Polishing liquid for metal 3D printing workpiece and preparation method of polishing liquid

A technology of 3D printing and polishing fluid, which is applied in the field of 3D printing, can solve the problems of difficult surface treatment, etc., and achieve the effect of low cost, good smoothing effect and bright effect, and low roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

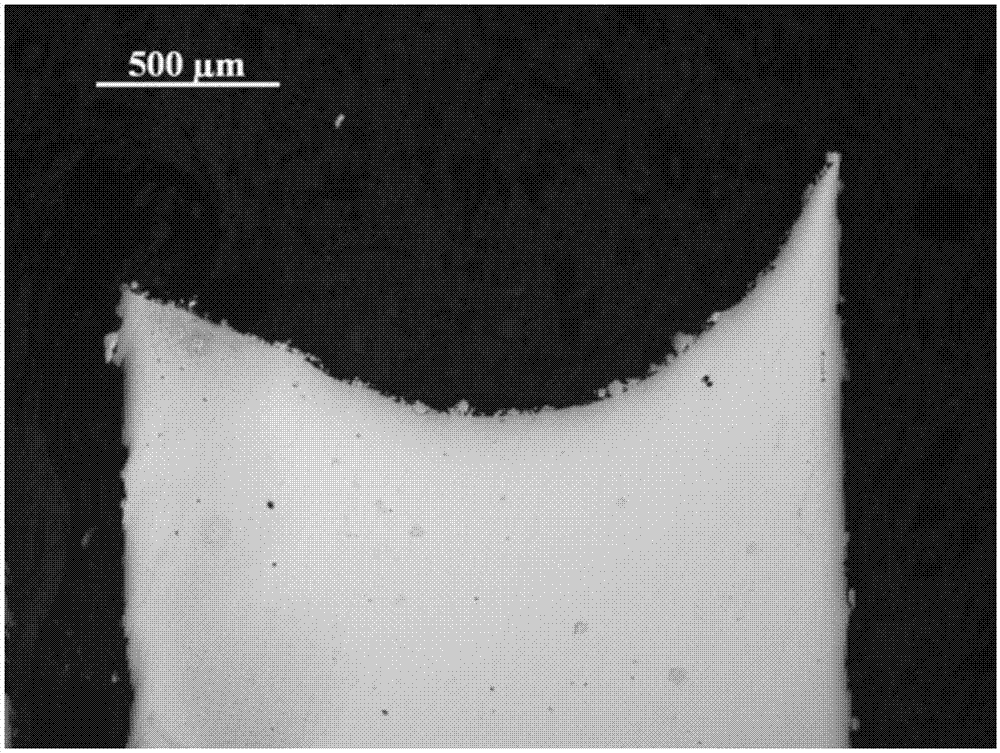

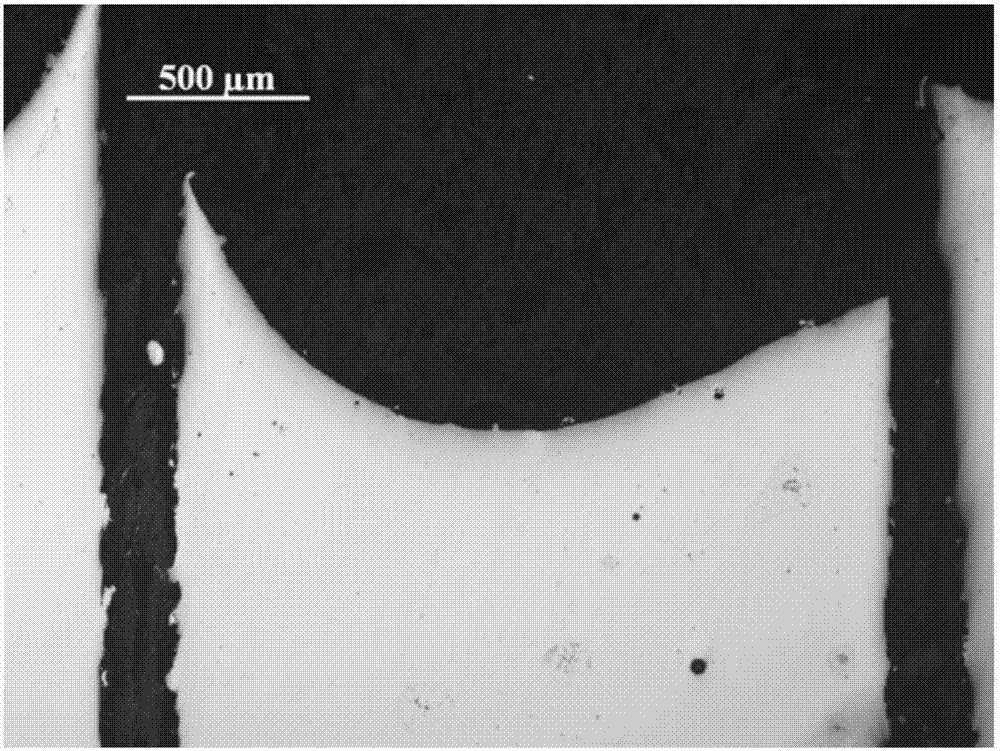

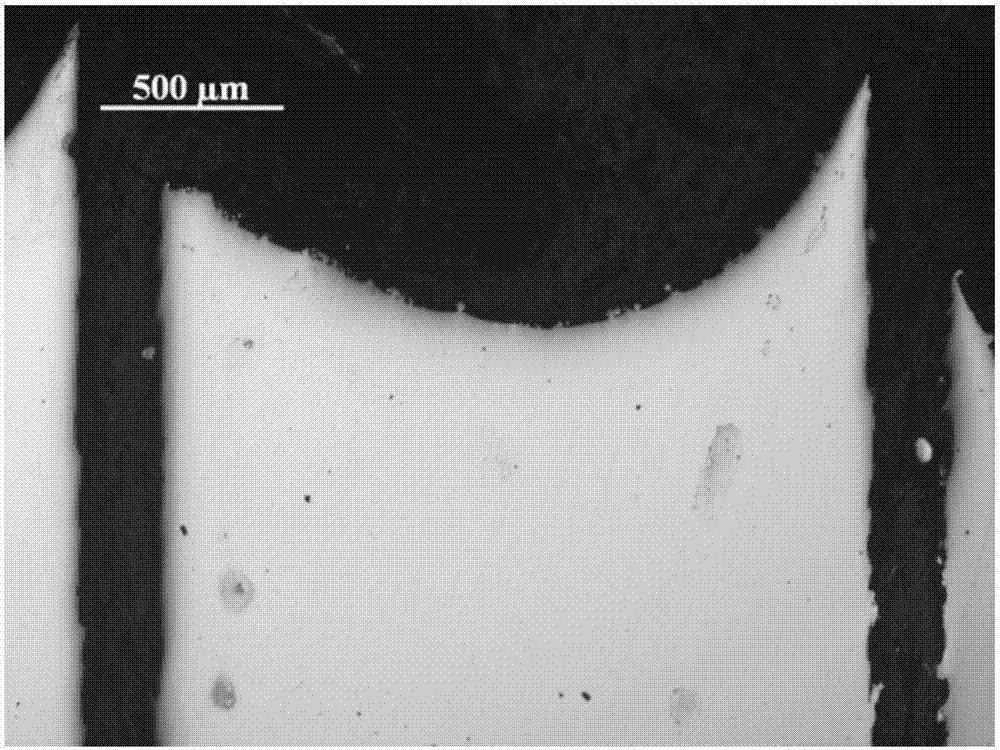

Image

Examples

Embodiment 1

[0064] A kind of polishing solution for metal 3D printing workpiece provided by this embodiment, it comprises: H 3 PO 4 200mL / L, HCl80mL / L, HNO 3 50mL / L, hydrogen fluoride 150mL / L, sulfosalicylic acid 5g / L, hexamethylenetetramine 1g / L, FeC1 3 ·6H 2 O20g / L.

[0065] Its preparation method is as follows: measure 200mL / L phosphoric acid with a graduated cylinder; measure 80mL / L hydrochloric acid with a graduated cylinder, and slowly inject it into a beaker while stirring, and the process is operated in a fume hood; measure 50mL / L nitric acid with a graduated cylinder, and stir while stirring. Slowly pour into the beaker, the process is operated in a fume hood; measure 150mL / L hydrofluoric acid with a measuring cylinder, slowly pour into the beaker while stirring, and the process is operated in a fume hood; smash the solid block ferric chloride hexahydrate as much as possible , 4g at a time, slowly added to the beaker solution in 5 times and stirred evenly, put the beaker in...

Embodiment 2

[0067] A kind of polishing solution for metal 3D printing workpiece provided by this embodiment, it comprises: H 3 PO 4 600mL / L, HCl350mL / L, HNO 3 500mL / L, hydrogen fluoride 350mL / L, sulfosalicylic acid 20g / L, hexamethylenetetramine 5g / L, FeC1 3 ·6H 2 O 50g / L.

