain a hydrogel matrix, coated, cut, packaged, and solidified in a bag; the mass ratio of the first part of sodium polyacrylate to the second part of sodium polyacrylate is 6:5.

[0073] Specific steps are as follows:

[0074] (1) Add the first part of sodium polyacrylate, glycerol, crospovidone, polymethacrylic acid and iron oxide black into glycerin, and mix well to obtain an oil phase;

[0075] (2) After mixing the penetratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com