[0068] Its preparation method is as follows: measure 600mL / L phosphoric acid with a graduated cylinder; measure 350mL / L hydrochloric acid with a graduated cylinder, and slowly inject it into a beaker while stirring, and the process is operated in a fume hood; measure 500mL / L nitric acid with a graduated cylinder, and stir while stirring Slowly pour into the beaker, the process is operated in a fume hood; measure 350mL / L hydrofluoric acid with a graduated cylinder, slowly pour into the beaker while stirring, and the process is operated in a fume hood; smash the solid block ferric chloride hexahydrate as much as possible , 10g at a time, slowly add to the beaker solution in 5 times and stir the solution evenly, put...

Embodiment 3

[0070] A kind of polishing solution for metal 3D printing workpiece provided by this embodiment, it comprises: H 3 PO 4 300mL / L, HCl100mL / L, HNO 3 400mL / L, hydrogen fluoride 200mL / L, sulfosalicylic acid 15g / L, hexamethylenetetramine 4g / L, FeC1 3 ·6H 2 O 30g / L.

[0071] Its preparation method is as follows: measure 300mL / L phosphoric acid with a graduated cylinder; measure 100mL / L hydrochloric acid with a graduated cylinder, and slowly inject it into a beaker while stirring, and the process is operated in a fume hood; measure 400mL / L nitric acid with a graduated cylinder, and stir while stirring. Slowly pour into the beaker, the process is operated in a fume hood; measure 200mL / L hydrofluoric acid with a graduated cylinder, slowly pour into the beaker while stirring, and the process is operated in a fume hood; smash the solid block ferric chloride hexahydrate as much as possible , 10g at a time, slowly add to the beaker solution in 3 times and stir the solution evenly, pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com